Other Types Of Labeling Machines

|

Model |

|||

|

Labeling accuracy |

+1mm |

+1mm |

±1.5mm |

|

Production Speed |

50-80 boxes per minute |

10-50m/min |

10~25pcs/min |

|

Paper roll diameter |

Φ 76 mm Φ 320 (maximum) |

Φ 76 mm Φ 320 (maximum) |

Φ 76 mm Φ 320 |

|

Power |

1200W |

900W |

600W |

|

Voltage specification |

220V 50/60HZ |

AC220V 50/60HZ |

220V 50HZ |

|

Weight |

200KG |

80KG |

48kg |

|

Dimension (L×W×H) |

1800*900*1300mm |

1000*750*1300mm |

850*410*1500mm |

Box Corner Marking Machine

The Box Corner Marking Machine is designed to handle products with challenging shapes, such as cartons with sharp edges or irregular corners. Traditional labeling machines often struggle to maintain alignment and adhesion on such surfaces, leading to inconsistent labeling quality. Our box corner marking machines utilize advanced alignment technology and precision rollers to ensure accurate label placement even on complex shapes. They are suitable for applications in food packaging, pharmaceuticals, and consumer goods industries where corner marking or edge labeling is required.

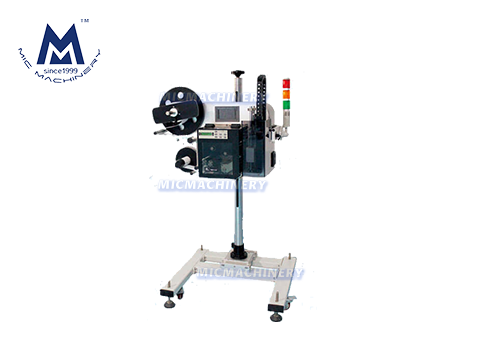

High Speed Wiring Labeling Machines

The High Speed Wiring Labeling Machine is engineered to label wires, cables, and tubing with high speed and precision. These machines can accommodate various wire sizes and label types, including self-adhesive sleeves, wrap-around labels, or heat-shrink labels. With integrated tension control systems and automatic feeding mechanisms, our high speed wiring labeling machines ensure smooth, uninterrupted labeling even in high-volume production environments. They are ideal for electrical, automotive, and electronics manufacturing where consistent wire identification is essential.

Pneumatic Marking Machines

The Pneumatic Marking Machine leverages compressed air to apply labels, stamps, or markings onto products quickly and reliably. These machines are highly versatile and can be used on a wide range of materials, including metal, plastic, glass, and cardboard. Pneumatic marking machines offer precise control over labeling speed and pressure, making them suitable for applications that require durable, high-quality marks. They are commonly used in industrial manufacturing, logistics, and packaging operations where permanent or semi-permanent labeling is necessary.

Applications

These specialized labeling machines find applications across multiple industries:

● Food and Beverage: Labeling cartons, bottles, or packaging with precise edge or corner placement.

● Pharmaceuticals: Ensuring accurate labeling on vials, boxes, and medical devices.● Electronics and Electrical: Identifying wires, cables, and components in high-volume production lines.

● Automotive: Labeling wiring harnesses, tubing, and other vehicle components.

● Industrial Manufacturing: Applying durable labels or marks to metal, plastic, and other materials.

● Logistics and Packaging: Improving traceability with precise markings for shipment and inventory management.

By employing the right machine for specific tasks, manufacturers can increase efficiency, maintain high product quality, and reduce operational costs.

Mic Machinery’s other types of labeling machines are designed with performance and reliability in mind. Key advantages include:

● High Accuracy and Consistency: Each machine ensures precise label placement, minimizing errors and wastage.

● Adaptability: Machines can handle diverse product shapes, sizes, and materials without compromising efficiency.

●User-Friendly Operation: Simple touch-screen interfaces and intuitive controls allow operators to quickly set up and manage labeling processes.

● Durable Construction: Built with high-quality materials and components, these machines provide long-term reliability and minimal maintenance.

● Integration Capabilities: Easily integrated into existing production lines, supporting automated and semi-automated workflows.

Specifically, Box Corner Marking Machines excel at labeling cartons and packages with sharp edges, High Speed Wiring Labeling Machines achieve remarkable throughput for wire and cable applications, and Pneumatic Marking Machines offer flexibility and speed for industrial marking needs.

Mic Machinery is a leading manufacturer of labeling machines and packaging solutions, committed to providing high-quality, innovative, and reliable equipment. With decades of experience in the industry, we specialize in a wide range of labeling solutions, from standard automatic labeling machines to specialized Box Corner Marking Machines, High Speed Wiring Labeling Machines, and Pneumatic Marking Machines.

Our machines are designed to meet diverse industrial needs, incorporating the latest technology for precise labeling, minimal downtime, and easy integration into production lines. We also offer comprehensive after-sales support, including installation guidance, maintenance services, and training, ensuring that clients maximize the value of their investment.

Conclusion

The demand for precise, efficient, and versatile labeling solutions continues to grow in today’s competitive manufacturing environment. Other types of labeling machines offered by Mic Machinery, including Box Corner Marking Machines, High Speed Wiring Labeling Machines, and Pneumatic Marking Machines, provide effective solutions for a variety of industrial and packaging applications.

By choosing Mic Machinery, businesses gain access to cutting-edge labeling technology, exceptional performance, and reliable support. Whether your production line requires labeling cartons with sharp corners, wires at high speed, or industrial components with durable markings, Mic Machinery has the right solution to enhance your productivity and ensure labeling accuracy.