Technical Introduction to Emulsifying Mixers and Machines

|

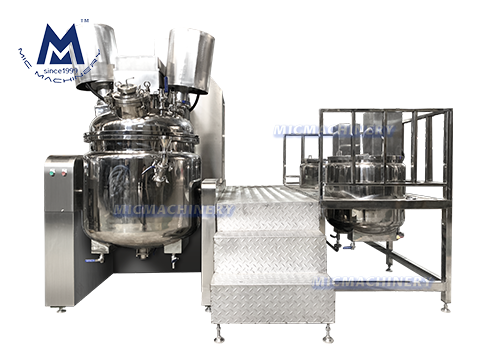

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

Emulsifying mixers are specialized devices designed to create stable emulsions by thoroughly blending two immiscible liquids, such as oil and water. These mixers work by applying shear force, which breaks down the liquid particles and disperses them uniformly throughout the mixture. The result is a consistent product with a smooth texture and homogenous appearance. Emulsifying mixers are widely used in the food, cosmetic, pharmaceutical, and chemical industries, where precise mixing and emulsification are critical.

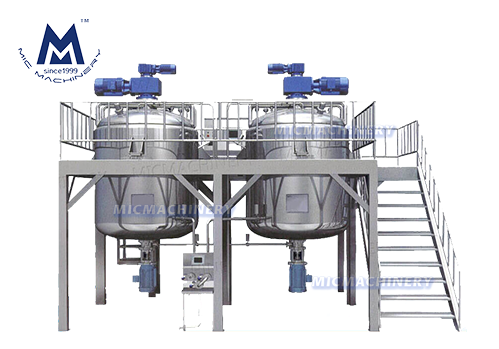

Emulsifying Machines

Emulsifying machines are versatile tools used to blend, mix, and emulsify a variety of substances. These machines are equipped with high-speed rotors and stators that create a powerful shearing action, ensuring even distribution of all components. The key performance indicators of an emulsifying machine include efficiency, stability, and the ability to handle various viscosities. They are indispensable in processes that require the integration of ingredients with different physical properties.

Emulsifying Equipment: The term emulsifying equipment encompasses a range of devices, including mixers, homogenizers, and specialized machines designed for emulsification. This equipment is engineered to deliver precise control over the mixing process, ensuring that the final product meets the desired specifications. High-quality emulsifying equipment is essential for maintaining consistency and quality in production.

Emulsifying Mixer Machine: An emulsifying mixer machine combines the functionalities of a mixer and an emulsifier, providing a comprehensive solution for blending and emulsification. These machines are particularly useful in the production of creams, lotions, sauces, and other products that require a smooth and consistent texture. The design and technology of emulsifying mixer machines ensure efficient operation, reducing production time and costs.

Emulsifying Machine Manufacture and Pricing

When considering the acquisition of emulsifying machinery, understanding the aspects of manufacturing and pricing is crucial. The China emulsifying machine manufacture price offers competitive options due to the country's advanced manufacturing capabilities and cost-effective production. China is a leading hub for emulsifying machine manufacture, offering a wide range of equipment tailored to various industrial needs. The emulsifying machine manufacture price can vary significantly based on factors such as machine specifications, capacity, and additional features.

For businesses looking to invest in reliable emulsifying equipment, choosing a reputable emulsifying machine manufacturer is key. A trusted manufacturer not only provides high-quality machines but also offers excellent after-sales support, including maintenance, spare parts, and technical assistance. The right manufacturer can offer customized solutions that meet specific industry requirements, ensuring optimal performance and durability of the equipment.

In conclusion, emulsifying technology plays a vital role in numerous industries, and selecting the appropriate machinery is essential for achieving high-quality products. Whether it's emulsifying mixers, emulsifying machines, or specialized emulsifying equipment, the choice of equipment can significantly impact the efficiency and outcome of the production process. By understanding the various options available, including China emulsifying machine manufacture price and selecting the right emulsifying machine manufacturer, businesses can ensure they have the best tools for the job. Investing in the right emulsifying machinery not only enhances product quality but also improves overall production efficiency and cost-effectiveness.

In industries where precise emulsification is a critical process, the emulsifying machine takes center stage as a powerful tool. This technical article explores the features, benefits, and applications of emulsifying machines, shedding light on their significance in achieving superior emulsion quality and stability.

Emulsifying Machine:

An emulsifying machine is a specialized piece of equipment designed to facilitate the emulsification process. This machine utilizes mechanical force and shear to break down larger droplets and disperse them uniformly throughout the mixture. With precise control over parameters such as speed, temperature, and mixing time, the emulsifying machine ensures efficient and consistent emulsification in various industries, including cosmetics, food, pharmaceuticals, and chemicals.

Emulsifying Mixer Machine:

An emulsifying mixer machine combines the functions of mixing and emulsifying in a single device. This versatile machine offers efficient blending of two or more immiscible liquids, resulting in stable and homogeneous emulsions. With adjustable speed settings, temperature control, and advanced mixing technologies, the emulsifying mixer machine enables manufacturers to achieve optimal emulsion quality and consistency in their products.

Emulsifying Mixer:

An emulsifying mixer is a key component of emulsion production processes. This machine operates by subjecting the mixture to intense shear forces, effectively breaking down large droplets and promoting the dispersion of immiscible liquids. The emulsifying mixer ensures uniformity, stability, and superior texture in emulsion-based products, making it an essential tool in industries that require precise control over emulsification.

Vacuum Emulsifying Machine:

A vacuum emulsifying machine takes emulsion production to the next level by incorporating a vacuum system into the emulsification process. This machine eliminates air bubbles and reduces oxidation, resulting in emulsions with improved stability, extended shelf life, and enhanced product integrity. The vacuum emulsifying machine finds wide application in industries such as cosmetics, pharmaceuticals, and food manufacturing.

Vacuum Emulsifying Mixer Machine:

The vacuum emulsifying mixer machine combines the benefits of a vacuum system with efficient mixing and emulsifying capabilities. This advanced machine operates under reduced pressure conditions, ensuring the elimination of air bubbles and enhanced emulsion stability. The vacuum emulsifying mixer machine offers precise control over emulsification parameters, resulting in consistent and high-quality emulsions for industries requiring superior product performance.

Vacuum Emulsifying Mixer Price:

The price of a vacuum emulsifying mixer can vary depending on factors such as capacity, features, and the manufacturer. Factors like the quality of materials used, technological advancements, and additional functionalities also impact the price. It's advisable for buyers to consider their specific requirements and budget while comparing prices from reputable manufacturers to make an informed decision.

Vacuum Emulsifying Mixer:

A vacuum emulsifying mixer is a versatile and high-performance machine used in emulsion production. By operating under vacuum conditions, this mixer minimizes air entrapment and ensures the production of stable and uniform emulsions. The vacuum emulsifying mixer is commonly used in industries such as cosmetics, pharmaceuticals, and food, where precise control over emulsion quality and stability is crucial.

Conclusion

Emulsifying machines play a vital role in achieving efficient and precise emulsification processes across various industries. Whether it's an emulsifying machine, emulsifying mixer machine, or vacuum emulsifying machine, these advanced devices enable manufacturers to produce stable and high-quality emulsions. By incorporating these machines into their production processes, industries can achieve superior emulsion performance, enhanced product stability, and a competitive edge in the market.