Technical Introduction to Emulsifier Mixers and Equipment

|

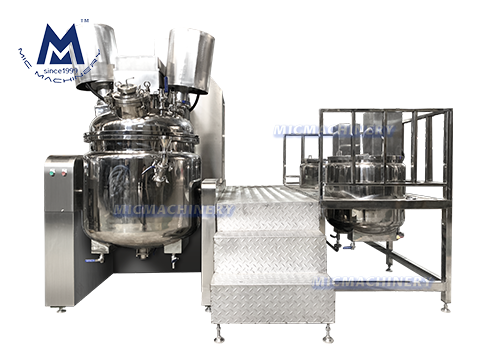

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

An emulsifier mixer is a sophisticated device engineered to facilitate the process of emulsification. This process involves dispersing one liquid into another immiscible liquid to form a stable emulsion. The performance of an emulsifier mixer is critical in producing products with consistent texture, flavor, and shelf-life. The design of the mixer, including its rotor-stator assembly and speed, plays a pivotal role in the efficiency of the emulsification process.

Key Components and Types of Emulsifier Equipment

Emulsifier equipment includes various machines and tools, such as the mixer emulsifier, emulsifier mixer machine, and emulsifier tank. These devices differ in size, design, and capacity, catering to different production scales and requirements. For instance, a food emulsifier machine is specifically designed for the food industry, ensuring that products like sauces, dressings, and creams achieve the desired consistency and stability.

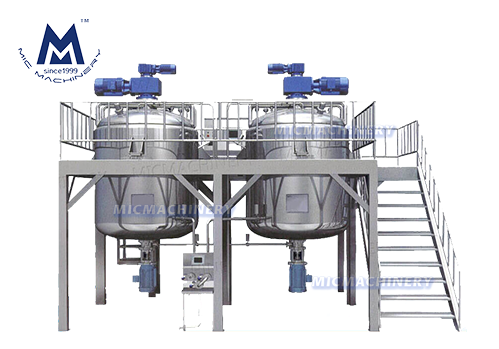

The emulsifier device and emulsification machine are integral to industries that require precise mixing and emulsification. These machines can be customized with different rotor-stator combinations, which influence the size of the droplets in the emulsion and, consequently, the stability and texture of the final product. The emulsification tank is another critical component, providing a controlled environment for the emulsification process, often equipped with temperature control and agitation systems.

The emulsion machine and emulsifier machine are key components in the production line of various industries. These machines must be robust, efficient, and capable of producing stable emulsions consistently. The choice of emulsification equipment often depends on the specific requirements of the product, such as viscosity, particle size, and production volume.

When selecting an emulsifier mixer or related equipment, factors such as ease of cleaning, maintenance, and scalability are crucial considerations. The equipment should comply with industry standards and regulations, particularly in the food and pharmaceutical sectors, where hygiene and safety are paramount.

Performance and Applications of Emulsification Equipment

The performance of emulsification equipment is evaluated based on several factors, including the size distribution of droplets in the emulsion, the efficiency of mixing, and the stability of the final product. High-performance emulsifiers can produce fine emulsions with uniform droplet sizes, which are essential for the consistency and quality of products in industries such as pharmaceuticals and cosmetics.

An emulsion mixer is specifically designed to create emulsions by mixing two immiscible liquids thoroughly. These mixers are vital in industries that produce emulsified products, such as creams, lotions, and pharmaceutical suspensions. The mixer manufacturer plays a significant role in providing tailored solutions that meet specific industry needs, from small-scale laboratory mixers to large industrial emulsification systems.

In summary, emulsifier mixers and emulsifier equipment are essential for producing stable emulsions across various industries. The choice of mixer emulsifier, emulsifier mixer machine, and emulsifier tank can significantly impact the quality and consistency of the final product. High-performance emulsification equipment ensures efficient mixing and stable emulsions, meeting the specific needs of diverse applications. Whether in the food industry, pharmaceuticals, or cosmetics, the right emulsifier mixer can make a substantial difference in product quality and process efficiency.

In the realm of industrial mixing, emulsifier mixers play a crucial role in achieving uniform and stable emulsions. These machines are designed to blend two immiscible liquids, such as oil and water, into a homogeneous mixture. Emulsifier equipment encompasses a range of devices, each tailored to specific applications and industries, from food and beverage to pharmaceuticals and cosmetics.

Understanding Emulsifier Mixers

An emulsifier mixer is a sophisticated device engineered to facilitate the process of emulsification. This process involves dispersing one liquid into another immiscible liquid to form a stable emulsion. The performance of an emulsifier mixer is critical in producing products with consistent texture, flavor, and shelf-life. The design of the mixer, including its rotor-stator assembly and speed, plays a pivotal role in the efficiency of the emulsification process.

Key Components and Types of Emulsifier Equipment

Emulsifier equipment includes various machines and tools, such as the mixer emulsifier, emulsifier mixer machine, and emulsifier tank. These devices differ in size, design, and capacity, catering to different production scales and requirements. For instance, a food emulsifier machine is specifically designed for the food industry, ensuring that products like sauces, dressings, and creams achieve the desired consistency and stability.

The emulsifier device and emulsification machine are integral to industries that require precise mixing and emulsification. These machines can be customized with different rotor-stator combinations, which influence the size of the droplets in the emulsion and, consequently, the stability and texture of the final product. The emulsification tank is another critical component, providing a controlled environment for the emulsification process, often equipped with temperature control and agitation systems.

Performance and Applications of Emulsification Equipment

The performance of emulsification equipment is evaluated based on several factors, including the size distribution of droplets in the emulsion, the efficiency of mixing, and the stability of the final product. High-performance emulsifiers can produce fine emulsions with uniform droplet sizes, which are essential for the consistency and quality of products in industries such as pharmaceuticals and cosmetics.

An emulsion mixer is specifically designed to create emulsions by mixing two immiscible liquids thoroughly. These mixers are vital in industries that produce emulsified products, such as creams, lotions, and pharmaceutical suspensions. The mixer manufacturer plays a significant role in providing tailored solutions that meet specific industry needs, from small-scale laboratory mixers to large industrial emulsification systems.

Emulsion Machines and Market Considerations

The emulsion machine and emulsifier machine are key components in the production line of various industries. These machines must be robust, efficient, and capable of producing stable emulsions consistently. The choice of emulsification equipment often depends on the specific requirements of the product, such as viscosity, particle size, and production volume.

When selecting an emulsifier mixer or related equipment, factors such as ease of cleaning, maintenance, and scalability are crucial considerations. The equipment should comply with industry standards and regulations, particularly in the food and pharmaceutical sectors, where hygiene and safety are paramount.

Conclusion

In summary, emulsifier mixers and emulsifier equipment are essential for producing stable emulsions across various industries. The choice of mixer emulsifier, emulsifier mixer machine, and emulsifier tank can significantly impact the quality and consistency of the final product. High-performance emulsification equipment ensures efficient mixing and stable emulsions, meeting the specific needs of diverse applications. Whether in the food industry, pharmaceuticals, or cosmetics, the right emulsifier mixer can make a substantial difference in product quality and process efficiency.