Technical Introduction to Liquid Fillers: Performance and Key Features

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/ 50-500ML/100-1000ML/ 250-2500ML/1000-5000ML |

10-20ML/25-250ML/ 50-500ML/100-1000ML/ 250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottles/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

Liquid Filler

A liquid filler is a machine used to dispense liquid products into containers with high accuracy and consistency. These machines are essential in ensuring that each container is filled to the desired level, reducing product waste and maintaining uniformity across the production line.

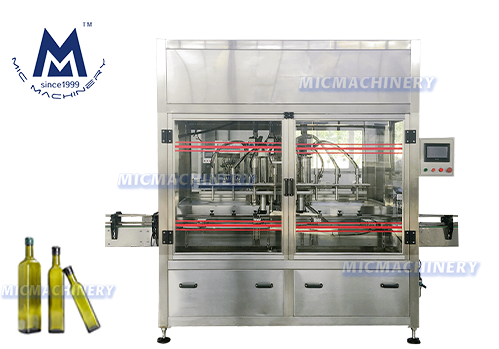

Liquid Bottle Filler

A liquid bottle filler is specifically designed for filling liquids into bottles. These machines can handle various bottle sizes and types, making them versatile for different production needs. They are commonly used in industries such as beverages, where bottled products must meet strict quality standards.

Automatic Liquid Filler

An automatic liquid filler offers a high level of automation, making it ideal for large-scale production lines. These machines are equipped with advanced sensors and controls that ensure accurate filling without the need for manual intervention. They are perfect for businesses that require high output with minimal labor costs.

Manual Liquid Filler

A manual liquid filler is a more hands-on option, where operators control the filling process. These machines are suitable for small-scale production or businesses that produce specialty products in limited quantities. They offer greater control over the filling process but may require more time and labor compared to automatic systems.

Liquid Piston Filler

A liquid piston filler uses a piston mechanism to draw and dispense liquid into containers. This type of filler is known for its accuracy and ability to handle viscous liquids, making it ideal for products like sauces, creams, and gels. Liquid piston fillers are highly reliable and can be used in both automatic and manual filling systems.

Small Liquid Filler

A small liquid filler is designed for operations that require precise filling of small volumes. These machines are compact and efficient, making them perfect for small businesses or production lines with limited space. They can be used for filling small containers such as vials, test tubes, and small bottles.

Liquid Pouch Filler

A liquid pouch filler is specialized equipment for filling liquid products into pouches. These machines are widely used in the food and beverage industry for products like sauces, juices, and liquid snacks. They are designed to ensure that pouches are filled accurately and sealed securely to prevent leaks.

Liquid Bag Filler

A liquid bag filler is similar to a pouch filler but is used for filling larger bags with liquid products. These machines are commonly used in industrial applications where large volumes of liquids need to be filled into bulk packaging. Liquid bag fillers are designed to handle high-capacity filling while maintaining precision and minimizing waste.

Performance Considerations

When selecting a liquid filler, several factors must be considered to ensure optimal performance:

1. Accuracy: The machine must fill each container with the exact amount of liquid, minimizing waste and ensuring product consistency.

2. Speed: The filling speed should match the production requirements, whether it's a small-scale operation or a high-speed production line.

3. Versatility: The ability to handle different container sizes and types is crucial for businesses that produce a variety of products.

4. Ease of Use: The machine should be easy to operate, maintain, and clean, reducing downtime and improving overall efficiency.

Choosing the right liquid filler is essential for maintaining the quality and efficiency of your production process. Whether you need a liquid bottle filler for high-speed operations or a manual liquid filler for more specialized tasks, understanding the performance characteristics of each type of machine will help you make an informed decision. By focusing on the features and capabilities of different fillers, businesses can optimize their production lines, reduce costs, and ensure the highest quality of their liquid products.