Introduction to Cosmetic Homogenizers and Emulsifiers

|

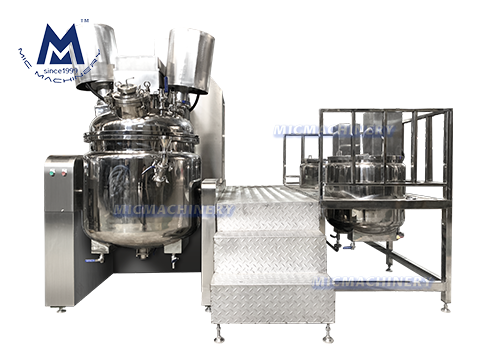

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

A cosmetic homogenizer is essential for creating uniform and stable emulsions in cosmetic products. It breaks down the size of particles and ensures that the ingredients are evenly distributed throughout the formulation. This is particularly important for products like creams, lotions, and serums, where a consistent texture is key.

The homogenizer mixer for cosmetics is a versatile tool that combines the functions of mixing and homogenizing. It helps in blending ingredients to achieve the desired viscosity and texture. The cosmetic mixer vacuum homogenizer emulsifier takes this a step further by incorporating vacuum technology, which removes air bubbles from the mixture, thus preventing oxidation and extending the shelf life of the product.

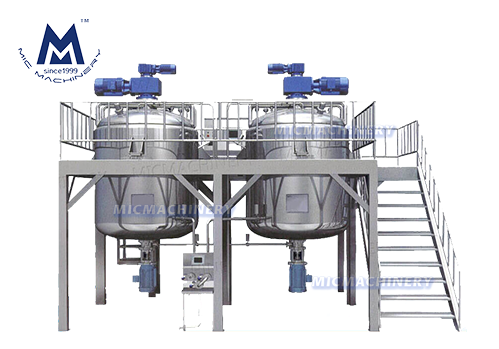

For commercial and industrial applications, commercial emulsifiers and industrial emulsifiers are used to produce large batches of cosmetic products. These machines are designed to handle high volumes and deliver consistent results, making them indispensable in large-scale cosmetic manufacturing.

The china cosmetic vacuum mixer emulsifier is a notable example of advanced technology in the field, offering high performance and efficiency. Similarly, the cosmetic vacuum mixer emulsifier ensures that the mixing process is carried out under vacuum conditions, leading to superior product quality.

Types and Applications

Cosmetic homogenizer mixers are available in various configurations, including high-shear and ultrasonic models, to cater to different needs. These mixers are critical for producing high-quality cosmetic formulations with consistent texture and appearance.

For larger-scale operations, industrial mixer homogenizers and industrial homogenizers are employed. These robust machines are designed to handle large volumes of product, making them ideal for commercial production. The term homogenizer industrial refers to heavy-duty equipment capable of processing significant quantities of materials while maintaining efficiency and uniformity.

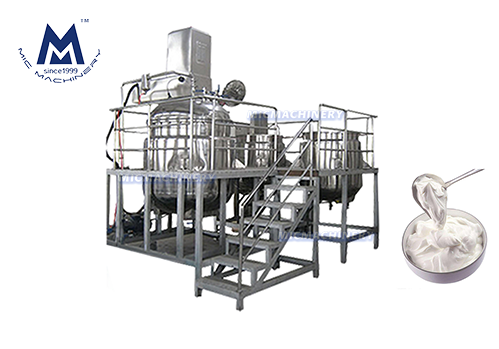

Cosmetic emulsifier mixers are another vital category. They combine ingredients that typically do not mix easily, such as oils and water, to form stable emulsions. The cosmetic vacuum emulsifying machine enhances this process by using vacuum technology to ensure that no air pockets are present, which helps in achieving a smooth and stable product.

Whether you're working with small-scale batches or large commercial productions, the right homogenizer and emulsifier are crucial for achieving the desired quality and consistency in cosmetic products. From the cosmetic homogenizer and homogenizer for cosmetics to the industrial mixer homogenizer and cosmetic vacuum emulsifying machine, each type of equipment plays a specific role in the formulation process. Investing in high-quality equipment ensures that your cosmetic products meet industry standards and deliver exceptional performance.

By integrating these advanced machines into your production line, you can ensure that your products maintain a consistent texture, quality, and efficacy, ultimately enhancing customer satisfaction and achieving success in the competitive cosmetics market.

Enhance Product Quality and Efficiency with a Cosmetic Homogenizer

In the competitive world of cosmetics manufacturing, the need for efficient and high-quality production processes is paramount. One essential tool that plays a significant role in achieving product consistency and stability is the cosmetic homogenizer. This article explores the features, benefits, and applications of cosmetic homogenizers, highlighting their importance in the cosmetics industry.

Cosmetic Homogenizer for Sale:

Finding the right cosmetic homogenizer for your manufacturing needs is crucial. With a wide range of options available, selecting a reliable and efficient homogenizer ensures consistent product quality. Whether you require a lab-scale homogenizer or an industrial-grade machine, exploring the market for the best cosmetic homogenizer for sale will help you make an informed decision.

Cosmetic Homogenizer Mixer:

Combining homogenization and mixing capabilities, the cosmetic homogenizer mixer is a versatile tool for cosmetics manufacturers. This equipment allows for efficient blending of various ingredients, resulting in a homogeneous mixture with uniform particle distribution. The cosmetic homogenizer mixer is designed to meet the specific requirements of cosmetic formulations, ensuring optimal texture, stability, and appearance of the final product.

Homogenizer for Cosmetics:

The homogenizer for cosmetics is a specialized device that effectively disperses, emulsifies, and homogenizes cosmetic ingredients. It ensures the uniform distribution of particles, eliminates agglomerates, and reduces the size of droplets, resulting in smooth and consistent formulations. This process significantly improves product quality, shelf life, and customer satisfaction.

Homogenizer Mixer for Cosmetics:

The homogenizer mixer for cosmetics combines the functions of a homogenizer and a mixer, providing manufacturers with a comprehensive solution. This versatile equipment enables simultaneous blending and homogenization, reducing production time and improving efficiency. By incorporating a homogenizer mixer into your cosmetic manufacturing process, you can achieve superior product consistency and stability.

Homogenizer Mixer Machine:

The homogenizer mixer machine is an advanced piece of equipment designed for large-scale cosmetic production. This industrial-grade machine offers high-speed blending and homogenization capabilities, capable of handling large volumes of ingredients. With customizable settings and user-friendly controls, the homogenizer mixer machine provides precise control over the production process, resulting in consistent and high-quality cosmetic products.

Industrial Mixer Homogenizer:

The industrial mixer homogenizer is a powerful tool used in the cosmetics industry for large-scale manufacturing. With its robust design and high-speed operation, it effectively combines, emulsifies, and disperses ingredients. This equipment is suitable for a variety of cosmetic applications, including the production of lotions, creams, gels, and other emulsion-based formulations.

Lab Mixer Homogenizer:

In research and development laboratories, a lab mixer homogenizer is an essential tool for small-scale formulation testing. This compact and efficient equipment allows scientists and cosmetic formulators to evaluate and optimize various formulas. The lab mixer homogenizer provides valuable insights into the behavior and performance of cosmetic ingredients, facilitating the creation of innovative and high-quality products.

Lotion Homogenizer:

Creating smooth and consistent lotions requires precise emulsification and homogenization. The lotion homogenizer is specifically designed to handle the unique challenges of lotion production, ensuring uniform distribution of ingredients and preventing phase separation. By utilizing a lotion homogenizer, manufacturers can achieve excellent product stability and appearance, resulting in luxurious and satisfying skincare experiences.

Mayonnaise Homogenizer:

Beyond cosmetics, the homogenizer finds application in the food industry as well. The mayonnaise homogenizer plays a vital role in achieving the desired texture and stability of mayonnaise products. This equipment disperses and blends oil, eggs, and other ingredients, resulting in a smooth and creamy emulsion. By incorporating a mayonnaise homogenizer into the manufacturing process, food producers can consistently deliver high-quality and delicious mayonnaise products.

Conclusion

The cosmetic homogenizer is an indispensable tool for cosmetics manufacturers seeking to improve product quality, stability, and efficiency. Whether you require a lab-scale mixer or an industrial-grade machine, selecting the right cosmetic homogenizer for sale ensures uniform particle distribution, improved texture, and customer satisfaction. Embracing this advanced technology empowers manufacturers to stay ahead in the competitive cosmetics industry.