Mic Machinery Perfume Filling Packing Machine

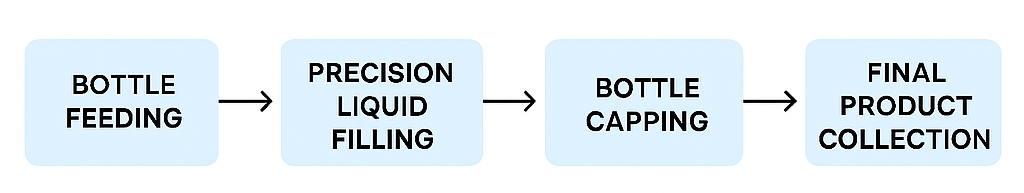

Perfume Packaging Machine power supply is 220V 50Hz, And Air Supply is 1.3 m3/h 0.4-0.8Mpa. When machine sensor bottle come into the turntable, then fill perfume into bottles. The machine process is bottle loading-bottle filling- bottle capping.

Machine Speed: 20-30 BPM

MIC Semi Automatic Perfume Filling Machine

Semi Automatic Perfume Filling Machine can fill 10-100ml perfume bottles. This machine speed is 20-30 bottles per minute. Machine uses negative pressure vacuum filling. It can keep the product level relatively consistent.

Machine Speed: 20-30 BPM

How does the perfume filling line work?

Auxiliary Equipment

Perfume Filling Production Line

Advantages

● High Precision and Consistency: Accurate filling without overflow or leakage, ideal for premium fragrances.

● Flexible Configuration: Suitable for various bottle shapes, sizes, and cap types.

● Hygienic and Clean Operation: Made with stainless steel and anti-corrosive materials, complying with cosmetic standards.

● Easy Maintenance and Operation: User-friendly interface with minimal technical training required.

Main Functions

● Automatic Bottle Feeding: Aligns and delivers bottles into the system.

● Perfume Filling: Uses vacuum or piston filling technology to ensure accurate dosing.

● Bottle Capping: Automatically seals bottles with spray pumps or screw caps.

● Labeling: Applies self-adhesive labels with precise positioning.

● Date Coding (Optional): Prints batch numbers or expiration dates.

● Finished Product Collection: Moves completed bottles to the packing area.

Integrated Automation for Streamlined Packaging

Our production line includes integrated modules for bottle feeding, perfume filling, cap insertion, bottle capping, and automatic labeling. Each section is synchronized via a PLC control system and touch screen interface, allowing operators to adjust parameters easily. This automation greatly reduces labor costs and enhances production speed without compromising quality.

Mic Machinery: Customization and Innovation

As a leading perfume filling line manufacturer, Mic Machinery provides fully customizable solutions tailored to your specific packaging needs. From bottle and label design to nozzle selection and output capacity, we adapt every component of the line to match your brand’s aesthetic and efficiency targets. Our R&D team is also available to support product upgrades and new project development.

Stable Performance & Global Service

The entire line is built with food- and cosmetic-grade stainless steel, featuring corrosion-resistant and easy-to-clean materials that meet international standards. With installations in over 60 countries, Mic Machinery offers global technical support, installation guidance, and long-term maintenance service, ensuring reliable performance and peace of mind.

Why Choose Mic Machinery for Perfume Filling?

☑ Over 15 years of expertise in filling & packaging equipment

☑ Strong customization capabilities

☑ High-speed, low-waste filling technology☑ Smart control system with safety alarms

☑ Competitive pricing and fast delivery

☑ Multilingual support and global shipping

Semi Automatic Perfume Filling Machine can fill 10-100ml perfume bottles. This machine speed is 20-30 bottles per minute. Machine uses negative pressure vacuum filling. It can keep the product level relatively consistent.

Perfume Bottle Filling Machine use the PLC to control the machine, the operation is more convenient and flexible. The machine is made of stainless steel, which not only looks neat and beautiful, but also meets the production standards.

Perfume Packaging Machine power supply is 220V 50Hz, And Air Supply is 1.3 m3/h 0.4-0.8Mpa. When machine sensor bottle come into the turntable, then fill perfume into bottles. The machine process is bottle loading-bottle filling- bottle capping.

Manual Perfume Filling Machine Has 4-6 filling head. This machine can fill 5-1000 perfume bottles. Speed is 40-60 bottles per minute. And this machine also can fill floral water, perfume and other water-based materials.

Mic Double Side Adhesive Labeling Machine

Double Side Adhesive Labeling Machine speed is 120-250 vials/min (adjustable speed, depending on object size and label length). Operation process: product placement (line connection) -- > product delivery -- > product separation -- > labeling (automatic realization of equipment) -- > collection of labeled products.

MIC Single-Sided Adhesive Labeling Application Machines

Single-Sided Adhesive Labeling Application Machines labeling speed is 80-220 vials/min (adjustable speed, depending on object size and label length). Machine can realize single-side and double-side labeling of four products (round bottle, flat bottle, square bottle and special-shaped bottle).

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System

- Blowing Filling Capping Machine

- Barrel Filling Line