Comprehensive Guide to Bottle Filling Machines: Types, Performance, and Pricing

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

Automatic Bottle Filling Machine

An automatic bottle filling machine is designed for high-speed production lines where precision and speed are paramount. These machines are fully automated, requiring minimal human intervention, and are ideal for large-scale operations. They ensure consistent fill levels, reduce waste, and increase overall efficiency.

Semi Auto Bottle Filling Machine

A semi-auto bottle filling machine offers a balance between automation and manual control. While some processes are automated, operators may still need to manage certain aspects, such as bottle placement or start/stop functions. This type of machine is suitable for medium-scale operations where flexibility and control are required.

Fully Automatic Bottle Filling Machine

The fully automatic bottle filling machine represents the pinnacle of automation in the filling process. These machines are equipped with advanced features like sensors, programmable logic controllers (PLCs), and touchscreen interfaces, enabling complete automation of the filling process. They are ideal for large-scale production environments that demand high efficiency and precision.

Auto Bottle Filling Machine

Similar to the fully automatic version, an auto bottle filling machine streamlines the filling process by automating tasks such as bottle feeding, filling, and capping. These machines are essential for industries that require high throughput and minimal downtime.

Manual Bottle Filling Machine

A manual bottle filling machine requires operators to manually control the filling process. These machines are typically used in small-scale operations or for products that require precise filling, such as specialty or small-batch products. The manual bottle filling machine price is generally lower than that of automated models, making it an affordable option for startups or low-volume production.

PET Bottle Filling Machine

The PET bottle filling machine is specifically designed for filling PET (polyethylene terephthalate) bottles, which are commonly used in the beverage industry. These machines are optimized for handling the unique properties of PET bottles, ensuring that they are filled efficiently without compromising their structural integrity.

Plastic Bottle Filling Machine

A plastic bottle filling machine is versatile and can handle various types of plastic bottles, including PET, HDPE, and LDPE. These machines are widely used in the food, beverage, and personal care industries, where plastic bottles are the preferred packaging material.

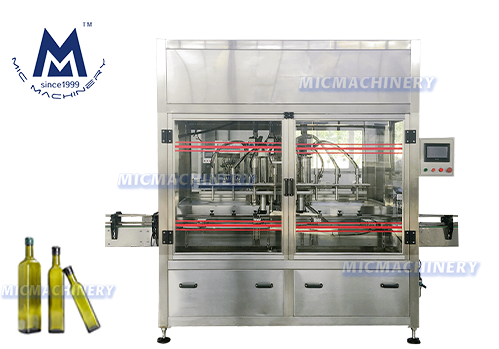

Glass Bottle Filling Machine

The glass bottle filling machine is engineered to handle the delicate nature of glass bottles, which require careful handling to avoid breakage. These machines are commonly used in the wine, spirits, and pharmaceutical industries, where glass packaging is preferred for its barrier properties and aesthetic appeal.

Automatic Bottle Filling Machine Price

The automatic bottle filling machine price can vary significantly based on factors such as capacity, features, and brand. High-end machines with advanced automation features will typically command a higher price, but they offer the benefit of increased efficiency and reduced labor costs over time.

Bottle Filling Machine Price

The overall bottle filling machine price is influenced by the machine type (manual, semi-auto, fully automatic), the materials it handles (plastic, PET, glass), and the specific industry requirements. It's essential to consider the long-term benefits of investing in a higher-priced machine, such as improved productivity and reduced operational costs.

Bottle Filling Machine for Sale

When looking for a bottle filling machine for sale, it's important to evaluate various suppliers and manufacturers to ensure you find the best machine for your needs. Consider factors like after-sales support, warranty, and customization options to make an informed purchase.

Bottle Filling Machine Manufacturer

Choosing a reputable bottle filling machine manufacturer is crucial for ensuring the quality and reliability of your equipment. Manufacturers with a strong track record in the industry often offer better support, longer warranties, and more durable machines, which can be a significant advantage in a competitive market.

Conclusion

Whether you’re operating a small-scale artisanal production or a large industrial facility, selecting the right bottle filling machine is essential for optimizing your production process. From manual bottle filling machines to fully automatic bottle filling machines, each type offers unique benefits tailored to specific operational needs. By understanding the different types, features, and pricing factors, you can choose the most suitable machine to enhance your production line's efficiency and output.