Automated Packing Machine Solutions for Industrial Efficiency

Micmachinery offers a comprehensive range of high-performance packing machines designed to improve packaging speed, accuracy, and consistency across various industries. From liquids and powders to cartons, boxes, and pallets, our machines automate every step of your packaging line, reducing labor costs and enhancing productivity.

Whether you’re in the food, beverage, pharmaceutical, chemical, or logistics industry, our packing solutions integrate seamlessly with upstream filling systems and downstream logistics to create a complete, efficient packaging workflow.

Whether you’re in the food, beverage, pharmaceutical, chemical, or logistics industry, our packing solutions integrate seamlessly with upstream filling systems and downstream logistics to create a complete, efficient packaging workflow.

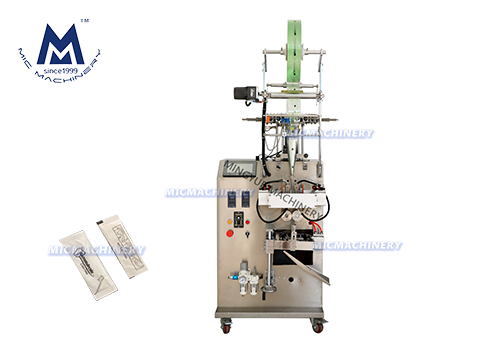

Liquid Packing Machine

Our liquid packing machine is ideal for packaging water, juices, milk, oils, and other free-flowing liquids into pouches or sachets. Using vertical form-fill-seal (VFFS) technology, it forms the package, fills it with liquid, and seals it in one continuous process.

Key Features:

● High-speed pouch forming and sealing

● Leak-proof liquid dosing with precision filling heads

Our liquid packing machine is ideal for packaging water, juices, milk, oils, and other free-flowing liquids into pouches or sachets. Using vertical form-fill-seal (VFFS) technology, it forms the package, fills it with liquid, and seals it in one continuous process.

Key Features:

● High-speed pouch forming and sealing

● Leak-proof liquid dosing with precision filling heads

● Suitable for single-serve or bulk-format flexible packaging

Food Packing Machine

The food packing machine from Micmachinery is built to handle dry food items such as snacks, grains, frozen foods, and ready-to-eat meals. The system supports both flexible and rigid packaging types, with options for MAP (Modified Atmosphere Packaging) and vacuum sealing.

Key Features:

● Hygienic stainless steel design compliant with food safety standards

● Compatible with pillow bags, trays, pouches, and clamshells

The food packing machine from Micmachinery is built to handle dry food items such as snacks, grains, frozen foods, and ready-to-eat meals. The system supports both flexible and rigid packaging types, with options for MAP (Modified Atmosphere Packaging) and vacuum sealing.

Key Features:

● Hygienic stainless steel design compliant with food safety standards

● Compatible with pillow bags, trays, pouches, and clamshells

● Supports integration with multi-head weighers and conveyors

Tea Packing Machine

Our tea packing machine is tailored for loose tea, herbal blends, or powdery leaves. It can create pyramid bags, double-chamber bags, or sealed sachets with string and tag, ensuring freshness and aesthetic appeal.

Key Features:

● Ultrasonic sealing for airtight tea bags

● Automatic tag and thread attachment

● Precise volumetric dosing for consistent portioning

Our tea packing machine is tailored for loose tea, herbal blends, or powdery leaves. It can create pyramid bags, double-chamber bags, or sealed sachets with string and tag, ensuring freshness and aesthetic appeal.

Key Features:

● Ultrasonic sealing for airtight tea bags

● Automatic tag and thread attachment

● Precise volumetric dosing for consistent portioning

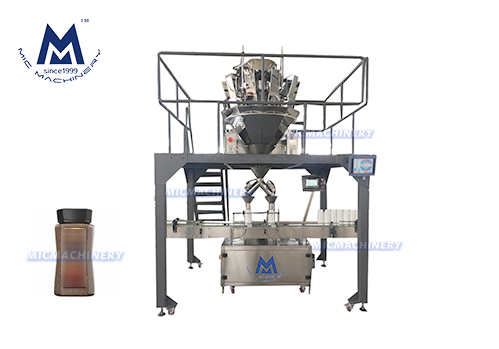

Powder Packing Machine

The powder packing machine is engineered for fine and granulated powders such as spices, coffee, flour, and pharmaceutical powders. Using auger or screw filling technology, it ensures accurate weight and mess-free operation.

Key Features:

● Dust-proof design with anti-static materials

● Suitable for stick packs, pillow pouches, or jars

The powder packing machine is engineered for fine and granulated powders such as spices, coffee, flour, and pharmaceutical powders. Using auger or screw filling technology, it ensures accurate weight and mess-free operation.

Key Features:

● Dust-proof design with anti-static materials

● Suitable for stick packs, pillow pouches, or jars

● Servo-driven filling systems for precise control

Palletizer

Micmachinery’s palletizer automates the stacking of boxes, bags, or containers onto pallets, reducing manual labor and increasing stacking precision. It is ideal for high-speed production lines and integrates with conveyors and wrapping systems.

Key Features:

● Robotic or layer-type palletizing options

● Customizable patterns and multi-line compatibility

Micmachinery’s palletizer automates the stacking of boxes, bags, or containers onto pallets, reducing manual labor and increasing stacking precision. It is ideal for high-speed production lines and integrates with conveyors and wrapping systems.

Key Features:

● Robotic or layer-type palletizing options

● Customizable patterns and multi-line compatibility

● Safety sensors and compact footprint for factory environments

Pallet Wrapping Machine

Our pallet wrapping machine secures stacked goods with stretch film, providing stability during storage and transport. Designed for speed and consistency, it ensures uniform wrap tension and film usage efficiency.

Key Features:

● Turntable, rotary arm, or ring-type configurations

● Adjustable film tension and wrapping cycles

Our pallet wrapping machine secures stacked goods with stretch film, providing stability during storage and transport. Designed for speed and consistency, it ensures uniform wrap tension and film usage efficiency.

Key Features:

● Turntable, rotary arm, or ring-type configurations

● Adjustable film tension and wrapping cycles

● Ideal for fragile, irregular, or heavy loads

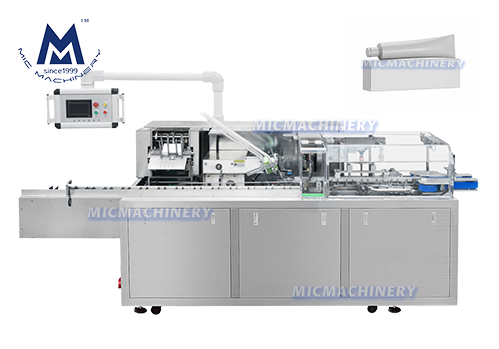

Cartoning Machine

The cartoning machine is used for packing products into pre-formed cartons. It handles everything from food and pharmaceuticals to cosmetics and hardware, with options for both horizontal and vertical cartoning.

Key Features:

● Automatic product insertion and carton sealing

● Supports tuck-in, glue, or lock-tab closures

The cartoning machine is used for packing products into pre-formed cartons. It handles everything from food and pharmaceuticals to cosmetics and hardware, with options for both horizontal and vertical cartoning.

Key Features:

● Automatic product insertion and carton sealing

● Supports tuck-in, glue, or lock-tab closures

● Integration-ready with filling and labeling lines

Wrap Packing Machine

Our wrap packing machine wraps individual or bundled products in film or paper. Ideal for bakery items, soap, hardware, and more, it provides fast, uniform packaging with minimal material waste.

Key Features:

● Supports BOPP, PVC, and biodegradable film

● Clean sealing and cutting with minimal changeover time

Our wrap packing machine wraps individual or bundled products in film or paper. Ideal for bakery items, soap, hardware, and more, it provides fast, uniform packaging with minimal material waste.

Key Features:

● Supports BOPP, PVC, and biodegradable film

● Clean sealing and cutting with minimal changeover time

● Compatible with both manual and automatic loading

Box Packer Machine

The box packer machine automates the insertion of products into outer cartons or boxes. It’s ideal for high-volume operations needing precision and consistency in box filling.

Key Features:

● Adjustable for various box sizes and product types

● Servo-controlled pushers and sensors for alignment

The box packer machine automates the insertion of products into outer cartons or boxes. It’s ideal for high-volume operations needing precision and consistency in box filling.

Key Features:

● Adjustable for various box sizes and product types

● Servo-controlled pushers and sensors for alignment

● High-speed operation with minimal downtime

Depalletizer

Micmachinery’s depalletizer efficiently unloads products from pallets and transfers them to conveyors for processing or packaging. Suitable for bottles, cans, cartons, or sacks, it reduces manual handling and improves line efficiency.

Key Features:

● Low-level and high-level depalletizing options

● Automatic layer separation and product feeding

Micmachinery’s depalletizer efficiently unloads products from pallets and transfers them to conveyors for processing or packaging. Suitable for bottles, cans, cartons, or sacks, it reduces manual handling and improves line efficiency.

Key Features:

● Low-level and high-level depalletizing options

● Automatic layer separation and product feeding

● Integrated safety doors and operator interfaces

Weight Detector

The weight detector ensures that each package meets the required weight specifications. It can reject underfilled or overfilled packages automatically, helping meet quality control standards.

Key Features:

● High-precision load cell weighing

● Real-time data tracking and reject systems

The weight detector ensures that each package meets the required weight specifications. It can reject underfilled or overfilled packages automatically, helping meet quality control standards.

Key Features:

● High-precision load cell weighing

● Real-time data tracking and reject systems

● Stainless steel hygienic design for food-grade applications

Metal Detector for Food Industry

Our metal detector for the food industry ensures that packaged food products are free from metal contamination. It is a vital part of HACCP and food safety compliance, protecting both consumers and your brand.

Key Features:

● Detects ferrous, non-ferrous, and stainless steel particles

● Auto-rejection of contaminated products

● Easy-to-clean design with IP-rated protection

Our metal detector for the food industry ensures that packaged food products are free from metal contamination. It is a vital part of HACCP and food safety compliance, protecting both consumers and your brand.

Key Features:

● Detects ferrous, non-ferrous, and stainless steel particles

● Auto-rejection of contaminated products

● Easy-to-clean design with IP-rated protection

Why Choose Micmachinery for Packing Solutions?

Micmachinery is a trusted manufacturer of packing machines that combine efficiency, accuracy, and flexibility. Our machines are tailored to your specific product, packaging format, and production volume—whether you're handling powders, liquids, solids, or full pallets.

● Turnkey packaging solutions from filling to palletizing

● Custom-built machinery for your specific application

● Global support and service for long-term productivity

Micmachinery is a trusted manufacturer of packing machines that combine efficiency, accuracy, and flexibility. Our machines are tailored to your specific product, packaging format, and production volume—whether you're handling powders, liquids, solids, or full pallets.

● Turnkey packaging solutions from filling to palletizing

● Custom-built machinery for your specific application

● Global support and service for long-term productivity

Get in Touch with Micmachinery

Looking for a reliable packing machine manufacturer to streamline your production line? Contact Micmachinery today for tailored solutions in liquid packing, powder packing, palletizing, metal detection, and more. Let us help you optimize your packaging process with precision and speed.

Looking for a reliable packing machine manufacturer to streamline your production line? Contact Micmachinery today for tailored solutions in liquid packing, powder packing, palletizing, metal detection, and more. Let us help you optimize your packaging process with precision and speed.