In-Depth Guide to Tube Packing Machines by Mic Machinery

At Mic Machinery, we understand the importance of efficiency, precision, and quality in packaging. Whether you’re producing pharmaceutical ointments, cosmetic creams, or food pastes, a Tube Packing Machine is essential for maintaining consistent quality and speeding up production. This guide will give you a comprehensive understanding of tube packing machines—what they are, how they work, their features, advantages, application areas, and how to choose the right one for your business.

|

Model |

|||||||

|

Filling Volume Range |

20-70ml |

5-75ml |

5-75ml/75-150ml/150-300ml |

2-30ml/5-75ml/75-150ml |

3-30ml/30-75ml/75-150ml |

3-30ml |

- |

|

Production Speed |

20-30 tubes/min |

30-35 tubes/min |

30-65 tubes/min |

10-50 tubes/min |

30-75 tubes/min |

60-80 tubes/min |

50-60 cartons/min |

|

Power |

4.5Kw |

4Kw |

5.5Kw |

1.1Kw |

2.2Kw |

2.2Kw |

1.5Kw |

|

Air Pressure |

0.6-0.8Mpa |

0.60MPa |

- |

0.6-0.7Mpa |

- |

- |

0.6Mpa |

|

Weight |

250 kg |

475 kg |

850 kg |

250 kg |

850 kg |

850 kg |

1300 kg |

|

Dimension (L×W×H) |

1300×700×1400mm |

1450×1050×1750mm |

1850×950×1980mm |

1130×750×1680mm |

1950×800×1850mm |

1950×800×1850mm |

3600×1200×1750mm |

|

Suitable Filling Material |

plastic tube |

plastic tube |

plastic tube |

Aluminum tube |

Aluminum tube |

Aluminum tube |

- |

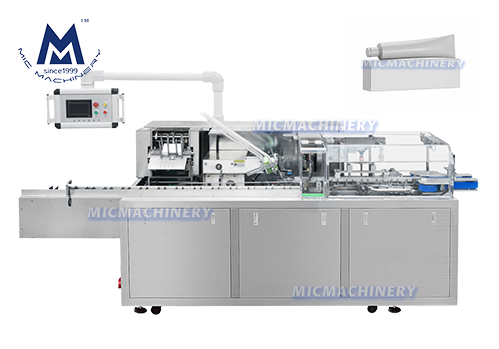

What Is a Tube Packing Machine?

A Tube Packing Machine, also known as a tube filling and sealing machine, is used to package various types of viscous and semi-viscous products into pre-formed tubes. These tubes can be made of plastic, laminated, or aluminum, depending on product requirements and branding preferences.

Tube packing machines are widely used in cosmetic, pharmaceutical, food, chemical, and adhesive industries, offering a hygienic, efficient, and visually appealing way to pack products like creams, gels, ointments, sauces, pastes, and glue.

At Mic Machinery, we specialize in automatic and semi-automatic tube packing machines designed with robust technology, ensuring superior sealing, accurate filling, and a long service life for reliable industrial performance.

Our tube packing machines are built with precision-engineered components and adhere to international standards such as GMP and CE, ensuring they meet the strict quality and hygiene requirements of sensitive industries like pharmaceuticals and cosmetics.

Here are some of the standout features and performance highlights of Mic Machinery's tube packing machines:

● Automatic Tube Feeding & Orientation: Ensures correct alignment for printed tubes, maintaining label consistency.

● Servo-Driven Filling System: Delivers highly accurate and adjustable fill volumes across a wide viscosity range.

● Advanced Sealing Options: Includes hot air sealing for plastic tubes, ultrasonic sealing for laminated tubes, and mechanical crimping for aluminum tubes.

● Touchscreen PLC Control: Provides user-friendly operation, recipe storage, and precise control over filling and sealing parameters.

● Hygienic Stainless Steel Construction: Contact parts are made of 316L stainless steel to maintain cleanliness and resist corrosion.

● Multi-Language Interface: Supports global operation with customizable language options.

● Batch Coding Integration: Includes printing or embossing options for lot numbers and expiry dates.

How to Choose the Right Tube Packing Machine?

When choosing the right tube packing machine for your production line, consider the following factors:

Different materials require different sealing mechanisms:

Plastic and laminated tubes: Use hot air or ultrasonic sealing.

Aluminum tubes: Require folding and crimping.

2. Tube Size and Volume

Mic Machinery offers machines that accommodate a wide range of tube diameters and fill volumes. Be sure to match the machine’s specifications with your product’s requirements.

3. Production Speed

Estimate your daily or hourly output needs. We offer machines with various production speeds to suit both small-batch manufacturers and high-capacity factories.

4. Product Type and Viscosity

Select a machine with suitable pump types and filling nozzles based on your product’s viscosity (cream, gel, paste, etc.).

5. Automation Level

Semi-Automatic Machines: Ideal for startups, labs, or limited-scale production.

Fully Automatic Machines: Designed for large-scale, continuous operations where speed and consistency are critical.

6. Customization and Future Scalability

Our engineers can provide tailor-made solutions including multiple filling heads, different sealing systems, or integration with existing packaging lines. Choose a machine that supports your growth plan.

With years of experience in manufacturing filling and packaging machinery, Mic Machinery has established a solid reputation in the global market. Our tube packing machines are:

● Reliable and precise, built with the latest engineering technology.

● Backed by expert support, including remote troubleshooting and on-site installation.

● Competitively priced, with strong ROI for businesses of all sizes.

● Exported globally, serving customers across Asia, Europe, the Americas, and the Middle East.

Our commitment to innovation, customization, and customer satisfaction sets us apart. When you choose Mic Machinery, you're not just buying a machine—you're gaining a long-term partner in your manufacturing success.

Conclusion

A Tube Packing Machine is a vital piece of equipment for industries requiring consistent, high-quality packaging of viscous products. From pharmaceutical ointments to cosmetic creams and food sauces, these machines ensure efficient production and a professional finish.

Contact us today to learn more about our tube packing machines and how we can help streamline your packaging operations.

If you're in the cosmetics, pharmaceutical, or personal care industry and searching for efficient and precise tube packaging solutions, you've come to the right place. At [Micmachinery], we specialize in providing cutting-edge Tube Packaging Machines designed to streamline your production process. Our state-of-the-art equipment ensures accuracy, hygiene, and exceptional results for your tube packaging needs.

Our Tube Packaging Machine is the ideal choice for automating your tube filling and sealing operations. Specifically designed to handle a wide range of products, including toothpaste, cosmetics, ointments, and more, this machine ensures precise filling and secure sealing for each tube. With its advanced technology and customizable settings, it accommodates various tube materials, offering versatility in your tube packaging process.

Whether you need a Toothpaste Packaging Machine, Tube Filling Equipment, or a complete Tube Filling Line, we have the right solution for you. Our specialized machines are engineered to meet strict industry standards, ensuring a seamless and contamination-free workflow for your cosmetic and pharmaceutical product production.

At [Micmachinery], we understand the importance of efficiency and productivity in the packaging industry. That's why our Tube Packaging Machines are designed to maximize throughput while maintaining accuracy and consistency. With their user-friendly interfaces and reliable performance, these machines minimize downtime and optimize your production line.

Invest in our advanced Tube Packaging Machines today and elevate your product packaging to new heights. Contact us now to learn more about our comprehensive solutions and how they can revolutionize your tube filling and sealing process.

One of the most common applications of tube packaging machines is in the production of toothpaste. Toothpaste packaging machines are designed to handle the specific requirements of toothpaste production, including precise filling of the tubes, sealing, and labeling. These machines are also equipped with advanced features such as automatic tube loading and unloading, filling, and capping.

Tube filling equipment is a critical component of tube packaging machines. This equipment ensures that the tubes are filled with the correct amount of product and that the filling process is efficient and consistent. Tube filling equipment includes components such as filling heads, pumps, and sensors, which work together to ensure that the tubes are accurately filled.

A tube packing machine is a complete system that includes tube filling equipment, sealing and capping equipment, and labeling equipment. This system is designed to handle the entire tube packaging process, from filling to labeling. Tube packing machines are available in different configurations, including semi-automatic and fully automatic models, to suit different production requirements.

A tube filling line is a complete production line that includes multiple tube packing machines arranged in a sequence. This line is designed to handle high-volume production requirements and is typically used in large-scale manufacturing facilities. A tube filling line includes multiple stations, each performing a specific task in the tube packaging process, such as filling, sealing, and labeling.

Finally, a tube filling system is a comprehensive solution that includes tube packaging machines, tube filling equipment, and other accessories such as conveyors and inspection systems. This system is designed to provide a complete and integrated solution for tube packaging, ensuring that the production process is efficient and of high quality. Tube filling systems are available in different configurations to suit different production requirements, including manual, semi-automatic, and fully automatic models.