Introduction to Vacuum Homogenizers and Industrial Homogenizer Mixers

|

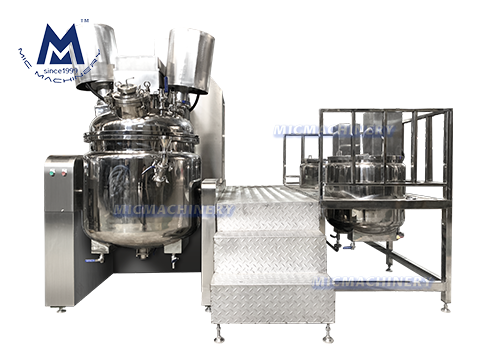

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

A vacuum homogenizer is a sophisticated piece of equipment designed to blend and homogenize products under a vacuum. This process minimizes the introduction of air and reduces oxidation, which is crucial for maintaining the integrity of sensitive ingredients. By operating under a vacuum, the homogenizer ensures a more consistent and stable product, with uniform particle sizes and improved texture. This technology is particularly advantageous in applications where maintaining the quality of delicate ingredients is paramount, such as in the production of high-end cosmetics and pharmaceuticals.

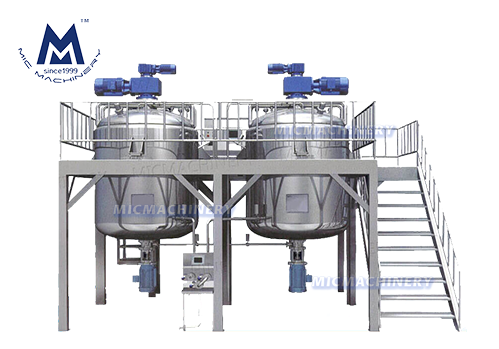

The industrial homogenizer mixer is engineered for large-scale applications, offering robust performance and efficiency in mixing and homogenizing various materials. This equipment is capable of handling significant volumes, making it ideal for production environments that require the consistent blending of large batches. The industrial homogenizer mixer operates with precision, ensuring uniformity in product texture and composition. Its design accommodates high viscosities and incorporates advanced mixing technologies to achieve the desired product characteristics, whether for food, beverages, or industrial chemicals.

Vacuum Homogenizer Cream Mixer: Optimizing Cream Production

The vacuum homogenizer cream mixer is specifically tailored for the creation of creams and lotions, blending the benefits of vacuum technology with the needs of cream production. This mixer provides precise control over the homogenization process, ensuring that creams achieve a smooth, uniform texture without the inclusion of air bubbles. The vacuum environment aids in the efficient dispersion of active ingredients, leading to high-quality, stable cream products. This type of mixer is crucial in the cosmetics industry, where the quality and consistency of cream products directly impact consumer satisfaction and product performance.

In summary, the vacuum homogenizer, industrial homogenizer mixer, and vacuum homogenizer cream mixer are essential tools for achieving high-quality results in various manufacturing processes. Each of these machines offers distinct advantages, from reducing oxidation and air inclusion to managing large-scale production and ensuring consistent cream textures. Understanding the performance and applications of these homogenizers helps industries select the right equipment to meet their specific needs, enhancing product quality and operational efficiency.

Achieve Superior Emulsification with a Vacuum Homogenizer Mixer

In the world of manufacturing, achieving efficient emulsification and homogenization processes is crucial for various industries. One powerful tool that stands out for its ability to create stable and high-quality emulsions is the vacuum homogenizer mixer. This article delves into the features, benefits, and applications of vacuum homogenizer mixers, highlighting their significance in industries that demand precision and consistency.

Vacuum Emulsifier Homogenizer:

The vacuum emulsifier homogenizer is a cutting-edge device designed to create stable emulsions and homogenize various products efficiently. By incorporating a vacuum system, this equipment eliminates air bubbles, preventing oxidation and ensuring the longevity of products. The vacuum emulsifier homogenizer is widely used in industries such as cosmetics, pharmaceuticals, food, and chemical manufacturing.

Vacuum Homogenizer Mixer Machine:

A vacuum homogenizer mixer machine is an advanced piece of equipment designed for large-scale production. This machine combines the capabilities of a homogenizer and a mixer, providing manufacturers with a comprehensive solution. By operating under vacuum conditions, this mixer machine efficiently reduces the size of particles and droplets, resulting in superior emulsions and homogeneous mixtures.

Vacuum Homogenizer Mixer:

The vacuum homogenizer mixer is a versatile tool that ensures precise and consistent emulsification and homogenization processes. This mixer combines the benefits of vacuum technology with high-speed blending, enabling manufacturers to achieve uniform particle distribution and excellent stability in their products. The vacuum homogenizer mixer is widely used in the cosmetics, pharmaceutical, and food industries for producing creams, lotions, ointments, and other emulsion-based formulations.

Vacuum Homogenizer:

A vacuum homogenizer is an essential device that operates under reduced pressure conditions, enhancing the efficiency and quality of emulsification processes. By removing air from the mixture, the vacuum homogenizer reduces the chances of oxidation and product degradation. This equipment is particularly useful in industries where the preservation of product integrity is critical, such as cosmetics, pharmaceuticals, and food manufacturing.

Vacuum Mixer Homogenizer:

The vacuum mixer homogenizer is a powerful tool used in various industries to achieve superior emulsification and homogenization. By combining vacuum technology with high-speed mixing, this equipment ensures the efficient reduction of particle sizes and uniform distribution of ingredients. The vacuum mixer homogenizer is commonly employed in applications such as the production of cosmetics, pharmaceuticals, paints, and adhesives.

Benefits of Vacuum Homogenizer Mixers:

Improved Stability: The vacuum homogenizer mixer creates stable emulsions with minimal air inclusion, enhancing product stability and shelf life.

Enhanced Texture and Appearance: By reducing particle sizes and achieving uniform distribution, vacuum homogenizer mixers result in smooth textures and appealing appearances.

Efficient Mixing and Homogenization: These mixers combine high-speed blending with vacuum conditions, ensuring rapid and efficient mixing and homogenization processes.

Product Consistency: Vacuum homogenizer mixers provide consistent results, ensuring the uniformity of product formulations batch after batch.

Reduced Oxidation: The vacuum environment minimizes the contact between the product and air, reducing oxidation and preserving the quality of sensitive ingredients.

Conclusion:

Vacuum homogenizer mixers are essential tools for industries that require precise and efficient emulsification and homogenization processes. Whether in the cosmetics, pharmaceutical, food, or chemical manufacturing sectors, these advanced machines offer numerous benefits such as improved stability, enhanced texture, and efficient mixing. By incorporating a vacuum homogenizer mixer into their production processes, manufacturers can elevate the quality and consistency of their products, ultimately enhancing customer satisfaction and market competitiveness.