Comprehensive Guide to Bottle Fillers and Bottling Equipment

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

Bottle Filler

A bottle filler is a key component in the bottling process, responsible for accurately dispensing liquid into bottles. These machines are designed to handle various types of liquids, from water and juices to more viscous products like sauces and oils. The performance of a bottle filler directly impacts the efficiency and consistency of the bottling process.

Manual Bottle Filler

A manual bottle filler is operated by hand, offering greater control over the filling process. This type of filler is ideal for small-scale production or for products that require precise, careful filling. Although manual fillers require more labor, they are cost-effective and versatile, making them suitable for niche markets and artisanal products.

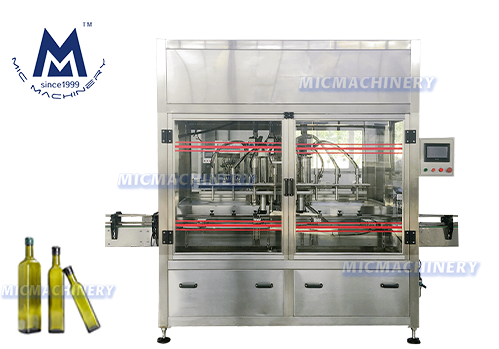

Automatic Bottle Filler

An automatic bottle filler automates the filling process, significantly increasing production speed and accuracy. These machines are equipped with advanced sensors and controls that ensure each bottle is filled to the correct level with minimal waste. Automatic bottle fillers are ideal for large-scale operations where consistency and efficiency are critical.

Glass Bottle Filler

The glass bottle filler is specifically designed to handle the delicate nature of glass bottles. These fillers are engineered to ensure that glass bottles are filled gently and accurately, minimizing the risk of breakage. This type of filler is commonly used in industries where product presentation is important, such as wine, spirits, and premium beverages.

Automatic Bottle Filler Machine

The automatic bottle filler machine represents the pinnacle of bottling technology, integrating advanced features like programmable logic controllers (PLCs), touchscreens, and automated cleaning systems. These machines are designed for high-speed production environments, offering unmatched efficiency and precision. The auto bottle filler is particularly beneficial in sectors where production volumes are high, and downtime needs to be minimized.

Bottling Equipment

Bottling equipment encompasses all the machinery used in the bottling process, including bottle fillers, cappers, labelers, and packaging machines. Investing in high-quality bottling equipment ensures smooth, efficient operations and high-quality output. The right equipment can make a significant difference in production speed, product quality, and overall operational efficiency.

Bottling Equipment for Sale

When looking for bottling equipment for sale, it’s important to evaluate the specific needs of your production line. This includes the type of product being bottled, the production volume, and the type of bottles used. High-quality equipment will offer reliability and durability, reducing the need for frequent maintenance and repairs.

Bottling Line Equipment

A complete bottling line equipment setup includes all the machinery required to take a product from raw material to finished, packaged product. This includes fillers, cappers, labelers, and conveyors. Choosing the right bottling line equipment ensures that every stage of the bottling process is optimized for speed, accuracy, and efficiency.

Bottle Filling Equipment

Bottle filling equipment is crucial for ensuring that each bottle is filled to the correct level with the desired product. Whether you are filling liquids, semi-liquids, or even powders, the right equipment will ensure consistency and precision.

Bottle Filling Equipment for Sale

When searching for bottle filling equipment for sale, it’s important to consider factors like the type of liquid being filled, production capacity, and budget. Investing in reliable and durable equipment will ensure long-term productivity and minimize operational disruptions.

Manual Bottle Filling Equipment

For small-scale operations or specialized products, manual bottle filling equipment offers flexibility and control. While these machines may not match the speed of automatic systems, they provide a cost-effective solution for lower production volumes or when precise control over the filling process is required.

Conclusion

Selecting the right bottle filler and bottling equipment is crucial for achieving efficiency, consistency, and quality in your production line. Whether you opt for a manual bottle filler for artisanal products or an automatic bottle filler machine for large-scale operations, understanding the performance characteristics of each type of equipment will help you make an informed decision. Additionally, investing in high-quality bottling line equipment ensures that every step of the bottling process is optimized, leading to higher productivity and better product quality.