Mic Machinery Silicone Filling Packing Machine

MIC Semi Automatic Silicone Cartridge Filling Machine

Semi Automatic Silicone Cartridge Filling Machine fill 20-30 cartridges per minute. This machine also can fill AB glue, silicone sealant, 502 glue, super glue and etc. It takes only one worker to operate the whole machine, saving time and effort. Filling using piston type, the roller pressure to press the material before filling.

Machine Speed: 10-30 BPM

MIC Automatic Silicone Filling Machine

Automatic Silicone Filling Machine has two filling and capping heads and can fill 40-60 tubes per minute. The machine has the detection alarm and shutdown device, once the machine failure, the alarm and automatically stop operation. The filling capacity is accurate, and the error is controlled within 0.5%.

Machine Speed: 10-75 BPM

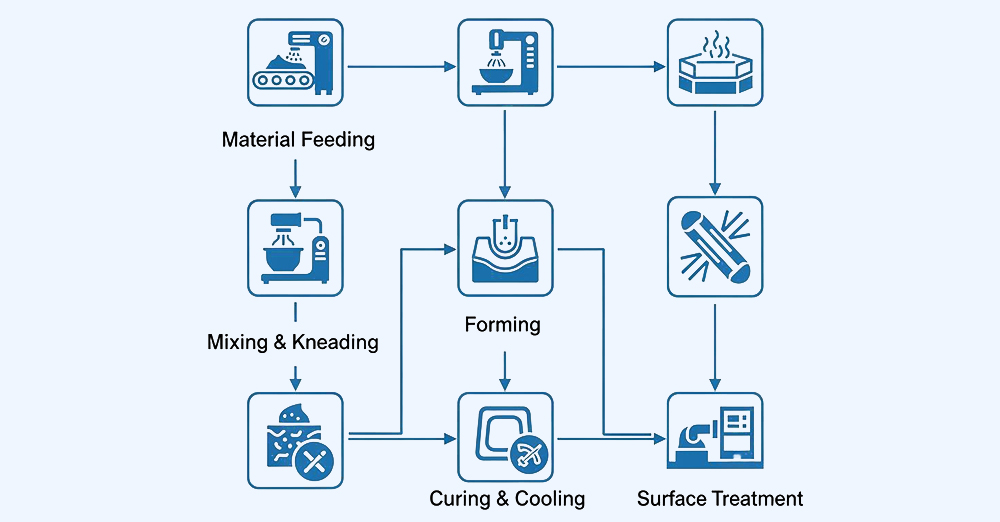

How Does the Silicone Production Line Workflow Operate?

Material Feeding: Raw silicone or silicone base compounds are loaded into the system using hoppers or vacuum loaders.

Mixing & Kneading: Materials are blended with additives, pigments, or curing agents to create a uniform mixture.

Forming: Depending on the product type, the silicone is shaped through extrusion, compression molding, or injection molding.

Curing & Cooling: Formed parts are heat-cured in ovens or tunnels, then cooled to stabilize their physical properties.

Surface Treatment: Optional steps like trimming, polishing, or anti-stick coating prepare the product for packaging.

What Are the Core Advantages of Using a Silicone Production Line?

High Automation: Reduces manual intervention, ensuring higher throughput and operational efficiency.

Consistent Quality: Real-time process monitoring and precise control over temperature and pressure maintain uniform product standards.

Cost Efficiency: Optimized material usage and reduced labor lower long-term production costs.

Scalability: The modular design allows for easy adjustments or upgrades based on output demands.

Compliance Ready: Modern systems are built to meet industry-specific standards, including food-grade or medical-grade production.

What Auxiliary Equipment Supports Silicone Manufacturing?

Why Are Labeling and Capping Machines Important in Silicone Production?

How Is the Future of Silicone Production Evolving?

Introduction to parameters of silicone filling machine

|

Model |

|||||||||

|

Filling Volume Range |

3-30ml/30-75ml/75-150ml |

3-20ml, 15-75ml, 75-250ml |

Max 310ml |

Max 600ml |

100-300ml |

280-380ml (customizable up to 400-600ml) |

200-600ml (customizable) |

100-300ml |

300-310ml |

|

Production Speed |

30-75 Tubes/min |

40-45 Tubes/min |

40-60 Cartridges/min |

10-25 Pieces/min |

10-30 Bottles/min |

15-23 Cartridges/min |

15-23 Cartridges/min |

10-30 Bottles/min |

20-30 Cartridges/min |

|

Power |

2.2Kw |

2.2Kw |

- |

- |

- |

5.5Kw |

5.5Kw |

- |

1.5Kw |

|

Air Pressure |

- |

- |

≮0.5MPa |

0.6-0.8 MPa |

0.4-0.8Mpa |

0.55Mpa-0.65Mpa |

0.55Mpa-0.65Mpa |

0.4-0.8Mpa |

0.6 Mpa |

|

Weight |

850Kg |

800 Kg |

1100Kg |

650Kg |

550kg |

700 kg |

700 kg |

550kg |

300Kg |

|

Dimension (L×W×H) |

1950×800×1850mm |

1950×800×1850mm |

5200×1450×2200mm |

1950×1150×1950mm |

1200×1000×1800mm |

1200×900×1800mm |

1200×900×1800mm |

1200×1000×1800mm |

1000×800×1650mm |

|

Suitable Container |

Aluminum Tube |

- |

¢50mm×300ML |

¢44mm/¢46mm/¢48mm |

- |

Ф10mm-Ф150mm (customizable) |

Ф10mm-Ф150mm (customizable) |

- |

300-310ml cartridge |

|

Applications |

Silicone,Ointment, Cosmetic |

Silicone,Toothpaste, AB Glue |

Silicone |

Silicone |

Silicone |

Silicone |

Silicone Sealant |

- |

PU glue, Silicone Sealant |

MIC-L60 Automatic Silicone Tube Filling Machine

Automatic Silicone Tube Filling Machine fill 30-75 tubes per minute. This machine fill aluminum tubes, filling volume can easy adjust. When the machine sensor no tube is coming, it can stop working automatically. This machine can also fill 502 glue, super glue, AB glue, gel glue and space food and etc.

MIC-L45I Silicone Tube Filling Machine

Silicone Tube Filling Machine fill 40-45 tubes per minute. The filling process does not produce noise, and the machine operates stably. The heating time can be modified according to the packing material. The cutting system will cut the tail of the tube flat.

MIC Automatic Silicone Filling Machine

Automatic Silicone Filling Machine has two filling and capping heads and can fill 40-60 tubes per minute. The machine has the detection alarm and shutdown device, once the machine failure, the alarm and automatically stop operation. The filling capacity is accurate, and the error is controlled within 0.5%.

MIC Silicone Cartridge Filling Machine

Silicone Cartridge Filling Machine fill 10-30 tubes per minute. The whole machine is operated by the control panel and presses the corresponding button. It is much more convenient and simple to operate. The filling and capping process are on the machine. And we can see the machine working very intuitively.

Semi Automatic Silicone Cartridge Filling Machine fill 20-30 cartridges per minute. This machine also can fill AB glue, silicone sealant, 502 glue, super glue and etc. It takes only one worker to operate the whole machine, saving time and effort. Filling using piston type, the roller pressure to press the material before filling.

MIC Silicone Sealant Filling Machine

Silicone Sealant Filling Machine fill 10-25 tubes per minute. This machine working flow is film feeding - shape setting - film sealing - adhesive dosing - clip locking - finished sausage cutting. The machine adopts hydraulic feeding machine, the loss of material is very small, can meet the requirements of different viscosity materials.

Silicone Filling Machine fill 10-30 bottles per minute. The whole machine is made of 304 stainless steel. Warning when the machine fails, such as no wrapping material or no cover. The machine adopts automatic pipe system, the pipe will enter the filling machine in order, more effectively save labor costs.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System

- Blowing Filling Capping Machine

- Barrel Filling Line