Introduction to Shampoo Filling and Packaging Machines

|

Model |

||||||

|

Filling Heads/Nozzles |

8 heads |

1 head |

1 head |

1 head |

1 head |

4 nozzles |

|

Filling Volume Range |

200ml-2500ml |

20-70ml |

10ml-5000ml |

10ml-5000ml |

1-100 grams |

500ml-5000ml |

|

Production Speed |

≤4000 Bph (1L bottle) |

20-30 tubes/min |

5-25 bottles/min |

1-50 bottles/min |

20-40 sachets/min |

3000-3600 BPH (1L), 1200-1800 BPH (5L) |

|

Power |

3.0Kw |

4.5Kw |

30W |

220W |

1180W |

8Kw |

|

Work Pressure |

0.55Mpa-0.65Mpa |

0.6-0.8Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

- |

0.56Mpa-0.8Mpa |

|

Size (L×W×H) |

2800×1400×2500mm |

1300×700×1400mm |

1000×480×700mm |

500×580×1380mm |

800×800×1800mm |

4000×1200×1700mm |

|

Weight |

1000 kg |

250 kg |

35 kg |

60 kg |

260 kg |

300 kg |

|

Suitable Container |

Ф40mm-Ф100mm |

35mm tube |

Bottles |

Bottles |

Sachets (L: 20-160mm, W: 20-100mm) |

Customizable |

|

Applications |

Cream, Paste, Honey,Shampoo |

Cosmetic, Ointment,Shampoo |

Liquid, Sauce, Oil,Shampoo |

Sauce, Liquid, Ketchup,Shampoo |

Honey, Shampoo, Paste |

Cream, Paste, Honey,Shampoo |

A shampoo filling machine is specifically designed for the efficient and precise filling of shampoo products into containers. These machines ensure minimal wastage, prevent spillage, and ensure that each container is filled with the exact amount of product. Key performance features include:

Accuracy: Advanced systems for precise dosing ensure uniform fills across all containers.

Adaptability: Designed to handle various shampoo viscosities, from thick to liquid formulations.

Shampoo Filling Equipment

Shampoo filling equipment refers to the machinery that encompasses the entire filling process, from product dosing to container sealing. This equipment can be used for both small-scale and large-scale production, providing flexibility and control over the filling process. Performance features include:Customizable settings: The equipment can be adjusted to fill a wide range of container types and sizes.

High-speed production: Ideal for large production lines requiring quick turnaround times.

Shampoo Packing Machine

The shampoo packing machine ensures that shampoo containers are efficiently packed for distribution. This machine often handles the filling, sealing, and labeling processes, making it a key component in the packaging line. Performance advantages include:Automation: Automatic systems streamline the packing process, reducing labor costs and improving productivity.

Versatility: Capable of handling various types of packaging, including bottles, pouches, and sachets.

Shampoo Pouch Packing Machine

The shampoo pouch packing machine is designed for packaging shampoos into pouches, which are a popular choice for travel-sized or single-use applications. This machine ensures that pouches are filled, sealed, and ready for shipment or retail. Features include:Sealing technology: Leak-proof seals that preserve product integrity.

Efficiency: High-speed production for large volumes, making it ideal for mass-market products.

Shampoo Bottle Filling Machine

A shampoo bottle filling machine is engineered to fill bottles with shampoo quickly and accurately. These machines can handle various bottle shapes and sizes and are equipped with precision nozzles for accurate filling. Key benefits include:High-speed filling: Capable of filling multiple bottles simultaneously to increase throughput.

Precision: Ensures that each bottle is filled with the correct volume of shampoo, reducing waste.

Shampoo Sachet Packing Machine

The shampoo sachet packing machine is ideal for single-use sachets, providing a cost-effective packaging solution for sample sizes or small portions. This machine is suitable for both high and low production environments. Performance advantages include:Compact design: Suitable for manufacturers with limited space.

Accurate dosing: Ensures that each sachet contains the exact amount of shampoo required.

Shampoo Packing Machine Price

The shampoo packing machine price varies depending on factors like production speed, automation level, and machine capacity. Manufacturers can choose from:Manual machines: Lower cost, suitable for small-scale operations.

Automatic machines: Higher upfront costs but more efficient for large-scale production, providing a quick return on investment.

Manual Shampoo Filling Machine

The manual shampoo filling machine is a simple, cost-effective solution for small businesses or niche product lines. It offers hands-on control over the filling process, making it ideal for custom or small-batch production. Features include:Flexibility: Allows operators to manually control the filling process, ensuring accuracy for specialized products.

Affordability: Lower cost compared to fully automatic systems, making it accessible for small manufacturers.

Shampoo Packaging Machine

The shampoo packaging machine is integral to ensuring that filled shampoo containers are sealed, labeled, and packaged correctly. This machine is often part of a larger production line and provides:

Consistent packaging quality: Ensures that every product meets the same standards of sealing and labeling.

Scalability: Can be used in both small and large production environments, depending on the machine’s capacity.

Automatic Shampoo Filling Machine

An automatic shampoo filling machine offers full automation for large-scale production lines. This machine is capable of handling high volumes of shampoo bottles or pouches with minimal human intervention. Key features include:Efficiency: Automates the filling process, ensuring quick and consistent production.

Precision: Minimizes product waste by ensuring every container is filled with the correct amount.

Shampoo Bottle Filler

A shampoo bottle filler is a specialized machine for filling shampoo into bottles of varying sizes and shapes. It is designed to accommodate the viscosity of shampoo and ensure accurate filling. Performance highlights include:Speed and accuracy: Ideal for high-speed production lines where bottle consistency is key.

Adjustability: Can be easily adjusted to accommodate different bottle types.

Shampoo Pouch Filling Machine

The shampoo pouch filling machine is a high-efficiency machine designed to fill and seal shampoo pouches. This machine is ideal for manufacturers looking to produce portable, travel-sized shampoo products. Features include:Automated pouch filling: Reduces labor and increases production speed.

Precision filling: Ensures that each pouch receives the exact product volume, maintaining quality control.

Shampoo Pouch Packing Machine Price

The shampoo pouch packing machine price can vary based on automation features, speed, and production capacity. Manufacturers should consider the following:Budget: Manual machines offer lower costs but may require more labor.

Volume: Automated machines can handle larger volumes and typically provide better long-term value for large-scale production.

Shampoo Sachet Filling Machine

The shampoo sachet filling machine is designed to fill small sachets with shampoo, perfect for single-use or promotional products. It is equipped to handle high-speed production while maintaining accurate product dispensing. Key features include:Small-scale efficiency: Ideal for producing sachets in high volumes.

Precise control: Ensures that each sachet is filled with the correct amount of product.

Conclusion

Shampoo manufacturers looking to improve their production processes can benefit greatly from investing in specialized shampoo filling machines and shampoo packing machines. Whether opting for a manual shampoo filling machine for small-batch production or an automatic shampoo filling machine for high-speed operations, these machines offer precision, efficiency, and scalability. Manufacturers should evaluate their production needs, container types, and desired output when selecting the appropriate machine for their operations.By using the right equipment, manufacturers can ensure high-quality packaging, increase productivity, and reduce waste, ultimately leading to better products and cost savings.

If you're in the cosmetics and personal care industry and seeking efficient and precise shampoo filling and packaging solutions, you've come to the right place. At [Micmachinery], we specialize in providing cutting-edge Shampoo Filling Machines designed to streamline your production process. Our state-of-the-art equipment ensures accuracy, hygiene, and exceptional results for your shampoo bottling needs.

Our Shampoo Filling Machine is the perfect choice for automating your shampoo filling operations. Specifically designed to handle the unique viscosity and fragility of shampoo, this machine ensures precise filling without compromising the quality and texture of your products. With its advanced technology and customizable settings, it accommodates various bottle sizes and types, ensuring versatility in your shampoo packaging.

For convenient shampoo packaging, our Shampoo Packaging Machine offers optimal solutions. This specialized machine is engineered to handle the entire shampoo packaging process, from filling to capping and labeling, ensuring a seamless and contamination-free workflow. With its user-friendly interface and reliable performance, this machine maximizes productivity and minimizes downtime.

At [Micmachinery], we understand the importance of meeting high-volume demands. That's why our Automatic Shampoo Filling Machine prioritizes speed and efficiency. It is designed to handle large quantities of shampoo production while ensuring consistent and reliable filling. With its automated controls and integrated measurement systems, this machine minimizes human error and maximizes throughput.

Invest in our advanced Shampoo Filling Machines today and elevate your personal care product production to new heights. Contact us now to learn more about our comprehensive solutions and how they can revolutionize your shampoo filling and packaging process.

An automatic shampoo filling machine is equipped with advanced technology and precision components to ensure accurate and consistent filling volumes. These machines can handle high-speed production and are ideal for large-scale manufacturing operations. They feature programmable controls, multiple filling heads, and can be customized to meet specific production needs.

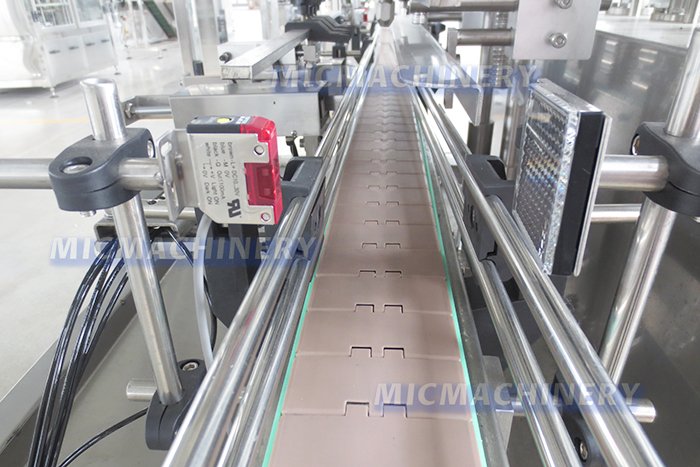

Shampoo bottle filling machines are designed specifically for the cosmetic industry and can fill a wide range of bottle sizes and shapes. They are typically equipped with conveyor systems, automatic capping machines, and labeling systems, providing a complete packaging solution for your product.

Shampoo filling equipment is available in various configurations, including inline and rotary filling machines, volumetric piston fillers, and peristaltic pumps. Each machine type has its own advantages and is suitable for different production requirements.

Overall, a shampoo filling machine is an essential piece of equipment for any cosmetic or personal care manufacturer looking to improve efficiency, reduce product waste, and increase production output.