A Comprehensive Guide to Bottle Line Machines and Bottling Solutions

|

Model |

Automatic Bottling Machine | ||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

Bottle Line Machine

A bottle line machine is the backbone of any bottling process, designed to handle the complete sequence of filling, sealing, and packaging bottles. These machines are integral to maintaining high production speeds while ensuring that each bottle is filled to the exact specifications required for the product.

Bottle Filling Line

A bottle filling line is a specialized production line that focuses on the filling aspect of the bottling process. It integrates various machines that work in unison to fill bottles accurately, minimizing spillage and ensuring consistent fill levels across all bottles. These lines are essential for operations requiring high throughput, such as beverage production.

Types of Bottling Lines

PET Bottling Line

The PET bottling line is specifically designed to handle PET (polyethylene terephthalate) bottles, commonly used in the beverage industry. These lines are optimized for speed and precision, ensuring that PET bottles are filled, capped, and labeled efficiently while maintaining the integrity of the bottle.

Bottling Line for Sale

For businesses looking to expand or upgrade their production capabilities, finding a bottling line for sale can be a cost-effective solution. These lines come in various configurations, from fully automated systems to semi-automatic setups, allowing businesses to choose the best fit for their production needs.

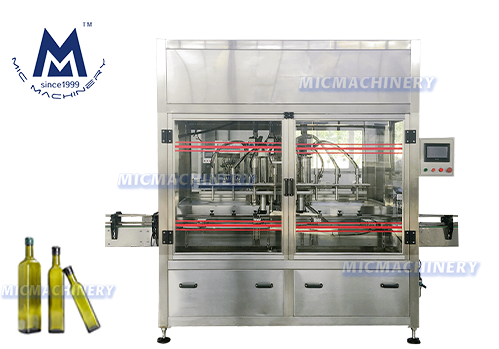

Automatic Bottling Machine

An automatic bottling machine is ideal for large-scale production environments where speed and accuracy are critical. These machines automate the entire bottling process, from filling and capping to labeling and packaging, reducing the need for manual intervention and increasing overall efficiency.

Manual Bottling Machine

For smaller operations or specialty products, a manual bottling machine offers greater control and flexibility. Operators manually handle the bottling process, which can be advantageous for low-volume production runs or when dealing with unique or delicate products.

Specialized Bottling Machines

PET Bottling Machine

The PET bottling machine is engineered to handle the specific challenges of filling PET bottles, which are lightweight and often require careful handling to avoid deformation. These machines ensure that PET bottles are filled consistently and efficiently, making them a staple in the beverage industry.

Glass Bottling Machine

The glass bottling machine is designed for the precise and careful handling required for glass bottles, which are more fragile than their plastic counterparts. These machines are often used in the production of premium beverages, such as wine and spirits, where the quality and presentation of the bottle are as important as the contents.

Pricing and Purchase Considerations

Bottling Machine Price

The bottling machine price can vary significantly based on factors such as automation level, capacity, and the type of bottles it is designed to handle. Automatic machines tend to be more expensive due to their advanced features, but they offer greater efficiency and long-term cost savings.

Bottling Machines for Sale

When looking for bottling machines for sale, it's important to consider the specific needs of your production line, including bottle type, production volume, and budget. Investing in a quality bottling machine can significantly improve your production efficiency and product consistency.

Selecting the right bottle line machine or bottle filling line is essential for ensuring efficient, high-quality production in any bottling operation. Whether you need an automatic bottling machine for large-scale production or a manual bottling machine for smaller, more controlled operations, understanding the different options and their performance characteristics will help you make an informed decision. Additionally, considering factors like bottling machine price and the specific requirements of PET or glass bottles will ensure that your investment yields optimal results in your production line.