Hot Sauce Filling Production Line

MIC Hot Sauce Filling Packing Machine

Sauce Bottle Filling machine can fill sauce, tomato sauce, chili sauce, mayonnaise. Especially can fill liquid and cream products. This machine can auto bottle loading filling and capping. The machine is highly stable and easy and easy to operate. When the machine has problems, it can automatically stop working.

Machine Speed: 5-4000 Bottles/min

Sauce bag packing machine with the automatic detection function, we can save costs for customers. When the machine fails, the machine gives an alarm. To protect the staff safe, we also made transparent shields for the machine. This machine speed is 10-50 bags per minute.

Machine Speed: 10-50 Bags/min

Hot Sauce Filling Machine Line operation flow

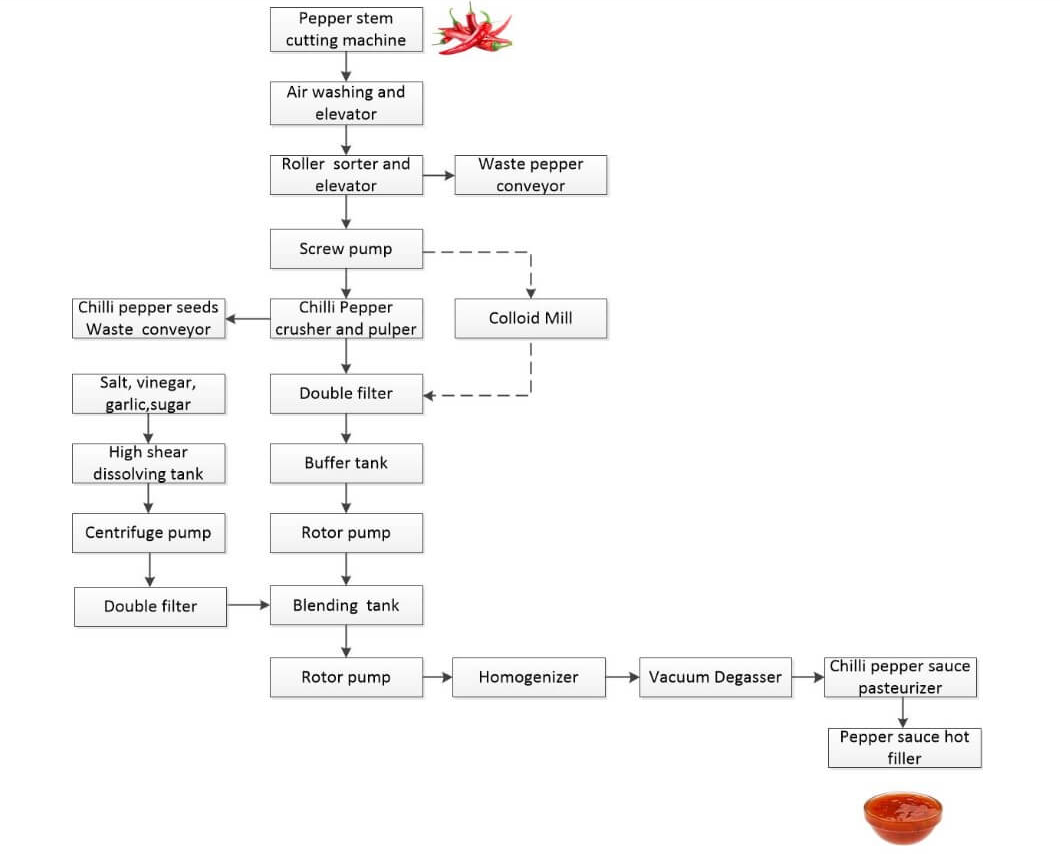

Pre preparation process:

The hot sauce production process begins with cutting and washing the peppers, followed by sorting and crushing. The mixture is then filtered, blended with ingredients like salt and vinegar, homogenized, degassed, pasteurized, and finally hot-filled into bottles.

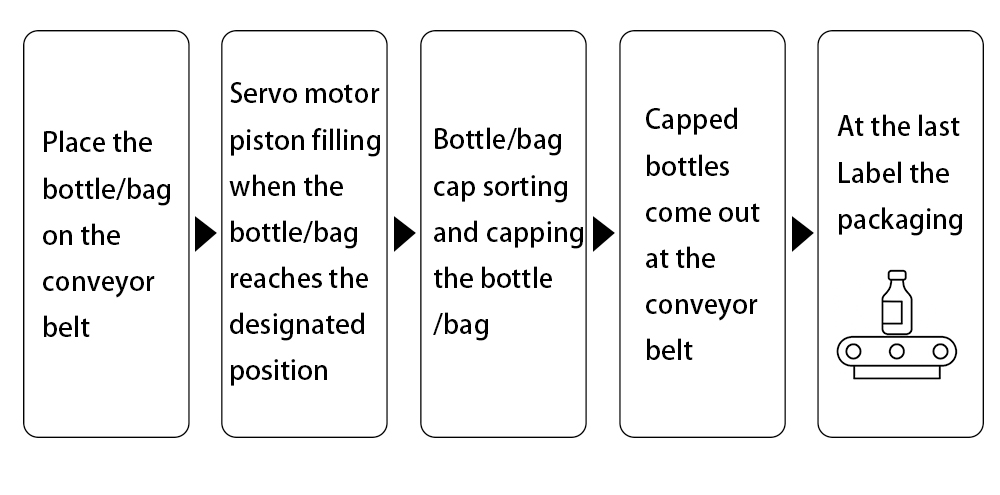

Production line operation process:

Auxiliary Equipment

The hot sauce filling production line is equipped with auxiliary machines like an automatic capping machine and a labeling machine. These ensure secure sealing and accurate label placement, enhancing product presentation and shelf readiness while improving overall production efficiency.

Advantages of a Hot Sauce Filling Production Line

High efficiency: Automates the entire bottling process, ideal for medium to large-scale production.

Hygienic handling: Built with food-grade materials to prevent contamination.

Accurate filling: Ensures each bottle has the exact volume, reducing product loss.

Labor saving: Reduces manpower needs while improving output.

Versatile container support: Works with bottles, jars, or squeeze tubes of various sizes.

Sauce Bottle Filling Equipment parameter

|

Model |

|||||||

|

Filling Heads/Nozzles |

20 heads |

5 working stations |

- |

- |

1 head |

1 head |

1 head |

|

Filling Volume Range |

200ml-2500ml |

100-500 grams (adjustable) |

- |

- |

10ml-5000ml |

10ml-5000ml |

1-100 grams |

|

Production Speed |

≤4000 Bph (1L bottle) |

30-35 cups/min |

12000 bph |

10-50 bags/min |

1-50 bottles/min |

5-25 bottles/min |

20-40 bags/min |

|

Voltage |

220V/380V |

380V/50Hz (customized) |

- |

380V 3 Phase 50Hz/60Hz |

- |

220V/380V 50/60Hz |

380V/50Hz, 220V/50-60Hz |

|

Power |

3.0Kw |

8.5Kw |

0.37Kw |

3Kw-4Kw |

220W |

30W |

1180W |

|

Work Pressure |

0.55Mpa-0.65Mpa |

0.6Mpa-0.8Mpa |

0.6MPa |

- |

0.4-0.6MPa |

0.4-0.6MPa |

- |

|

Size (L×W×H) |

2800 × 1400× 2500 |

4500×1400×1800mm |

600×800×2800mm |

- |

500×580×1380mm |

1000×480×700mm |

800×800×1800mm |

|

Weight |

1000 kg |

1600 kg |

200 kg |

1200-1500 kg |

60 kg |

35 kg |

260 kg |

|

Suitable Container |

Ф40mm-Ф100mm |

Plastic cups |

- |

Bags (W: 100-300mm, L: 100-450mm) |

Bottles |

Bottles |

Sachets (L: 20-160mm, W: 20-100mm) |

|

Applications |

Sauce, Paste, Oil |

Paste, Yogurt, Sauce |

Honey, Oil, Sauce |

Mayonnaise, Paste, Honey |

Paste, Liquid, Cosmetic |

Cosmetic, Lip balm |

Honey, Ketchup, Sauce |

Sauce Bag Packing Machine parameter

|

Model |

|||||||

|

Filling Heads/Nozzles |

20 heads |

5 working stations |

- |

- |

1 head |

1 head |

1 head |

|

Filling Volume Range |

200ml-2500ml |

100-500 grams (adjustable) |

- |

- |

10ml-5000ml |

10ml-5000ml |

1-100 grams |

|

Production Speed |

≤4000 Bph (1L bottle) |

30-35 cups/min |

12000 bph |

10-50 bags/min |

1-50 bottles/min |

5-25 bottles/min |

20-40 bags/min |

|

Voltage |

220V/380V |

380V/50Hz (customized) |

- |

380V 3 Phase 50Hz/60Hz |

- |

220V/380V 50/60Hz |

380V/50Hz, 220V/50-60Hz |

|

Power |

3.0Kw |

8.5Kw |

0.37Kw |

3Kw-4Kw |

220W |

30W |

1180W |

|

Work Pressure |

0.55Mpa-0.65Mpa |

0.6Mpa-0.8Mpa |

0.6MPa |

- |

0.4-0.6MPa |

0.4-0.6MPa |

- |

|

Size (L×W×H) |

2800 × 1400× 2500 |

4500×1400×1800mm |

600×800×2800mm |

- |

500×580×1380mm |

1000×480×700mm |

800×800×1800mm |

|

Weight |

1000 kg |

1600 kg |

200 kg |

1200-1500 kg |

60 kg |

35 kg |

260 kg |

|

Suitable Container |

Ф40mm-Ф100mm |

Plastic cups |

- |

Bags (W: 100-300mm, L: 100-450mm) |

Bottles |

Bottles |

Sachets (L: 20-160mm, W: 20-100mm) |

|

Applications |

Sauce, Paste, Oil |

Paste, Yogurt, Sauce |

Honey, Oil, Sauce |

Mayonnaise, Paste, Honey |

Paste, Liquid, Cosmetic |

Cosmetic, Lip balm |

Honey, Ketchup, Sauce |

Key Features of the System

The design of the line focuses on precision, cleanliness, and user-friendliness. Core features include:

➢ Heated mixing hopper: Maintains flow of thick or oily sauces, prevents solid settling.

➢ Piston or servo-driven filler: Offers precise volume control and anti-drip operation.

➢ Touchscreen controls (PLC): Easily adjust filling volume, speed, or container size.

➢ Automatic capping & labeling: Ensures fast and accurate finishing.

➢ Stainless steel construction: Corrosion-resistant and easy to clean (CIP compatible).

Overall Value for Manufacturers

For sauce producers, this production line adds long-term value and scalability. Benefits include:

◆ Improved product consistency: Uniform appearance and quantity boost brand image.

◆ Regulatory compliance: Meets hygiene and packaging standards across global markets.

◆ Expandable design: Optional add-ons like inkjet coders or induction sealers.

◆ Reduced downtime: Easy maintenance and reliable operation minimize stoppages.

◆ Professional packaging: Enhances shelf appeal, especially for retail-ready products.

Sacue Filling Machine can fill sauce into cups. This machine workflow is cup falling-cup detecting-cup filling-cup film sealing-cover placing and capping-discharging the finish product. This machine speed is 30-35 cups per minute. And filling volume is 100-500ml (be adjustable)

Our machine can be customized according to the size of your cup.

MIC ZF-20 Tomato Paste Filling Machine

Tomato Paste Filling Machine can fill sauce, tomato sauce, chili sauce, mayonnaise. Especially can fill liquid and cream products. This machine can auto bottle loading filling and capping. The machine is highly stable and easy and easy to operate. When the machine has problems, he can automatically stop working.

MIC ZF-12 Automatic Sauce Bottle Filling Machine

Automatic Sauce Bottle Filling Machine can fill food, cosmetics, medical and etc. The machine is plc-controlled and is very easy to use. It is filled from bottom to top. The operation can all be done on the touch screen. If the material is granular, it can also be effectively filled. And we are already at high levels in producing this machine.

Tomato Sauce Filling Machine can rinse, fill and cap pet bottles. The accessories used in this machine in the filling process are made of stainless steel material and fully meet the food requirements. The machine speed is 12000 bottles per hour and filling volume is 0-100ml.

Chili Sauce Filling Machine With the automatic detection function, we can save costs for customers. When the machine fails, the machine gives an alarm. To protect the staff safe, we also made transparent shields for the machine. This machine speed is 10-50 bags per minute.

Automatic Sauce Filling Machine can fill sauce, tomato ketchup, honey, and etc. Especially can fill cosmetic, food and chemical. If the film is finished in use, the machine stops automatically. We can encode the printed production date, valid date and other characters according to your special requirements.

Sauce Bottle Filling Machine can fill 10-5000ML. Of course, it can also be customized according to the special capacity. The machine speed is 1-50 bottles per minute. This machine is made by SUS304, with beautiful structure and very convenient operation

Hot Sauce Bottle Filling Machine can fill 10-5000ML. Of course, it can also be customized according to the special capacity. The machine speed is 5-25 bottles per minute. This machine is made by SUS304, with beautiful structure and very convenient operation.

Trigger Capping Machine can automatically locate the position of the bottle, and automatically spin the cover. The machine can be customized according to the size of the customer's bottle cap. The bottle is not twisted and scratched during the capping process. As the bottle enters and leaves the machine, we guarantee that the bottle will not get stuck in the machine.

In-Line Catch Cap Machine is highly stable and can be accurately positioned to locate the bottle. During the upper capping process, the plc control is used to retain the data. When replacing the bottle cap, you only need to replace the rotary cover head of the machine, which is more convenient to operate. The spinner is fast. And the machine parts are made of stainless steel, in line with the GMP standards.

MIC-Linear Screw And Press Capping Machine

Linear Screw And Press Capping Machine automatically sends the cap in and puts the cap right. This kind of machine is suitable for various sizes of round bottles, square bottles (barrels), flat bottles (barrels), different bottles (barrels). Speed can reach 3,000 bottles per hour.

MIC-ZF1 Automatic Press Cap Machine

Automatic Press Cap Machine the cap will be placed on the orifice in the vibration plate along the direction of the tunnel. The bottle cap presses the lid when placed on the bottle. Press the lid tightly onto the bottle. This machine can be customized to meet customer requirements. The machine is very convenient to adjust, and it is relatively easy to operate.

MIC-Linear Screw Spray Gun Cap Machine

Linear Screw Spray Gun Cap Machine suits various sizes of round bottles, square bottles (barrels), flat bottle (barrels) and shaped bottles (barrels). Machine speed is 5000 bottles per hour.The spin cover speed of the machine can be adjusted as needed.

MIC Round Bottle Labeling Machine

Round Bottle Labeling Machine after the bottle is placed on the conveyor belt, it is sent to the labeling system. The label will be removed from the drum and affixed to the bottle. The marking process is very convenient. The machine is beautiful and simple.The machine labeling speed is 50-120 vials/min (speed adjustable, depending on object size and label length)

MIC Double-Sided Adhesive Labeling Machines

Double-Sided Adhesive Labeling Machine speed is 120-250 vials/min (adjustable speed, depending on object size and label length). Operation process: product placement (line connection) -- > product delivery -- > product separation -- > labeling (automatic realization of equipment) -- > collection of labeled products.

MIC Paging Adhesive Labeling Machines

Paging Adhesive Labeling Machine labeling speed Carton labeling speed: according to carton size, please refer to the drawing for details. Bag labeling speed: 30-100 / min. The above products depend on the size of the product specification and label size. Machine Labeling accuracy is +1mm (depending on product characteristics, hardness and roundness)

Sleeve Labeling Machines Capacity(production speed) is 150 bottles per minute. The newly designed cutter stepper motor which speed is high ,action is exact,the cut is in order and the shrinking is beautiful.This design cooperate with the label synchronized location structure enable the precision of cut location within 1mm.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System

- Blowing Filling Capping Machine

- Barrel Filling Line