- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

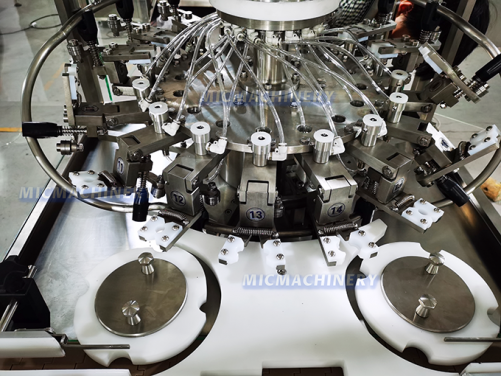

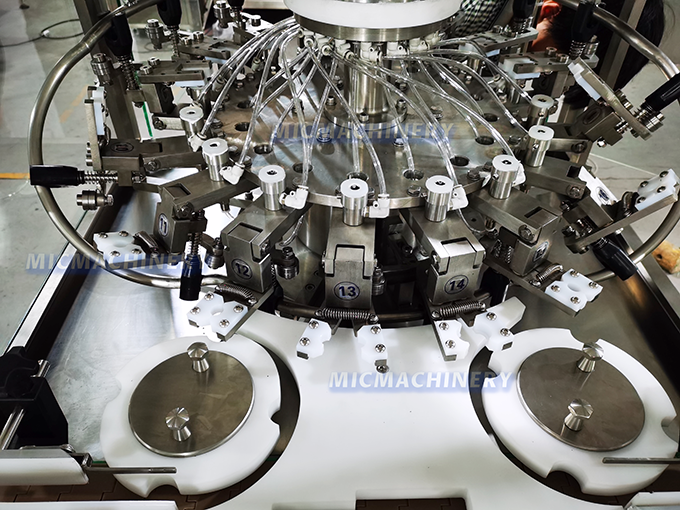

This machine is suitable for cleaning all kinds of small glass bottles. It adopts multi-head disc structure, sends the bottles to the mouth of the equating pliers through the bottle dividing mechanism, and rinses the bottles inside and outside through purified water, purified compressed air, purified water and purified compressed air for several times to complete the bottle washing. There are a variety of models to choose from. This machine is simple in structure, reliable in action, in line with GMP requirements, is the ideal equipment for pharmaceutical enterprises and health products manufacturers.

Enhanced Productivity and Workflow:

The automation and advanced features of a air washing machine contribute to increased productivity and optimized workflow. These machines are designed to handle high volumes of vials, efficiently washing 16 vials simultaneously, and maintaining a continuous flow of operation. By significantly reducing manual intervention and minimizing downtime, the washing machine enhances overall efficiency, allowing businesses to meet demanding production targets and optimize their vial preparation processes.

Seamless Integration and Process Control:

air washing machine seamlessly integrate with other production equipment and processes, creating a cohesive and efficient vial preparation line. Integration with filling machines, capping machines, and other packaging systems ensures smooth transitions between different stages of production. Furthermore, these machines feature advanced process control systems, enabling precise monitoring, adjustment, and data logging. This control enhances quality assurance, facilitates regulatory compliance, and provides real-time insights for process optimization.

A air washing machine is specifically designed to efficiently and effectively clean the interior and exterior of vials before filling. These machines automate the washing process, reducing manual labor and increasing production efficiency. The machine utilizes 16 independently functioning heads to simultaneously wash 16 vials, ensuring a rapid and sterile environment for subsequent filling processes. This efficient air washing minimizes the risk of contamination, enhances product safety, and ensures stringent quality standards.

One of the key advantages of a air washing machine is its versatility in accommodating various vial sizes and types. The machine can handle different dimensions of vials, ranging from small pharmaceutical vials to larger biotech bottles. Additionally, the machine can wash various types of vials, including clear or amber glass vials, plastic vials, and specialty vials with specific designs. This adaptability allows for flexibility in production and the ability to cater to diverse product requirements.

Consistency and reliability are vital in vial washing. A air washing machine ensures consistent washing performance by delivering thorough and uniform cleaning across all vials. The machine's 16 independent washing heads and precision controls guarantee a complete and reliable washing process for each vial, ensuring product uniformity and reliable sterilization. With reliable and consistent washing, businesses can build trust in their products and uphold stringent quality standards.