- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the sizzling universe of culinary delights, where spice meets precision, the Hot Sauce Filling Machine(Sauce Bottling Equipment) emerges as a beacon of innovation and efficiency. This cutting-edge marvel seamlessly marries the fiery essence of hot sauces with advanced automation, transforming how these zesty elixirs are bottled and delivered to kitchens and store shelves worldwide. By delving into its unique product characteristics, versatile applications, and the intricate mechanical principles guiding its operation, one can truly grasp its pivotal role in the food industry. From artisanal hot sauce makers to large-scale manufacturers and gourmet restaurants, this machine ensures that every bottle preserves the authentic heat and intensity of hot sauces, igniting culinary adventures with every drop.

Product Characteristics:

The Hot Sauce Filling Machine(Sauce Bottling Equipment) boasts an array of exceptional characteristics meticulously crafted for precision and reliability. Crafted from high-quality stainless steel and food-grade materials, these machines ensure durability, hygiene, and adherence to stringent food safety standards. Featuring specialized dosing pumps and adjustable filling nozzles, they accommodate a wide range of sauce viscosities, from mild heat to blazing intensity, catering to diverse hot sauce formulations. Equipped with advanced sensors and intuitive control panels, these machines ensure mess-free filling, minimizing wastage and optimizing resource utilization. Anti-leak features and tamper-evident seals maintain the cleanliness and freshness of the packaging, ensuring a premium end product for consumers.

Product Applications:

The applications of the Hot Sauce Filling Machine are as diverse as the sauces it encapsulates. Artisanal hot sauce makers rely on these machines to maintain the authenticity and quality of their sauces, ensuring precise portions and preserving homemade flavors. Large-scale hot sauce manufacturers utilize this equipment for bulk production, ensuring consistency, accurate portioning, and meeting the demands of both retail and food service sectors. Restaurants, fast-food chains, and gourmet eateries benefit from the precision of these machines, enhancing the presentation and portion control of their fiery dishes, meeting the high standards of chefs and diners alike. Additionally, specialty stores and online retailers leverage these machines to offer a diverse range of hot sauce varieties, from classic to exotic, providing consumers with convenient access to adventurous and spicy culinary experiences.

Mechanical Principle:

At its core, the Hot Sauce Filling Machine operates on advanced mechanical principles designed for speed, accuracy, and reliability. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of hot sauce into individual bottles. Sealing mechanisms, employing high-speed capping systems and pressure technology, secure the packaging, preserving the freshness and heat of the sauces. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of the filling and sealing operations.

In conclusion, the Hot Sauce Filling Machine embodies the epitome of culinary precision and reliability in the food packaging industry. Its exceptional product characteristics, versatile applications, and advanced mechanical principles make it an indispensable asset for hot sauce producers, culinary professionals, and retailers globally. Embracing the latest technological advancements, this machine not only ensures the accuracy of hot sauce packaging but also upholds the highest standards of flavor and consistency, enriching culinary creations and delighting spice enthusiasts. As a central element in the spicy culinary landscape, it continues to shape the way hot sauces are packaged, purchased, and savored, making it a vital component in the ever-evolving world of gastronomy and culinary arts.

Control Panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

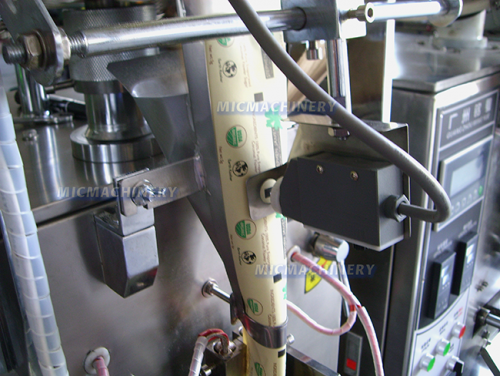

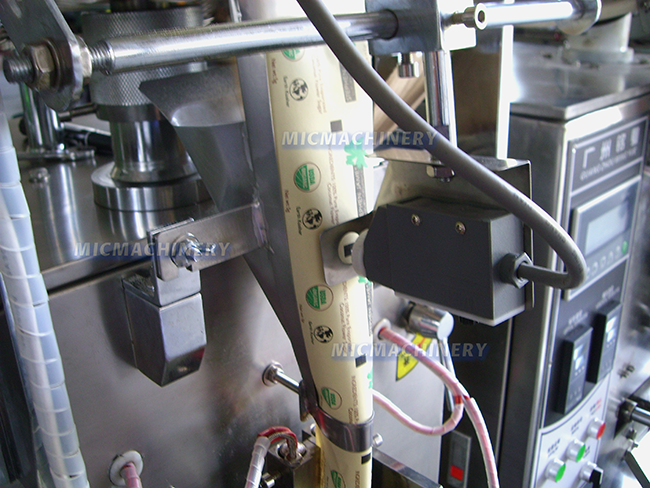

Sensor

The sensor senses the location of the film, telling the machine where to cut the bag.Photoelectric and tracing system or computer system can be provided without your specific requirements.

Bag Former

This machine can finish forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

This machine is suitable for automatic packaging of liquid of foods, medicine and chemicals,such as pesticide,shampoo,body foam bath lotion, facial cream, ingredient oil, fruit sauce,tomato ketchup and honey shower gel, skin lotion, toothpaste, cosmetic cream, fruit jam, edible oil, soy etc .

Machine features:

1. This machine can finish : forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;

2. Photoelectric and tracing system or computer system can be provided without your specific requirements.

3. The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

4. This machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

5.Eye Mark System ,machine can cut complete logo.

6.Machine Stop Automaticlly if it is out of film.

7.Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

Applicable packing film:

Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed |

5-25 B/M |

192-220 B/h (basis on 25L) |

1300-1500 B/h (basis on100ml bottle) |

≤1800 B/h ( basis on 1000ml bottle) |

3000B/h (basis on 350ml) |

3200 B /h |

≤4000 B/h (basis on1L bottle) |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.0Kw |

2.8kw |

3kw |

2.8kw |

2Kw |

3.0Kw |

|

Size |

1000*480*700 mm |

2500*1600*2500 mm |

1840*1400*2500 mm |

2000*1400*2500 mm |

1600*1400*2300 mm

|

2440*1240*2350 mm |

2800 *1400*2500 mm |

|

Weight |

35 Kg |

700 kg |

600kg |

1000kg |

3000Kg |

700 kg |

1000 kg |

In addition to,we have hot sauce bottling equipment,hot sauce bottling machine,sauce bottling equipment,sauce bottling machine,sauce bottling machine for sale.If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Capcity |

20- 40 bags/min |

|

Range of measurement |

1- 100 G |

|

Bag size |

(L) 20-160 (W) 20-100mm |

|

Sealing Type |

Back sealing |

|

Power |

1180W |

|

Total power |

380V/50HZ 220V/50-60HZ |

|

Packing material |

Paper/the polyethylene,nylon/polyethylene,tea filter paper,etc |

|

Net weight |

2 60kg |

|

Overall dimensions |

(L) 800*(W) 800*(H) 1800 |

|

Sensor |

Changtong (China) |

|

PLC Controller |

Mitsubishi/J apan |

|

Stepping motor |

Jiangsu huanyu |

|

Main Motor |

Zhaoqing Zhongbao |

|

Temperature control meter module |

Yuyao families meter |

|

Color code photoelectric |

Zhejiang both |

|

Intermediate relay |

Zhejiang both |

|

Solid state relay |

Zhaoqing Zhongbao |

|

Luck film motor |

Jiangsu huanyu . |

|

Proximity switch |

Jiangsu huanyu . |

|

Push button switch |

Japan (OMRON) |

|

Power switch |

Japan (OMRON) |

|

Color Printer for Date |

China Nanyun |

|

Machine Body |

SS202 , Material Control Parts SS304 |

- MIC-ZF20 Hot Sauce Bottling Equipment ( Sauce, Oil, Honey, 4000 Bottles/h )

- MIC Hot Sauce Packing Machine ( Sauce, Yogurt, 30-35 Cups/min )

- MIC Tracking Type Hot Sauce Filling Machine ( Chili Sauce, Oil, Paste, 3000-3600 Bottles/H )

- MIC Hot Sauce Filling Packing Machine ( Beverage, Sauce, Ketchup, 10-50 Bags/min )

- MIC Hot Sauce Bottling Machine ( Edible Oil, Sauce, 12000 Bottles/h )

- MIC Hot Sauce Filling Machine ( Ketchup, Honey, Hot Sauce, 20-40 Sachets/min )

- MIC-ZG1 Sauce Bottling Equipment ( Liquid, Honey, Cosmetic, 1-50 Bottles/min )

- MIC-V01 Sauce Bottling Machine ( Lip balm, Cosmetic, Sauce, 5-25 Bottles/min )