- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In pharmaceutical manufacturing, efficiency and precision are pivotal for ensuring the quality and timely production of medical products. The Automatic Ointment Filling Machine represents a cornerstone solution, offering automated and accurate filling for ointment containers. Let's explore its performance, focusing on its role as an ointment filling machine, automatic ointment filling machine, and ointment packaging machine.

Maximizing Performance with Automatic Ointment Filling Machine

Precision in Filling: The Automatic Ointment Filling Machine excels in precise and consistent filling of ointment containers. Equipped with advanced dosing mechanisms and controls, this machine delivers uniform filling levels, crucial for maintaining product integrity and dosage accuracy.

Efficiency through Automation: Serving as an automatic ointment filling machine, this equipment streamlines the production process by automating filling operations. Its high-speed operation and automated functionalities minimize human intervention, reduce errors, and increase production throughput, thereby optimizing efficiency.

Versatility and Adaptability: As an ointment packaging machine, the Automatic Ointment Filling Machine offers versatility and adaptability. Its modular design allows for seamless integration into existing packaging lines, accommodating various container sizes and configurations, ensuring consistent performance across diverse manufacturing needs.

Serving as an Ointment Filling Machine, Automatic Ointment Filling Machine, and Ointment Packaging Machine

Ointment Filling Machine :The Automatic Ointment Filling Machine serves as a specialized solution for automated filling of ointment containers. Its precise dosing mechanisms and automated controls ensure accurate filling, maintaining product quality and dosage integrity throughout the manufacturing process.

Automatic Ointment Filling Machine :Tailored for high-speed operation, this equipment enhances efficiency and productivity in ointment manufacturing. Its seamless integration into production lines reduces labor costs and increases overall throughput, making it a valuable asset for pharmaceutical manufacturers.

Ointment Packaging Machine: By automating the filling process, this equipment streamlines packaging operations, optimizing production efficiency. Its reliable performance and adaptable design make it suitable for a wide range of ointment packaging applications, ensuring consistent quality and compliance with regulatory standards.

Conclusion

The Automatic Ointment Filling Machine represents a significant advancement in ointment manufacturing, offering precision, efficiency, and versatility. Whether serving as an ointment filling machine, automatic ointment filling machine, or ointment packaging machine, it plays a crucial role in streamlining production processes and maintaining product quality. By investing in this advanced equipment, manufacturers can enhance efficiency, reduce costs, and ensure the timely delivery of high-quality ointment products to consumers.

This filling capping machine is suitable for:

Cosmetics, light industry (daily chemical industry), pharmaceutical, food and other industries, for enterprise products selected plastic bottles, glass bottles for packaging containers, the device can cream, ointment, cream, gel or viscous fluid.

The equipment is divided into a turntable into the bottle, automatic lift filling, automatic pre-spin cover, servo capping, a few bottles, such as the operation of the bottle into the bottle, filling the bottle, filling the bottle, and then the bottle capping operation.

1. Bottle inlet: by the artificial bottle to be filled into the hopper hopper, with the operation of the equipment in order to enhance the bottle.

2. Bottle detection: the photoelectric sensor detects whether there is an empty bottle on the main turntable, and sends the detection signal into the control computer to control the filling of the bottle, without bottle filling.

3. Filling function: If the front has detected a bottle, no bottle is not filling, PLC control filling mouth into the bottle for filling.

4. Load cover device: automatic load cover, high efficiency and more stable.

5. Capping: detection of a cover, this capping head will dive down and fix the bottle position to cap, very stable and with low noise.

6. Bottle outlet: at the last, capped bottles come out at the conveyor belt, and you can enter the next process.

Features & Benefits:

a). When the machine filling material, and use pump dedicated Teflon pipe.

b). This machine adopt plunger piston pump filling, filling volume and filling speed adjust is convenient.

c). Filling head’s assembly easy disassemble, easy cleaning, disinfection and sterilization.

d). This machine adopt lifting filling, filling head can insert the bottle, to ensure the effective filling materials.

f). Adopt the servo motor controlled screw cap, screwing cap speed and Twisting force of capping can be adjusted in touch screen directly.

J). all machine use stainless steel.

h). PLC control machine automatically,

i). With fault alarm, Mechanical overload automatic stopping device.

j). Protect cover is optional

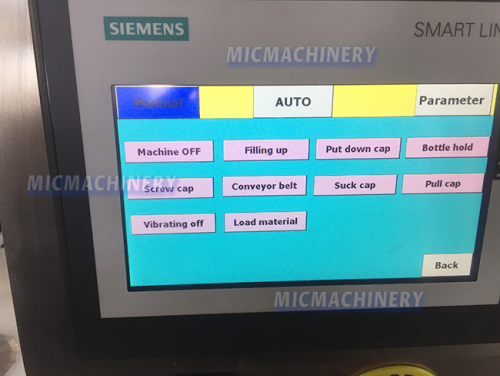

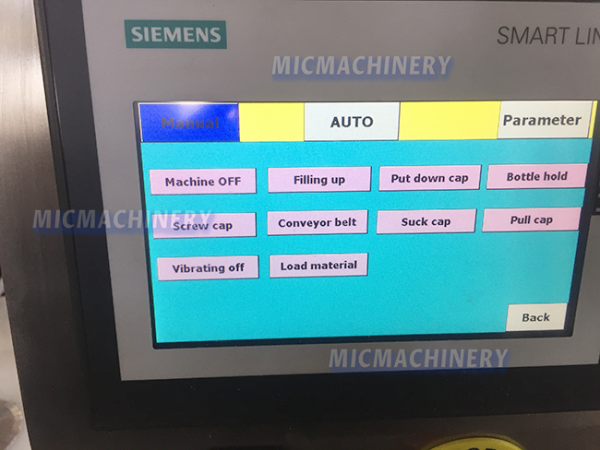

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

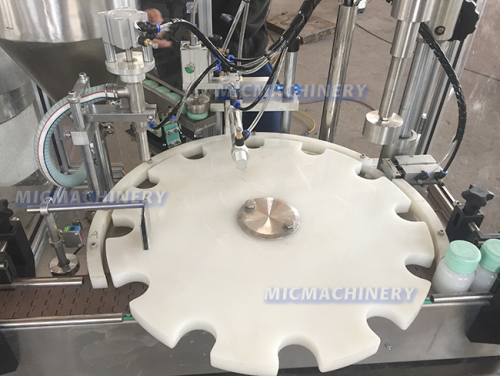

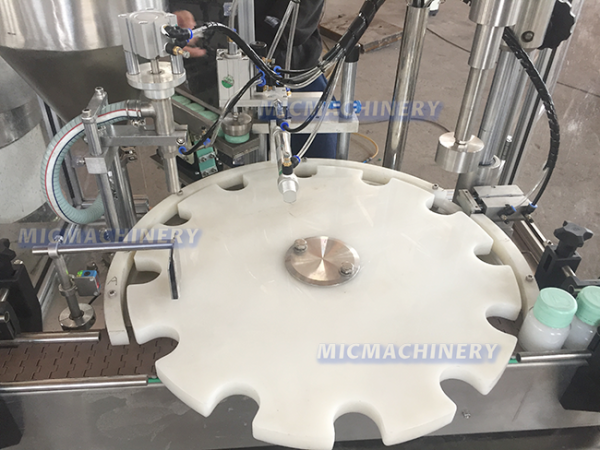

The main platform

The picture includes chuck, negative vacuum filling head,and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient.We can customize this turntable, filling head, screw cap and so on.

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,sauce,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

25-30p/m |

30-50p/m |

30-40p/m |

25-30p/m |

20-30p/m |

15-25p/m |

30-40p/m |

30-50p/m |

|

Filling arrange |

50-250ML |

10-100ML |

10-100ML |

10-100ML |

30-120ML |

2-30ML |

10-100ML |

20-150ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KG |

650KG |

650KG |

650KG |

600KG |

In addition to,we have Skincare filling machine.If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.