- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

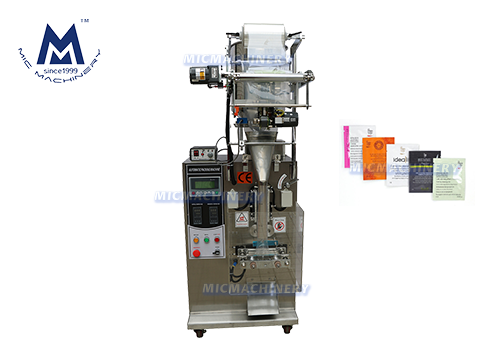

In the realm of skincare manufacturing, where precision meets convenience, the Skincare Sachet Filling Machine(Skincare Filling Machine) emerges as a pivotal solution, seamlessly marrying technological innovation with the demand for individualized, single-use skincare applications. This state-of-the-art machine redefines the skincare packaging landscape, providing manufacturers with a versatile tool to meet the dynamic needs of modern consumers. By unraveling its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we delve into the essence of excellence in skincare sachet filling. From luxurious serums to revitalizing masks, this machine ensures each skincare sachet is filled with accuracy, consistency, and the promise of on-the-go indulgence.

Product Characteristics:

The Skincare Sachet Filling Machine(Skincare Filling Machine) showcases an array of exceptional characteristics meticulously engineered for precision and efficiency. Crafted from durable materials, often stainless steel, these machines ensure longevity while adhering to the highest standards of quality. Featuring automated dosing systems, filling nozzles, and customizable settings, they cater to a spectrum of skincare viscosities, ensuring each sachet receives a consistent and accurate fill. Compact in design, these machines are tailored for sachet applications, optimizing space while maintaining productivity. Advanced sensors and user-friendly interfaces enhance operational efficiency, minimizing wastage and maximizing the efficiency of sachet production. Equipped with anti-drip mechanisms and secure sealing, these machines preserve the integrity of skincare formulations, delivering single-use sachets that captivate with their quality and convenience.

Product Applications:

The applications of the Skincare Sachet Filling Machine are designed to meet the evolving preferences of consumers for on-the-go skincare solutions. Skincare manufacturers utilize these machines for efficient and precise filling of serums, creams, masks, and various formulations into individual sachets. Ideal for travel-sized or sample-sized packaging, these machines cater to the demand for convenience and portability in the skincare industry. Whether producing small batches of specialized products or large-scale manufacturing of sachet collections, these machines ensure uniformity in dosage, presentation, and the preservation of skincare formulations in compact, single-use sachets.

Mechanical Principle:

At its core, the Skincare Sachet Filling Machine operates on advanced mechanical principles designed for precision, speed, and versatility. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of skincare products into individual sachets. Sealing mechanisms, employing high-speed heat sealing or ultrasonic sealing technology, secure the sachets, preserving the freshness and effectiveness of the skincare formulations. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of skincare sachet filling operations.

In conclusion, the Skincare Sachet Filling Machine stands as a symbol of precision and convenience in the skincare packaging domain. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for skincare manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the accuracy of skincare sachet filling but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in the creation of on-the-go skincare essentials, it continues to shape the way skincare products are filled, ensuring each sachet embodies the essence of precision and the promise of convenient indulgence.

Control Panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

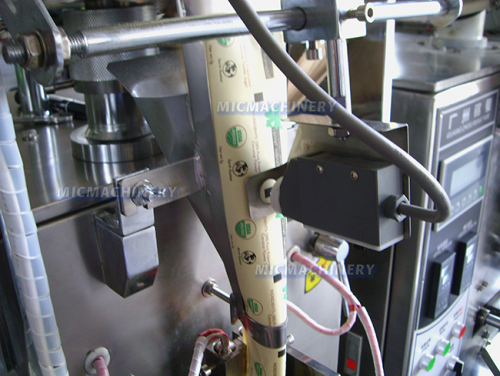

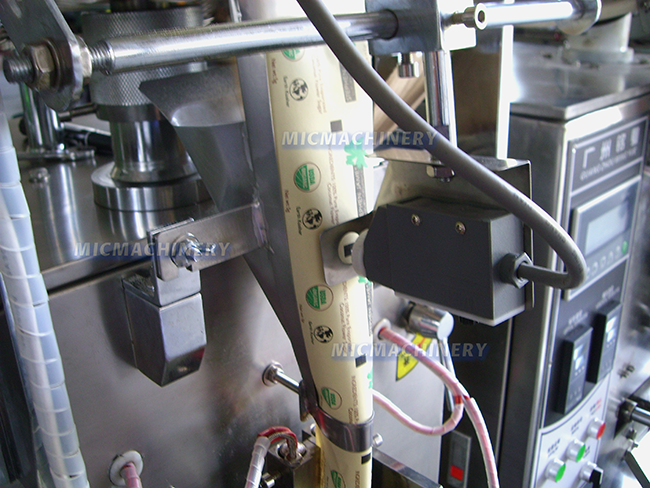

Sensor

The sensor senses the location of the film, telling the machine where to cut the bag.Photoelectric and tracing system or computer system can be provided without your specific requirements.

Bag Former

This machine can finish forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

This machine is suitable for automatic packaging of liquid of foods, medicine and chemicals,such as pesticide,shampoo,body foam bath lotion, facial cream, ingredient oil, fruit sauce,tomato ketchup and honey shower gel, skin lotion, toothpaste, cosmetic cream, fruit jam, edible oil, soy etc .

Machine features:

1. This machine can finish : forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;

2. Photoelectric and tracing system or computer system can be provided without your specific requirements.

3. The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

4. This machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

5.Eye Mark System ,machine can cut complete logo.

6.Machine Stop Automaticlly if it is out of film.

7.Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

Applicable packing film:

Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

In addition to,we have Skincare filling machine.If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.