- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In industries where precision and efficiency are paramount, the Small Bottling Machine emerges as a critical asset, specifically designed to handle the packaging needs of small bottles. Let's delve into its performance, focusing on its role as a small bottling machine and its contribution to the overall efficiency of a small bottling line.

Maximizing Efficiency with Small Bottling Machine

Precise Filling: The Small Bottling Machine excels in delivering precise fills for small bottles. Equipped with advanced dosing mechanisms and controls, it ensures uniform and accurate filling, crucial for maintaining product consistency and quality across various industries.

High-Speed Operation: As a specialized machine, it boasts high-speed filling capabilities tailored for small bottles. Its efficient operation minimizes production time, optimizing throughput and enabling manufacturers to meet tight deadlines and high demand periods.

Versatility and Adaptability: Serving as a key component in a small bottling line, this machinery offers versatility in handling various bottle sizes, shapes, and products. Whether filling liquids, oils, syrups, or other formulations, it accommodates diverse production requirements, providing flexibility for manufacturers to adapt to changing market needs.

Serving as a Small Bottling Machine and Part of a Small Bottling Line

Small Bottling Machine: The Small Bottling Machine serves as the core of the packaging process for small bottles. Its precise dosing mechanisms and sterile filling capabilities ensure consistent fills, minimizing product wastage and maximizing dosage accuracy for various applications.

Small Bottling Line: As an integral part of a small bottling line, this machinery integrates seamlessly with other equipment such as bottle rinsers, cappers, labelers, and conveyors. Its modular design allows for easy customization and expansion, providing manufacturers with a scalable solution to meet growing production demands.

Small Bottle Filling Machine: The Small Bottle Filling Machine serves as a specialized solution for accurately filling small bottles with liquids or products. Its precise dosing mechanisms and sterile filling capabilities ensure consistent fills, minimizing product wastage and maximizing dosage accuracy for various applications.

Conclusion

The Small Bottling Machine plays a crucial role in various industries, offering precision, efficiency, and adaptability in packaging small bottles. Whether serving as a standalone small bottling machine or as part of a small bottling line, it ensures the quality and integrity of packaged products. By investing in this advanced equipment, manufacturers can streamline their packaging processes, meet market demands, and deliver high-quality products to consumers efficiently.

This machine is a fully automatic model specially designed for perfume bottles.

The process is: bottle feeding-filling-press the spray-seal spray(crimping) -put the outer cover-press the outer cover Of course you can also choose to put the spray and outer cover manually.

This machine Advantages:

Small and saving space

Efficient and precise

Easy to operate and flexible

Stainless steel body, neat and beautiful

Main features of the machine:

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) Running in a high automatization and intellectualization, no pollution

4) Self bottle loaded

5) Stainless steel body, neat and beautiful

6) No bottle no filling

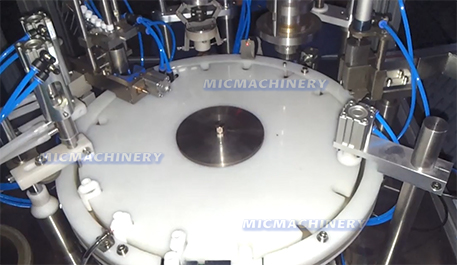

The main platform

The picture includes chuck, negative vacuum filling head, and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient.We can customize this turntable, filling head, screw cap and so on.

Negative pressure filling

1. It can keep your finished product level at the same level with very little error. If your product container is made transparent, it can have a better visual effect in sales

2.It can be filled without dripping When filling without dripping, the cosmetic industry also needs to achieve a high standard of hygiene, negative vacuum filling without dripping to avoid the risk of cross infection

3.It is also very suitable for the filling of liquid which is easy to bubble during the filling process. Because this machine will suck all the foam in the bottle mouth at the end. The sucked foam and liquid will enter the liquid storage tank and it will not be wasted.

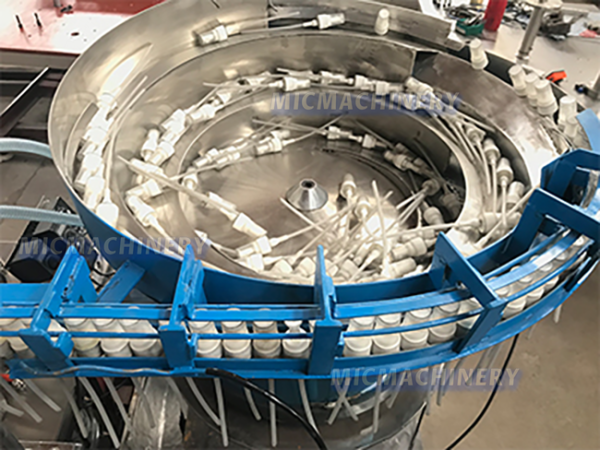

Spray loading automatically

Spray-head feeding cage with vibrating piate is connected to a pipe that carries the spray head ,They automatically arranges the Spray-head and deliver the Spray-head.

In this way, the bottle is covered in a consistent process, reducing the manual contact with the bottle process, and ensuring better hygiene,At the same time, labor costs are reduced

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Volume |

10-100ml |

|

Filling nozzle |

2 or 3 nozzles |

| Output |

20-30 bottles each minute |

|

Filling Error |

≤±1% |

| Power Supply |

220v 50Hz |

| Capping Rate |

≥99% |

|

Air supply |

1.3 m3/h 0.4-0.8Mpa |

|

Power |

2.0 kw |

|

Dimension |

1800*1000*1500mm |

|

Setup component

|

Brand |

|

Rack material |

SUS 304 |

|

Tank, nozzle, liquid touches place |

SUS 304 / medical silica gel |

|

Air componnet |

Airtac |

|

Touch screen |

Siemens Germany 21 cm color |

|

Sensor |

LEUZE Germany or SICK |

|

Relay & air switch |

Schneider French |

|

Transducer Motor |

Schneider French |

|

Conveyor material |

82mm width SUS 304 Chain belt |

|

Conveyor motor |

AC motor China brand |

|

Filling form |

Piston filling (80-90) and vacuum filling (for accuracy) |

|

Turnable tray motor, capping motor, |

China brand |

|

Explore parts |

SUS 304, Positive oxidation treatment aluminum alloy Electroplate No.#45 steel and plastic. |

|

Vacuum pump |

China brand |