- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

The Automatic Vial Filling and Capping Machine offers precise liquid filling and secure capping for vials. Its efficient vial filling system ensures reliable, high-speed performance for pharmaceutical and cosmetic production lines.

Our vial filling machine is built to meet stringent GMP and ISO requirements, making it suitable for cleanroom installations and high-precision environments. It features servo-driven filling systems for consistent dosing, paired with a no-contact filling design that minimizes the risk of contamination. The compact structure saves valuable production space while maintaining high efficiency and output.

At the heart of the machine is a highly reliable vial filling system, capable of handling various vial sizes with minimal format changeover time. The filling volume is easily adjustable through the control panel, and the advanced sensors ensure real-time feedback for volume verification and filling accuracy.

Key Features and Advantages

Mic Machinery’s automatic vial solution offers a wide range of performance benefits, including:

√ Precision Filling: Equipped with peristaltic or piston pumps to deliver exact volumes into each filler vial.

√ Automated Cap Placement: Cap sorting, positioning, and sealing are all synchronized with the filling process.

√ Sterile Environment Compatibility: The system supports laminar airflow units and can integrate with isolator or RABS technologies.

√ Scalability: Modular design allows it to scale up for higher production demands or adapt to new product types.

These features ensure operational stability and consistent product quality across production batches.How the System Works?

The filling and capping cycle involves a series of coordinated steps:

1)Vials are automatically fed into the system via an infeed conveyor.

2)Each filler vial is accurately filled through non-contact nozzles to avoid contamination.

3)Vials proceed to the stoppering or capping station, where closures are applied with precision torque control.

4)Outfeed conveyors transfer the completed vials to downstream packaging or inspection equipment.

This synchronized workflow ensures smooth and uninterrupted production with minimal operator intervention.

Designed for Customization and Compliance

At Mic Machinery, we understand that different manufacturers have unique production goals. That’s why our vial filling machine can be tailored with options such as:

● Nitrogen flushing systems for oxygen-sensitive drugs

● Integrated visual inspection units

● CIP/SIP functionality for cleanroom operations● Compatibility with glass or plastic vials

Each configuration is supported by our technical team to ensure smooth integration into your existing vial filling system.

A Trusted Partner in Pharmaceutical Manufacturing

With years of expertise in liquid filling technology, Mic Machinery is a trusted partner for companies seeking accuracy, hygiene, and reliability. Our Automatic Vial Filling and Capping Machine combines technical excellence with real-world usability. Whether you're working with vaccines, oncology drugs, or diagnostic reagents, we provide the tools you need to maintain product safety and production efficiency.

Filling Head

The filling head in a Vial Filling and Capping Machine ensures precise, sterile, and consistent liquid dosing into each vial. It works with peristaltic or piston pumps and is designed for non-contact operation, minimizing contamination while maintaining high accuracy and production speed.

Liding machine

The lidding machine in a Vial Filling and Capping Machine securely places and seals caps or stoppers onto filled vials with precision. It ensures airtight sealing to maintain product sterility, using servo-driven torque control for consistent and reliable capping across all vials.

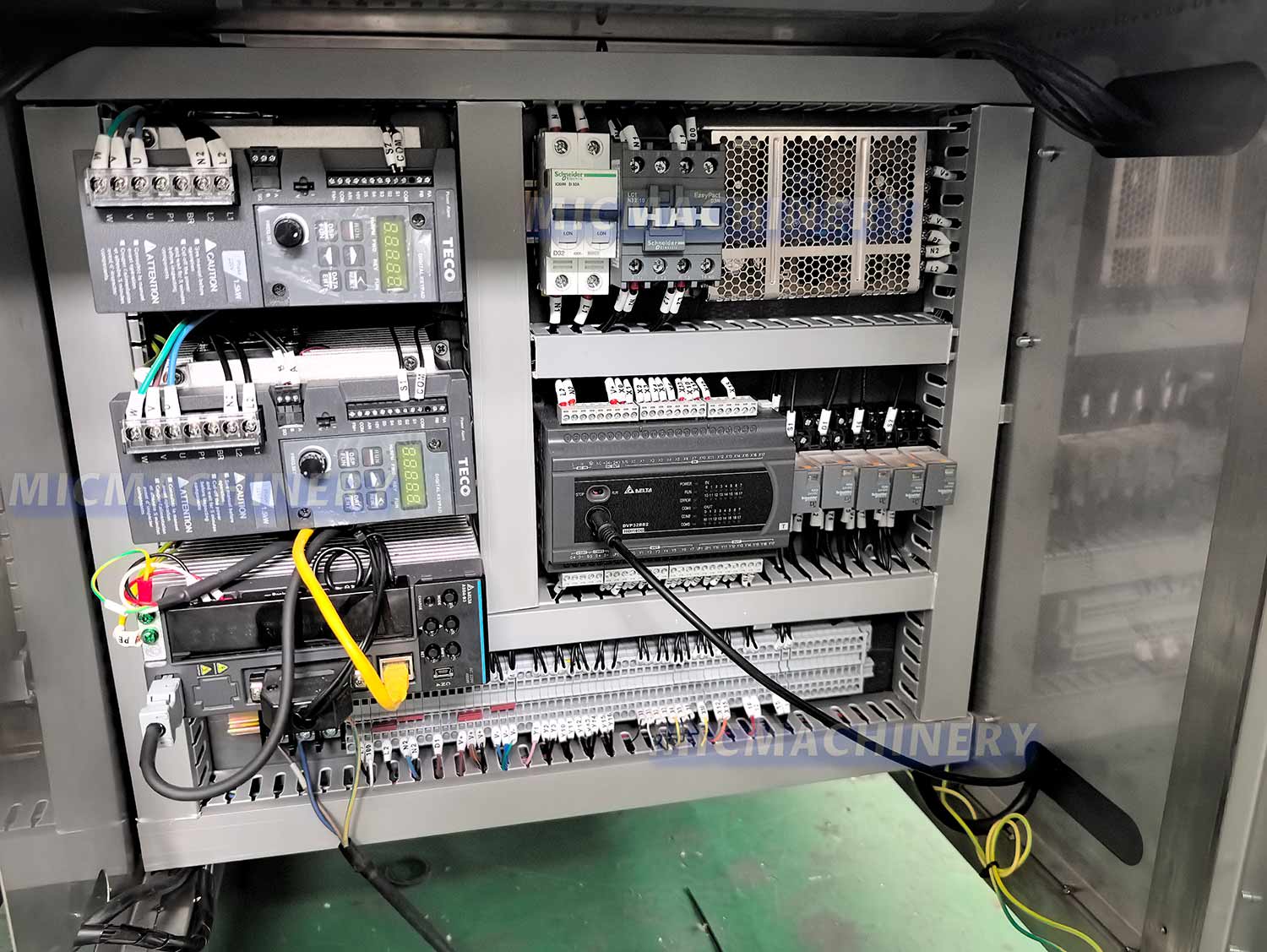

Electrical Machinery

The electrical machinery in a Vial Filling and Capping Machine powers precise automation, including servo motors, PLC controls, and touch screen interfaces. It ensures synchronized filling, capping, and vial transport, enhancing accuracy, safety, and production efficiency.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Specification |

Details |

|

Model |

MC--LL40 |

|

Filling Volume |

1–50 ml |

|

Filling Speed |

20–30 pcs per minute |

|

Gas Consumption |

40m³ per hour |

|

Power Supply |

220V 50HZ |

|

Power |

2.5KW |

|

Weight of the Whole Machine |

450KG |

|

Overall Dimension |

L4000mm * W1600mm * H1850mm |

- MIC-LL45 Automatic Vial Filling Machine ( 10-25 Bottles/min )

- MIC Double Station Vial Filling And Capping Machine

- Automatic Vial Filling and Capping Machine

- Automatic Vial Filling Machine ( 20-30 Bottles/min )

- Vial Filling And Capping Machine ( 20-40 Bottles/min )

- Vial Filling Equipment ( 20-40 Bottles/min )

- Liquid Vial Filling Machine ( 30-90 bottles/min )

- Spray vial filling line(30-150 Bottles/min)

- Small Vial Filling Machine ( 200 Bottles/min )

- Powder Vial Filling Machine

- Vial Filling Machine ( 7000-24000 pcs/h )

- Plastic Vial Filling Machine

- Vial Filling Machine(60-600 Bottles/min)

- Vial Filling Machine(30-200 Bottles/min)

- Automatic Vial Filling Machine(16 large-dose tracking 30-150 Bottles/min)

- Vial Liquid Filling Machine ( 130 bottles/min )

- High Speed Vial Filling Machine(16 Heads 30-450 Bottles/min)

- Sterile Vial Filling Machine ( 30-200 Bottles/Min )

- Four Heads Vial Filling Machine ( 30-80 Bottles/Min)