- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

It can be widely used in chemical, food, light industry, pharmaceutical, building materials and other industries.

Proction Interduction:

a. Integrate mixture, dispersion and wall scraper in one machine.

b. Mechanical seal, O ring seal or trapezoid seal for option material reaction can happen under vacuum condition.

c. High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time. No deposit and residuals.

d. Inverter control, various speed adjustment.

e. Mirror polishing to ensure its smoothness.

If you are interested in this machine,please contract us.We will be glad to recieve your inquiry.

Integrate mixture, dispersion and wall scraper in one machine.

Mechanical seal, O ring seal or trapezoid seal for option material reaction can happen under vacuum condition.

High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time. No deposit and residuals.

Inverter control, various speed adjustment.

Mirror polishing to ensure its smoothness.

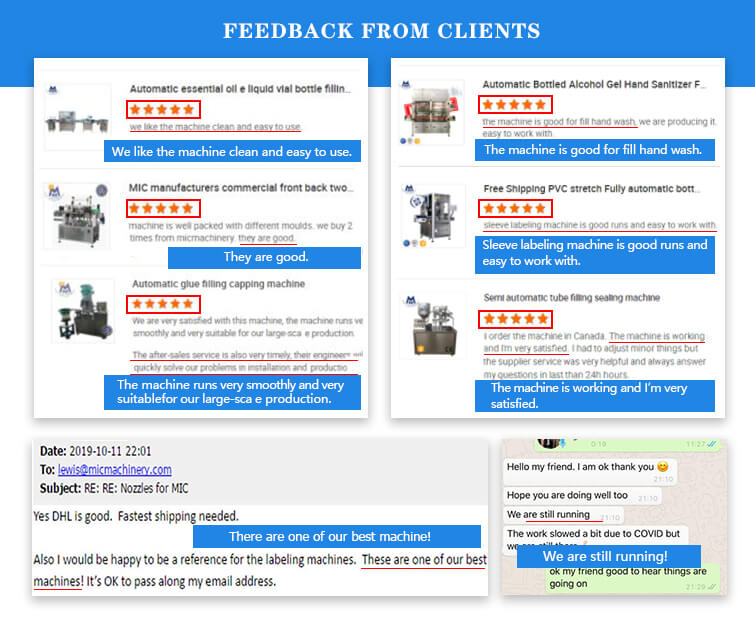

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Valtage |

220V |

|

Power |

45KW |

|

Material Barrel Design Volume |

650L |

|

Material Barrel Working Volume |

500L |

|

Vacuum Degree |

-0.08Mpa |

| Stitting Shaft Speed | 0-55rpm suitable |

|

Frequency Changer |

Watson (Shenzhen) |

| Motor | Kiper (Wuxi) |

| Reducition Gears |

Kiper (Wuxi) |

| Vacuum Pump | Maubec (Shenzhen) |

| 316 Stainless Steel | Tisco (Taiyuan) |

| 304 Stainless Steel | Tisco (Taiyuan) |

| Main Electrical Components | Chint (Zhejiang) |

| Bearing | NSK (Japan) |

| Sealing Element | Dingsheng (Taiwan) |