|

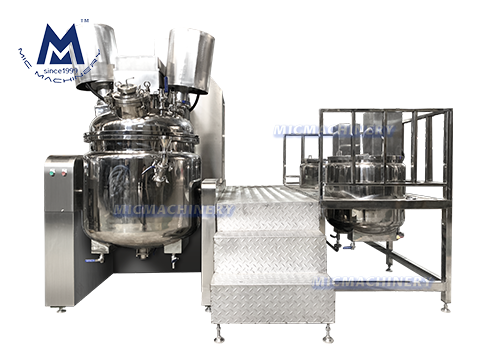

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

In the manufacturing and processing industries, achieving a homogeneous and stable mixture is often critical. This is where vacuum emulsifier mixers and related machinery come into play. This article explores various key equipment, including vacuum emulsifier mixers, vacuum mixers, vacuum mixer machines, and specialized terms like China vacuum mixer emulsifier, vacuum industrial mixer emulsifying agitator, and more. These keywords are strategically incorporated to optimize the content for SEO, highlighting the performance and applications of these technologies.

Vacuum Emulsifier Mixer

A vacuum emulsifier mixer is a specialized piece of equipment designed to blend and emulsify ingredients under vacuum conditions. This process removes air from the mixture, preventing oxidation and ensuring a smooth, stable emulsion. Vacuum emulsifier mixers are widely used in the pharmaceutical, cosmetic, and food industries to produce high-quality creams, lotions, ointments, and sauces. The vacuum environment enhances the quality and shelf-life of products by eliminating air bubbles and improving the consistency of the mixture.

Vacuum Mixer and Vacuum Mixer Machine

Vacuum mixers are versatile machines used for mixing, blending, and emulsifying under vacuum conditions. These mixers are essential for producing products that require a high level of homogeneity and purity. A vacuum mixer machine is equipped with advanced technology to control temperature, speed, and vacuum levels, providing precise control over the mixing process. This equipment is particularly useful in applications where minimizing air incorporation is crucial, such as in the production of pharmaceutical syrups, cosmetic emulsions, and food pastes.

China Vacuum Mixer Emulsifier: The term China vacuum mixer emulsifier refers to emulsifying mixers manufactured in China, known for their advanced technology and competitive pricing. Chinese manufacturers have become leaders in producing high-quality emulsifying equipment, offering cost-effective solutions for various industries. These machines are designed to meet international standards and are used globally for their reliability and efficiency.

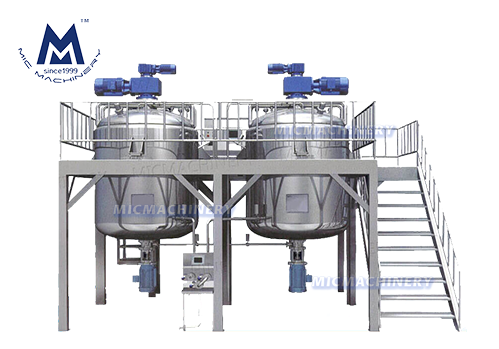

Vacuum Industrial Mixer Emulsifying Agitator: A vacuum industrial mixer emulsifying agitator is a robust piece of equipment used in large-scale industrial applications. It combines the functions of mixing, emulsifying, and agitating under vacuum conditions, making it ideal for processing large batches of products. This machinery is crucial for industries requiring precise mixing and emulsification, such as chemicals, cosmetics, and food processing.

Vacuum Emulsifying Machine and Vacuum Emulsifier Homogenizer

Vacuum emulsifying machines are designed to mix and emulsify ingredients in a controlled vacuum environment. This equipment is essential for producing stable emulsions with fine particle distribution, ensuring product uniformity and quality. The vacuum emulsifier homogenizer adds an additional homogenizing function, which further reduces particle size and enhances the stability of the emulsion. This is particularly important in creating high-quality pharmaceutical creams, cosmetic products, and specialty food items.

Vacuum Emulsifying Mixer Machine: The vacuum emulsifying mixer machine is an advanced version of the standard emulsifying mixer, incorporating vacuum technology to enhance the emulsification process. This machine ensures the complete removal of air, resulting in a smooth, bubble-free product. It is widely used in industries where product appearance and texture are critical, such as in cosmetics and personal care products.

Vacuum Emulsifying Mixer: A vacuum emulsifying mixer is specifically designed to mix ingredients under vacuum, ensuring a homogenous mixture free of air pockets. This machine is essential in applications where the presence of air can compromise product quality, such as in the production of pharmaceutical ointments and cosmetic creams.

Pricing and Market Considerations

When considering the purchase of emulsifying equipment, the vacuum emulsifying mixer price is a significant factor. Prices can vary based on the machine's capacity, features, and the manufacturer. China vacuum emulsifying mixer machine manufacturers offer a range of options that balance quality and cost, making them a popular choice in the global market. Chinese manufacturers are known for producing reliable and efficient machines at competitive prices, making it easier for businesses to access advanced technology without exceeding their budget.

Conclusion

In summary, vacuum emulsifier mixers, vacuum mixers, and related equipment are indispensable in various industries for producing high-quality, stable emulsions. The advanced technology of vacuum emulsifying machines and vacuum emulsifier homogenizers ensures precise control over the mixing process, resulting in superior product quality. The China vacuum mixer emulsifier market offers a range of cost-effective solutions, providing businesses with access to state-of-the-art equipment at competitive prices. Understanding the performance and benefits of these machines can help businesses make informed decisions, optimize their production processes, and maintain high standards of product quality.

Revolutionize Emulsification with a Vacuum Emulsifier Mixer

Introduction:

In industries that demand precise and efficient emulsification processes, the vacuum emulsifier mixer stands out as a versatile and powerful tool. This technical article explores the features, benefits, and applications of vacuum emulsifier mixers, highlighting their role in achieving superior emulsion quality and stability.

Vacuum Emulsifier Mixer:

A vacuum emulsifier mixer is an advanced piece of equipment specifically designed to create stable and high-quality emulsions. This machine combines the benefits of a mixer and a homogenizer while operating under vacuum conditions. The vacuum emulsifier mixer ensures efficient dispersion, uniform particle distribution, and reduced air entrapment, leading to emulsions with improved stability and texture.

Vacuum Emulsifier Homogenizer:

The vacuum emulsifier homogenizer is a versatile tool widely used in industries such as cosmetics, pharmaceuticals, food, and chemicals. This equipment combines the functions of emulsification and homogenization while operating under vacuum conditions. The vacuum emulsifier homogenizer enables precise control over parameters such as speed, temperature, and pressure, resulting in stable emulsions with fine droplet sizes and enhanced product quality.

Vacuum Emulsifier Machine:

A vacuum emulsifier machine is a highly efficient and reliable piece of equipment used for emulsion production. With its vacuum capabilities, this machine eliminates air bubbles and reduces the oxidation of sensitive ingredients. The vacuum emulsifier machine delivers consistent emulsion quality, improved stability, and extended shelf life, making it an essential tool in industries where product integrity and preservation are crucial.

Vacuum Emulsifier:

The vacuum emulsifier is a specialized device designed to create emulsions by dispersing two immiscible liquids under vacuum conditions. This equipment operates by reducing pressure, which minimizes air entrapment and enhances the stability and quality of the emulsion. Vacuum emulsifiers find extensive use in industries such as cosmetics, pharmaceuticals, and food, where fine emulsions and product consistency are vital.

Vacuum Homogenizer Emulsifier:

The vacuum homogenizer emulsifier is a versatile machine that combines the benefits of homogenization and emulsification while operating under vacuum conditions. This equipment ensures the reduction of particle sizes, uniform distribution of ingredients, and elimination of air bubbles, resulting in stable and homogeneous emulsions. The vacuum homogenizer emulsifier is commonly used in industries requiring precise control over the emulsification process, such as cosmetics, pharmaceuticals, and food manufacturing.

Vacuum Homogenizing Emulsifier:

The vacuum homogenizing emulsifier is an advanced piece of equipment that combines homogenization and emulsification capabilities under vacuum conditions. This machine effectively disperses and mixes immiscible liquids, resulting in stable emulsions with fine droplet sizes. With its precise control and superior emulsification performance, the vacuum homogenizing emulsifier is widely employed in industries seeking to achieve consistent and high-quality emulsion-based products.

Vacuum Mixer Emulsifier:

The vacuum mixer emulsifier is a versatile machine designed to mix and emulsify materials under vacuum conditions. This equipment provides efficient blending and dispersion, resulting in stable emulsions with enhanced product quality and stability. The vacuum mixer emulsifier is widely used in industries such as cosmetics, pharmaceuticals, and food, where precise emulsion control and high-performance mixing are paramount.

Conclusion:

Vacuum emulsifier mixers have revolutionized the emulsification process in various industries. With their ability to create stable and high-quality emulsions under vacuum conditions, these machines deliver superior product consistency, texture, and stability. By incorporating vacuum emulsifier mixers into their manufacturing processes, industries can achieve precise control, reduced air entrapment, and extended shelf life of emulsion-based products, leading to enhanced customer satisfaction and a competitive edge in the market.