- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of industrial manufacturing, efficiency and accuracy are paramount, especially when it comes to critical processes such as grease filling. Traditional methods often fall short in meeting the demands of modern production lines, leading to inconsistencies and inefficiencies. However, with the advent of advanced equipment like the four heads weighing linear machine, manufacturers can now achieve unparalleled performance and precision in grease filling applications.

Optimizing Performance with Four Heads Weighing Linear Machines

Four heads weighing linear machines represent the pinnacle of technological innovation in the realm of automated filling solutions. These machines are meticulously engineered to deliver exceptional performance and reliability, particularly in grease filling applications. Here's a closer look at their key features:

Multi-Head Efficiency: Equipped with four heads, these machines can simultaneously fill multiple containers with grease, significantly increasing production throughput. This multi-head design streamlines the filling process, minimizing downtime and maximizing efficiency.

Precision Weighing Mechanism: The weighing mechanism of these machines ensures accurate dosing of grease into each container. By precisely measuring the weight of the filled containers, they guarantee consistent fill levels, eliminating variations in product quality.

Linear Configuration: The linear configuration of these machines facilitates seamless integration into existing production lines. With a compact footprint and versatile design, they can adapt to various manufacturing environments, enhancing overall workflow efficiency.

Automating Grease Filling Machine with Precision

For manufacturers seeking automated solutions for grease filling, automatic grease filling machines offer the perfect blend of performance and convenience. These machines are specifically designed to streamline the filling process, minimizing human intervention and ensuring consistent results. Here's how they enhance efficiency:

Hands-Free Operation: Automatic grease filling machines eliminate the need for manual intervention, allowing operators to focus on other critical tasks. This hands-free operation reduces labor requirements and increases overall productivity.

Customizable Settings: These machines feature customizable settings that allow manufacturers to adjust fill volumes and dosing parameters according to their specific requirements. This flexibility ensures precise filling and optimal utilization of grease.

Reliable Performance: With robust construction and advanced automation technology, automatic grease filling machines deliver reliable performance day in and day out. Their intuitive controls and user-friendly interfaces make them easy to operate, minimizing the risk of errors and downtime.

Finding the Perfect Solution: Grease Filling Machines for Sale

In today's competitive market, finding the right grease filling machine is essential for maintaining a competitive edge. With a wide range of options available, including grease filling machines for sale, manufacturers can choose the perfect solution to meet their needs. Here are some factors to consider:

Performance: Look for machines that offer high-speed operation, precise dosing, and reliable performance to optimize production efficiency.

Versatility: Consider machines that can accommodate various container sizes and types, as well as different grease formulations, to ensure flexibility in manufacturing processes.

Affordability: While cost is a crucial factor, it's essential to balance upfront investment with long-term benefits such as increased productivity and reduced operating costs.

Conclusion: Elevating Grease Filling with Advanced Solutions

In the ever-evolving landscape of industrial manufacturing, efficiency, accuracy, and automation are key drivers of success. Four heads weighing linear machines, automatic grease filling machines, and other advanced solutions represent the future of grease filling, offering unparalleled performance and precision. By embracing these technologies, manufacturers can optimize production processes, minimize costs, and stay ahead of the competition in today's fast-paced market. Unlock the potential of grease filling machines and revolutionize your manufacturing operations for greater success.

1.This machine adopt PLC control system combine with weight system to control all machine.

2.Use fixed flow pipeline to set parameter.

3. Adopt large flow quality to control to reach approaching numerical( the set flow quality,such as set 20L, it will flow large quality to approaching 20L)

4.Then through small flow quality to supplement remain quality, in order to reach set quality filling, promise the filling quality is accuracy, and do not waste the material.

5.Filling volume range can adjust between 5L-25L.

6.This machine meeting GMP standard.

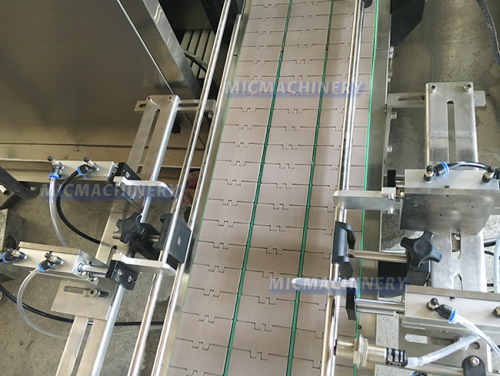

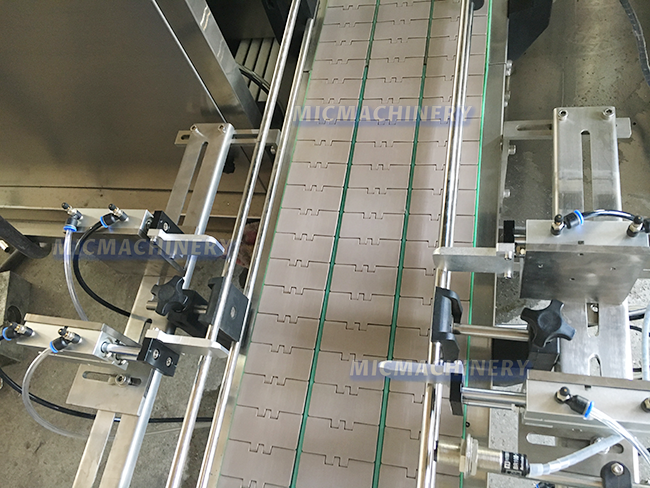

Conveyor belt

When the barrel is placed on it, the conveyor belt takes the barrel into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of barrel,The width between the two pipes can be adjusted according to your container,ensure smooth barrel safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the barrel to go out or, in order to send signals to filling station of screw cap.

A roller with a weighing device

This device is specially designed for the filling of large volume barrel products, with a weighing system below, during the filling process, the barrel is placed on the top, when the weight of the barrel reaches the specified amount, the machine automatically stops filling. To achieve precise filling, efficient work.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short we will try our best to provide you with satisfactory serviece,the following is our customers feedback

Filling head

4 heads

Filling volume range

5L-25L

Production speed

192-220 b/h (25L for example)

Voltage

380V three-phase four-wire

Power

3.0Kw

Long barrels

180mm-300mm

Wide application barrels

120mm-250mm

Apply high barrel

280mm-450mm

Filling error

≤±3‰

Air consumption

0.6m3/min

Work pressure

0.55Mpa-0.65Mpa

Size

2500mm × 1600mm× 2500mm

Weight

700 kg

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- MIC Grease Piston Filling Machine

- MIC Automatic Grease Gravity Filling Machine

- MIC Grease Gravity Filling Machine

- MIC Grease Pre-Made Pouch Filling Machine

- MIC-ZF2 Grease Filling Machine(1500 Bottles/H)

- MIC-R60-I Grease Tube Filling Machine (60-85 Tubes/m)

- MIC-ZF4 Grease Filling Machine (200-220 Barrels/h)

- MIC-ZF6 Grease Packing Machine (Speed 1300-1500 Bottles/m)

- MIC-ZF20 Automatic Grease Filling Machine (6000 Bottles/h)

- MIC-XG2 Grease Filling Machine Price (600-1200Bottles/h)

- MIC V01 Grease Filling Machine For Sale (5-25 Bottles/m)