- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

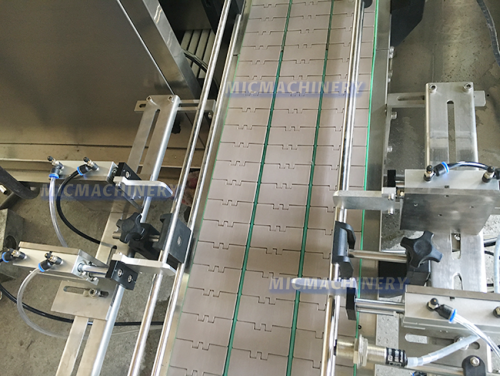

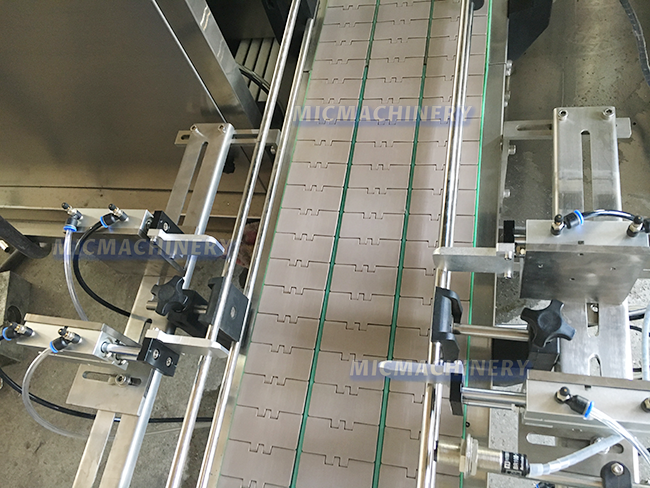

Conveyor belt

When the barrel is placed on it, the conveyor belt takes the barrel into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of barrel,The width between the two pipes can be adjusted according to your container,ensure smooth barrel safely from the conveyor belt moved .on the side of the conveyor is equipped with sensors that can automatically identify when the barrel to go out or, in order to send signals to filling station of screw cap.

A roller with a weighing device

This device is specially designed for the filling of large volume barrel products, with a weighing system below, during the filling process, the barrel is placed on the top, when the weight of the barrel reaches the specified amount, the machine automatically stops filling. To achieve precise filling, efficient work.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

pesticides,chemical,cosmetic and other corrosive,High Viscosity Materials, Liquid soap , oil product ,Lotion And So On |

|||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

|||||

|

Speed (basis on 50-500ml) |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||

|

Power |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,If you're looking for drum filling equipment,drum filling machine,drum filling system,automatic drum filling machine,drum filling line,drum packing machine,semi automatic drum filling machine,automatic drum filler,drum filling machine manufacturer,automatic drum filling equipment,it is a pleasure for you to visit our website anytime.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.