- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Revolutionizing Labeling Precision: Automatic Wet Glue Labeling Machines

In the realm of product packaging, achieving precise and efficient labeling is crucial for brand recognition and consumer trust. Automatic wet glue labeling machines stand at the forefront, offering unparalleled performance in labeling accuracy and speed. Let's explore the significance of these machines, focusing on wet glue labeling machines, cold glue labeling machines, and automatic wet glue labeling machines.

Enhancing Labeling Efficiency

Precise Label Application: Automatic wet glue labeling machines excel in applying labels with exceptional precision. Utilizing cold glue adhesive, these machines ensure secure and long-lasting label adhesion to various packaging surfaces. Their advanced application mechanisms guarantee consistent label placement, even on challenging container shapes and sizes, enhancing product aesthetics and brand appeal.

High-Speed Operation: Designed for high-volume production, automatic wet glue labeling machines offer rapid labeling speeds, maximizing throughput and minimizing production time. These machines feature automated label feeding, glue application, and label placement processes, enabling continuous and efficient labeling operations. With their high-speed capabilities, they meet the demands of fast-paced manufacturing environments without compromising on label quality.

Versatility and Adaptability: Automatic wet glue labeling machines are highly versatile, accommodating a wide range of label sizes, shapes, and materials. Whether applying paper labels, film labels, or foil labels, these machines ensure seamless integration into diverse packaging applications. Their customizable settings and quick changeover capabilities enable manufacturers to adapt to evolving labeling requirements and production demands with ease.

Distinguishing Features of Wet Glue Labeling Machines

Wet Glue Labeling Machine: As specialized equipment for cold glue labeling, wet glue labeling machines offer superior adhesion and durability for various packaging substrates. These machines utilize cold glue adhesive, which ensures strong and reliable label bonding, making them ideal for applications requiring extended product shelf life and resistance to moisture and temperature fluctuations.

Cold Glue Labeling Machine: Cold glue labeling machines, including automatic wet glue labeling machines, utilize a cold glue adhesive system to apply labels to containers. This method offers advantages such as minimal adhesive waste, reduced maintenance costs, and compatibility with a wide range of label materials. Cold glue labeling machines are preferred for their versatility, reliability, and environmentally friendly labeling solutions.

Automatic Wet Glue Labeling Machine: Representing the pinnacle of labeling automation, automatic wet glue labeling machines streamline labeling processes with fully automated label feeding, glue application, and label placement mechanisms. These machines feature advanced control systems and intuitive interfaces, allowing operators to monitor and adjust labeling parameters effortlessly. With their high-speed performance and precision, automatic wet glue labeling machines elevate labeling efficiency and product presentation in manufacturing operations.

Conclusion

Automatic wet glue labeling machines play a vital role in optimizing labeling precision and efficiency across diverse packaging applications. As cold glue labeling machines, they offer unmatched adhesion and durability, ensuring superior label quality and product presentation. Whether as wet glue labeling machines, cold glue labeling machines, or automatic wet glue labeling machines, their performance elevates brand recognition, consumer appeal, and manufacturing efficiency in the competitive marketplace. By investing in these advanced labeling solutions, manufacturers can achieve greater production throughput, cost savings, and brand success in the evolving landscape of product packaging.

In the realm of product packaging, achieving precise and efficient labeling is crucial for brand recognition and consumer trust. Automatic wet glue labeling machines stand at the forefront, offering unparalleled performance in labeling accuracy and speed. Let's explore the significance of these machines, focusing on wet glue labeling machines, cold glue labeling machines, and automatic wet glue labeling machines.

Enhancing Labeling Efficiency

Precise Label Application: Automatic wet glue labeling machines excel in applying labels with exceptional precision. Utilizing cold glue adhesive, these machines ensure secure and long-lasting label adhesion to various packaging surfaces. Their advanced application mechanisms guarantee consistent label placement, even on challenging container shapes and sizes, enhancing product aesthetics and brand appeal.

High-Speed Operation: Designed for high-volume production, automatic wet glue labeling machines offer rapid labeling speeds, maximizing throughput and minimizing production time. These machines feature automated label feeding, glue application, and label placement processes, enabling continuous and efficient labeling operations. With their high-speed capabilities, they meet the demands of fast-paced manufacturing environments without compromising on label quality.

Versatility and Adaptability: Automatic wet glue labeling machines are highly versatile, accommodating a wide range of label sizes, shapes, and materials. Whether applying paper labels, film labels, or foil labels, these machines ensure seamless integration into diverse packaging applications. Their customizable settings and quick changeover capabilities enable manufacturers to adapt to evolving labeling requirements and production demands with ease.

Distinguishing Features of Wet Glue Labeling Machines

Wet Glue Labeling Machine: As specialized equipment for cold glue labeling, wet glue labeling machines offer superior adhesion and durability for various packaging substrates. These machines utilize cold glue adhesive, which ensures strong and reliable label bonding, making them ideal for applications requiring extended product shelf life and resistance to moisture and temperature fluctuations.

Cold Glue Labeling Machine: Cold glue labeling machines, including automatic wet glue labeling machines, utilize a cold glue adhesive system to apply labels to containers. This method offers advantages such as minimal adhesive waste, reduced maintenance costs, and compatibility with a wide range of label materials. Cold glue labeling machines are preferred for their versatility, reliability, and environmentally friendly labeling solutions.

Automatic Wet Glue Labeling Machine: Representing the pinnacle of labeling automation, automatic wet glue labeling machines streamline labeling processes with fully automated label feeding, glue application, and label placement mechanisms. These machines feature advanced control systems and intuitive interfaces, allowing operators to monitor and adjust labeling parameters effortlessly. With their high-speed performance and precision, automatic wet glue labeling machines elevate labeling efficiency and product presentation in manufacturing operations.

Conclusion

Automatic wet glue labeling machines play a vital role in optimizing labeling precision and efficiency across diverse packaging applications. As cold glue labeling machines, they offer unmatched adhesion and durability, ensuring superior label quality and product presentation. Whether as wet glue labeling machines, cold glue labeling machines, or automatic wet glue labeling machines, their performance elevates brand recognition, consumer appeal, and manufacturing efficiency in the competitive marketplace. By investing in these advanced labeling solutions, manufacturers can achieve greater production throughput, cost savings, and brand success in the evolving landscape of product packaging.

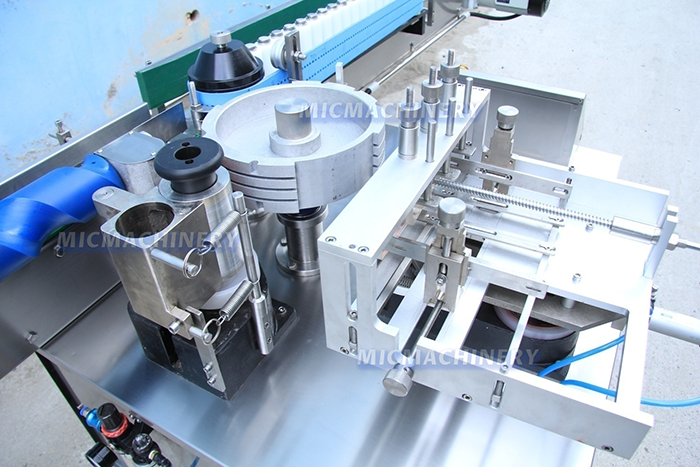

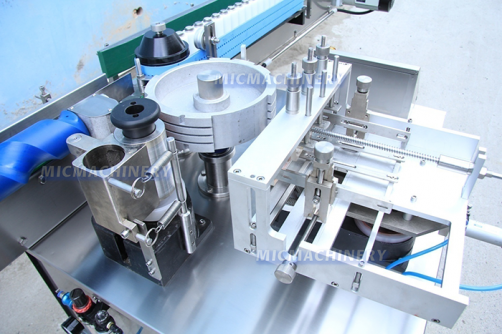

This labeling machine utilizes a combination of groove and stainless steel rollers, meticulously processed for precision. The adhesive application is flawless, ensuring no leaks. The specialized rubber roller remains resilient and wear-resistant through multiple operations, ensuring uniform and minimal glue usage.

Utilizing vacuum labeling and belt mechanisms, labels are seamlessly applied flat onto bottles. Incorporating photoelectric detection eliminates mislabeling due to missing bottles. The inclusion of a frequency converter allows for flexible motor speed adjustments, enabling precise control over labeling capacity.

This machine can operate autonomously or integrate into existing production lines. Manual adjustment features facilitate easy operation. Swift adaptation to various bottle specifications is achieved through the quick replacement of parts such as sticks and vacuum belts, minimizing human error in adjustments.

Manufactured with precision and using standardized components, maintenance is convenient. The incorporation of predominantly imported components ensures stability, enhanced performance, prolonged lifespan, and reduced maintenance requirements.

Utilizing vacuum labeling and belt mechanisms, labels are seamlessly applied flat onto bottles. Incorporating photoelectric detection eliminates mislabeling due to missing bottles. The inclusion of a frequency converter allows for flexible motor speed adjustments, enabling precise control over labeling capacity.

This machine can operate autonomously or integrate into existing production lines. Manual adjustment features facilitate easy operation. Swift adaptation to various bottle specifications is achieved through the quick replacement of parts such as sticks and vacuum belts, minimizing human error in adjustments.

Manufactured with precision and using standardized components, maintenance is convenient. The incorporation of predominantly imported components ensures stability, enhanced performance, prolonged lifespan, and reduced maintenance requirements.