- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

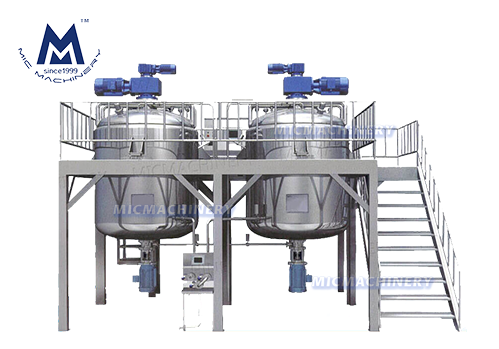

This emulsifier mixer consists of: oil tank, water tank, vacuum homogeneous emulsifying machine, heating system, mixing system, vacuum system, hydraulic lifting system, operation control cabinet, piping system. It is the most suitable equipment to produce high-grade skin care creams or other creams products.

Oil tank capacity 700L; water tank capacity 500L; primary pot capacity 1300L, working volume 1000L; limiting vacuum -0.09MPa.

Size: 4800mm×3000mm×2500-3850mm

Material: Inner wall is 316 stainless steel, jacket, outer layer are made by 304 stainless steel, inner and outer are polished, the surface handled by special light treatment.

Mixing system: both oil tank and water tank assemble disperser of 1.1KW, to make the water and oil heated more quickly and evenly.

mixer emulsifier pot: made of three decks. Interlayer thickness 6mm, middle layer thickness 6mm, outer layer thickness 3mm, special light treatment The homogenizer is on the top of the emulsifying pot, adjustable time setting depends on the product homogenization need, voltage 380V, power 11KW, made in Shanghai and uses German technology, the highest speed 3000 r / min. The material moves in a high speed between the rotor and stator, what can engender a strong hydraulic shear power to dispersing materials, meanwhile it can engender centrifugal power to extrude, milling, crash the material, ultimately make the material mixing, stirring, diminution to the desired requirements. A lighting hole on the pot cover to observe the states of homogeneity. Entrance for spots of material provide possibility to add essence and suchlike materials. Either pour-out the material by tilting the pot or from the bottom, the latter way can make the materials enter the filling machine directly for quantitative filling. Easy to clean.

Vacuum system: voltage 380V, power 2.2KW, materials in water tank and oil tank are absorbed into the primary pot in vacuum. The rotary-vanepump is made by Haibo Kang Company in Shanghai, which can remove the air bubble to improve the homogenizing effect.(circulating cooling by water)

Mixing system: voltage 380V, power 4KW, 10-120 r / min. Monitoring with transparent filter, scraping the interlayer when mixing, frequency control.

Heating system: 2KW electric heating device attaching at the bottom. Heating with temperature display, easy to control.

Hydraulic lifting: voltage 380V, power 4KW. Lifting is easy to operate, so the material can be effectively emulsified in a closed condition.

Control System: The control system is equipped with digital time relay device, so it can adjust time and speed of homogenizer based on different material. All control buttons are concentrated together,clear at a glance.

Liquid Mixer Pharmaceutical offer a wide range of features that enhance emulsification and homogenization efficiency and versatility. These machines can handle a variety of substances, including creams, lotions, suspensions, and more. With adjustable speed settings, precise temperature control, and programmable parameters, manufacturers have the flexibility to optimize the emulsification and homogenization process according to specific product requirements. Some models may also incorporate additional functionalities, such as vacuum capabilities or inline milling, further enhancing the emulsification and homogenization process.

Efficiency and consistency are paramount in manufacturing processes, and Liquid Mixer Pharmaceutical are designed to meet these demands. With their advanced emulsification and homogenization capabilities, these machines can process large volumes of substances, ensuring uniformity and minimizing product variation. The innovative technology employed in homogenizer emulsifier mixers enables efficient dispersion, emulsification, and homogenization, ultimately optimizing production processes and reducing processing times.

Mixing Tank

made of three decks. Interlayer thickness 6mm, middle layer thickness 6mm, outer layer thickness 3mm, special light treatment The homogenizer is on the top of the emulsifying pot, adjustable time setting depends on the product homogenization need, voltage 380V, power 11KW, made in Shanghai and uses German technology, the highest speed 3000 r / min.

Oil And Water Tank

Used for pre-heating and pre-stirring materials, and then transported to the main pot for secondary stirring homogenization. The electric heating power of the sandwich layer is 2.2KW, and the outer layer is equipped with asbestos insulation device, which not only ensures that the heat energy is reduced and the scalding of employees is avoided. Two cases quota fixed stirring dispersions 1.1KW, so that oil and water heating more quickly and evenly.

If you want to know more models of filling machine, you can refer to the table below:

|

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

In addition to,If you're looking for vacuum emulsifying mixer price,vacuum emulsifying mixer machine,vacuum homogenizer cream mixer,emulsifier machine,emulsifying mixer,vacuum emulsifier,vacuum homogenizer mixer,vacuum homogenizer,double planetary mixer,silicone mixers,planetary vacuum mixer,vacuum planetary mixer,ross planetary mixer,silicone mixer,ross double planetary mixer,industrial planetary mixer,planetary mixer pharmaceutical,silicone planetary mixer,silicone mixer machine,planetary mixer in pharmaceutical industry,pharmaceutical planetary mixer.it is a pleasure for you to visit our website anytime.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Device Name |

1000L Emulsifying Machine |

|

Working ability |

Design volume: 1300L |

|

Working volume:1000L |

|

|

Minimum operating volume: 250L |

|

|

Material |

Contact Parts: 316 stainless steel thickness: 6mm |

|

Interlayer: 304stainless steel thickness: 6mm |

|

|

Outer layer: 304stainless steel thickness: 3mm |

|

|

Weight |

3000kg |

|

Size |

4800mm×3000mm×2500-3850 mm |

|

Service life |

10 years |

|

Stirring |

Fixed paddle stirring, PE blade Scraping |

|

Homogenizer |

Power: 11KW |

|

Motor speed: 3000r/min |

|

|

Particle size: 0.2-0.6um |

|

|

Uncapping |

Hydraulic lift |

|

Heating |

Steamy heating |

|

Discharge |

Steamy toppling discharge |

|

Process parameters |

Working pressure: -0.09MPa |

|

Flimsy parts |

1 year renewal except artificial |

|

Warranty period |

1 year |

|

Inverter |

Taian (Taiwan) |

|

Motor |

Huadiao (Nanjing) |

|

Reducer |

Jiahe(Zhejiang) |

|

Vacuum |

Boer Kang (Shanghai) |

|

304 stainless steel |

Taigang(Tianjin) |

|

Main electrical components |

Zhengtai(Zhejiang) |

|

Hydraulic press |

Guangde(Wuxi) |

|

Hydraulic cylinder |

Guangde(Wuxi) |