- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Maximize efficiency and precision in cream packaging with our state-of-the-art Automatic Soft Tube Filling Machine(Filling machine for creams). Engineered for seamless operation, this innovative solution is specifically designed to cater to the unique needs of cream filling applications.

Effortlessly fill soft tubes with creamy formulations using our advanced machine. Whether you're packaging moisturizers, serums, or specialty creams, our system ensures precise filling, minimizing product wastage and ensuring consistent results with every use.

Seamless integration into your production line is facilitated by our user-friendly interface and customizable settings. With adjustable fill volumes and intuitive controls, you have complete flexibility to tailor the machine to your specific cream filling requirements, ensuring optimal performance every time.

Boost productivity and minimize downtime with the reliability and durability of our Automatic Soft Tube Filling Machine. Built to withstand the demands of automatic operation, our equipment delivers exceptional performance, ensuring consistent output and premium product quality.

Invest in efficiency-driven automation with our Automatic Soft Tube Filling Machine for creams. Stay ahead of the competition and meet the demands of today's market with ease. Contact us now to discover how this advanced solution can transform your cream packaging process.

A soft tube filling and sealing machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food and chemical etc.

This machine function is:

1. Automatic tube loading

2. Automatic sensoring when the tube is coming

3. Then pistion filling for cream

4. Inner heating and outer heating

5. Tube sealing and date printing

6. Tail cutting automatically

7. Finishing and sealing check

This MIC-R60 auto soft tube filling & sealing machine is a 1 filling head filling machine with a heating gun. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

The control panel

The control panel on the filling machine is the core of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly.

Filling head

When the tube reaches the specified position, automatic identification of sensors, control by internal program to send signals for filling station, when the tube comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

The size of the filling head can be customized according to the caliber of the tube, ensuring that this machine is absolutely suitable for your product.Adopt Piston Pump Control Filling Head, Ensure Filling Volume Error Control In +/-1%.

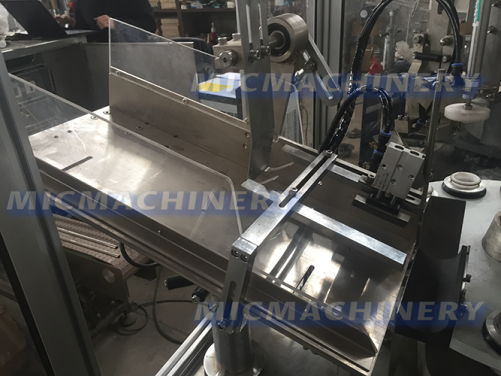

The main platform

Pictures include turntables, filling heads, sensors, heating heads, cutting and date printing stations. Its function is clear and easy to clean. Main workflow: automatic on-line through pipeline. When the pipe comes, the sensor automatically recognizes it, sends a signal to the gas station, and begins refueling. After filling, the end of the pipe is heated, flattened, cut, date printed, and finally the pipe is topped.

We can customize this turntable, filling head, etc

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250kg |

300KG |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250kg |

250Kg |

475KG |

850Kg |

in short,we will try our best to provide you with satisfactory service,the following is our client feedback: