- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Product Characteristics:

Our glass filling machine is distinguished by advanced features that set it apart in the market. Boasting a twenty-head linear filling mechanism, this system stands as a testament to precision and speed. Each fill is executed with seamless accuracy, showcasing the machine's commitment to reliability and consistency. Its design ensures a smooth and reliable packaging process, making it an indispensable asset for businesses seeking to optimize their liquid packaging operations. The machine's durability, speed, and precision make it a remarkable investment for those aiming to enhance their production capabilities.

Product Application:

Versatility is the key strength of our glass bottle filler, tailored to accommodate the filling of glass bottles with Honey, Cream, and Oil. The twenty heads linear filling machine excels in handling a diverse range of viscosities, ensuring a controlled and spill-free filling process. Whether you're a small-scale producer or a large-scale industrial enterprise, this machine seamlessly adapts to various production environments. It stands as the optimal solution for achieving outstanding results in packaging honey, creams, and oils in glass bottles, maintaining the highest standards of product integrity.

Mechanical Principle:

At the core of this glass packaging machine lies a sophisticated twenty-head linear filling mechanism, operating seamlessly to provide unparalleled efficiency. This enables the simultaneous filling of multiple bottles, accelerating the production process while upholding a high level of precision. The machine's intuitive design minimizes downtime, contributing to enhanced productivity and a more streamlined production line. As a result, it stands as an excellent choice for businesses looking to elevate their liquid packaging operations.

In conclusion, our glass filling machine is not just a solution; it's a revolution in liquid packaging. With outstanding product characteristics, versatile applications, and robust mechanical principles, it stands as the ultimate choice for businesses seeking precision and efficiency in filling glass bottles with Honey, Cream, and Oil. Elevate your packaging process with a machine that goes beyond expectations, ensuring your products reach consumers with the quality they deserve.

Filling head

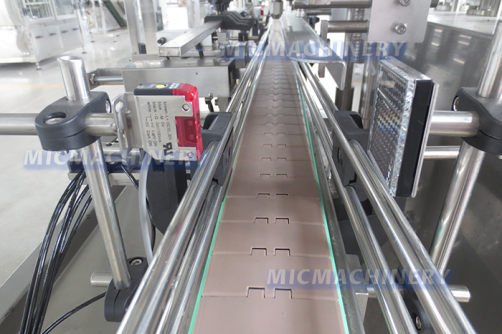

The jam is put into the material cylinder, and the piston to pump the jam into the measuring cylinder. Then the piston moves up to send the jam to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Six wheel cap rubbing machine

It consists of six small wheels, which work to tighten the lid on the bottle, and the six wheels are designed to ensure that the cap is screwed smoothly and perfectly.

The main working process is: the bottle of the filled material is transported out by the conveyor, the automatic capping machine puts the lid on the bottle, and then the six-round capping machine screws the lid. The whole process is convenient and fast, and effectively saves labor costs.

The height of the cap rubbing machine and the width of the middle can be adjusted according to your bottle size, and we try our best to ensure that every part of the machine is satisfactory.

1. Adopt PLC programmable control system with touch screen interface.

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

Jan filling machine mainly shows:

1.Place the bottle on the conveyor belt

2.Servo motor piston filling when the bottle reaches the designated spot

3.Bottle cap sorting and corking

4.Bottle cap screwing

5.Automatically label around bottle

6.Finally checking for sealing appearance

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,we have sauce filling machine,tomato sauce filling machine,hot sauce bottling machine,sauce bottling machine, jam filling machine.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

This is the good comment we received from our customers.If you need anything,you can also contract our sales.They will try their best to meet your needs.