Micmachinery's Ketchup Packaging Machines, Adapting to Custom Packaging Trends

The ketchup aisle isn’t what it used to be. Gone are the days of uniform glass bottles lining shelves—today, you’ll find squeeze pouches for kids, single-serve packets for food trucks, and even eco-friendly tubes for zero-waste shoppers. Custom packaging isn’t just a trend; it’s how brands connect with diverse audiences. For producers, this means one thing: their equipment can’t be stuck in the past. Micmachinery’s ketchup packaging machines are built for this new reality—flexible, precise, and ready to keep up with whatever packaging trend comes next.

Why Static Machines Can’t Keep Pace

Consumer expectations are driving a packaging revolution, and ketchup is no exception. Modern buyers want options tailored to their lifestyles: a 10ml sachet for a quick burger, a 300ml pouch for family dinners, or a 50ml tube for camping trips. It’s not just about size—texture matters too. Some prefer thick, chunky ketchup, while others opt for smooth, low-sugar variants, each needing packaging that preserves their unique consistency.

Brands are using packaging as a silent salesperson. A craft ketchup brand might choose a matte-finish pouch with hand-drawn labels to signal artisanal quality, while a budget-friendly brand leans into compact, lightweight packets to keep prices low. Even sustainability claims—like “100% recyclable” or “compostable”—are front-and-center on packaging, making it a key part of a brand’s identity.

The problem? Traditional Packaging machines are stuck in a one-size-fits-all mindset. Switching from jars to sachets often requires hours of retooling, with operators manually adjusting nozzles, conveyors, and sealing mechanisms. For brands trying to capitalize on seasonal trends—like heart-shaped packets for Valentine’s Day—this delay can mean missing the market window entirely.

Waste is another casualty of inflexible equipment. Overfilling, uneven seals, or misaligned labels are common with rigid machines, especially when handling varying ketchup viscosities. A mid-sized producer recently reported losing 8% of their product to spills and misfills—wasted ingredients that eat into profits and contradict sustainability goals.

Ketchup Packaging Machines Built for Adaptability

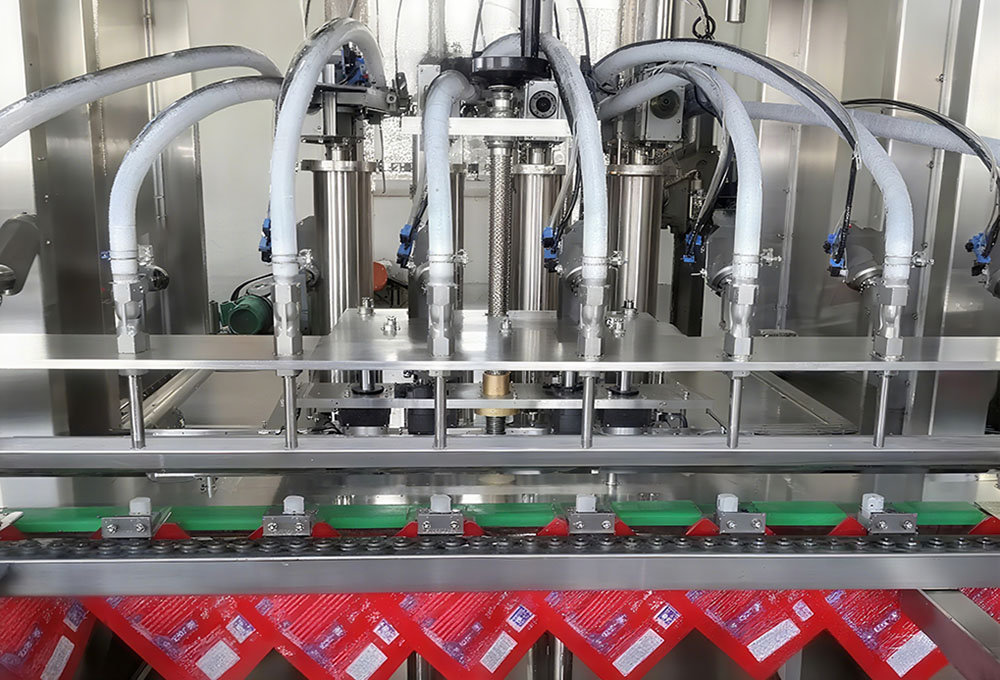

Micmachinery’s ketchup packaging machines start with a modular design that turns “one machine, one job” into a thing of the past. Every component—from filling nozzles to sealing bars—is interchangeable, allowing operators to switch between sachets, pouches, jars, and tubes in under 15 minutes. No special tools, no technical manuals—just a few quick adjustments, and the machine is ready for the next format.

Viscosity issues? Solved. These machines use smart sensors to “taste” the ketchup’s thickness, adjusting filling pressure in real time. Runny, low-sugar ketchup gets a gentle flow to avoid splatters; thick, seed-in varieties trigger a higher pressure setting to ensure smooth, complete fills. The result? Consistent portions, whether you’re Packaging 5ml packets or 1-liter bottles.

Sealing technology is just as flexible. Heat seals for plastic pouches, induction seals for jars, and peelable seals for single-serve packets—all are programmable with the touch of a button. For brands testing new materials, like plant-based films that melt at lower temperatures, Micmachinery pre-tests settings in their lab, ensuring the seal stays tight without damaging the eco-friendly packaging.

Automation cuts out human error. Unlike traditional machines that rely on manual adjustments, Micmachinery’s systems store 50+ preset configurations—so switching from “20ml sachet” to “500ml pouch” is as simple as selecting a saved setting. This not only speeds up changeovers but also reduces mistakes, with sensors flagging misaligned labels or weak seals before they reach the end of the line.

Micmachinery’s Collaborative Process

Micmachinery doesn’t sell machines—they design partnerships. The process starts with a deep dive into your operation: What’s your current production volume? Which packaging formats are top sellers, and which are on your wishlist? Even details like factory floor layout and existing conveyor systems are mapped out to ensure the machine fits seamlessly.

Cost is part of the conversation, not an afterthought. Micmachinery knows custom can sound expensive, so they focus on long-term savings. Their machines use 30% less energy than traditional models, and modular parts mean you can add a jar-filling module later instead of buying a whole new system. A small producer in Mexico, for example, started with sachet capabilities and added pouch filling a year later—no new machine needed.

Training ensures you’re never left guessing. Micmachinery’s technicians spend 2–3 days on-site, training your team to adjust settings, troubleshoot minor issues (like a clogged nozzle), and optimize speed. They even create a custom “cheat sheet” with step-by-step guides for your most common formats, so new operators can get up to speed quickly.

Support doesn’t end at installation. A 24/7 helpline connects you to engineers who can walk you through fixes via video call, and replacement parts ship within 48 hours—critical for avoiding costly downtime. One client in Australia had a sealing bar malfunction during a peak production run; Micmachinery walked their team through a temporary fix, then shipped a new part overnight, keeping the line running with just a 2-hour delay.

How Clients Are Winning with Micmachinery

Efficiency gains hit the bottom line fast. A European ketchup brand was running two shifts to keep up with demand for both bulk buckets and single-serve packets. After switching to a Micmachinery machine, they consolidated to one shift, cutting labor costs by 40%. The modular design let them handle both formats without pausing production, turning 8-hour days into 6-hour days with the same output.

Waste plummets with precise filling. A U.S.-based organic ketchup maker struggled with 12% product loss due to overfills and leaks. Within 2 months of using Micmachinery’s machine, that number dropped to 2%. “We’re not just saving tomatoes—we’re saving water, energy, and the fuel used to transport wasted product,” their operations manager noted, aligning with their sustainability mission.

Brands stay agile in fast-moving markets. When a viral TikTok trend pushed demand for “mini ketchup packets” (5ml instead of the standard 10ml) last summer, a Southeast Asian client reconfigured their Micmachinery machine in 2 hours and was shipping the new size within 3 days. Competitors with rigid machines took 3 weeks to source new parts—by then, the trend had peaked.

Smaller brands gain a level playing field. A startup ketchup company in Canada couldn’t afford multiple machines for their 5+ packaging formats. Micmachinery’s single system handles everything from 30ml squeeze tubes to 1-liter jars, letting them experiment with new sizes without overspending. “We’re competing with big brands now because we can adapt faster,” their founder said.

In a market where packaging trends shift as quickly as social media fads, Micmachinery’s ketchup packaging machines are more than equipment—they’re a strategic tool. They let brands stop working around their machines and start using them to chase opportunities, reduce waste, and tell their unique story.

For ketchup producers ready to trade inflexibility for adaptability, the choice is clear: Micmachinery builds ketchup packaging machines that grow with your brand, not against it. Because in today’s world, the best packaging isn’t just about holding ketchup—it’s about holding onto your customers.