- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of manufacturing, efficiency is key, and the Liquid Filling Machine stands as a beacon of optimization. This sophisticated equipment seamlessly integrates precision engineering with automation, revolutionizing the process of filling liquid containers. In this comprehensive guide, we'll explore the features, applications, and mechanical principles of the Liquid Filling Machine, shedding light on how it enhances productivity and quality in various industries.

Product Characteristics:

The Liquid Filling Machine boasts a plethora of features tailored for precision and efficiency. Crafted from high-quality materials and engineered with precision, it ensures durability and reliability in demanding production environments. Equipped with state-of-the-art dosing systems, customizable settings, and intuitive interfaces, this machine offers seamless operation while maintaining control over liquid filling processes. Its adjustable controls accommodate a wide range of viscosities, guaranteeing consistent and accurate fills for each container. With anti-drip mechanisms and secure sealing, it preserves the integrity of liquid formulations, delivering products of unparalleled quality.

Product Applications:

The applications of the Liquid Filling Machine span across industries, catering to diverse liquid filling needs. From pharmaceuticals to cosmetics, food and beverage to chemical manufacturing, this versatile machine excels in filling various types of liquids with precision and speed. Whether it's bottling pharmaceutical solutions, packaging cosmetics, or filling beverage containers, the Liquid Filling Machine streamlines production processes, reducing waste and maximizing efficiency. Its adaptability allows for seamless integration into existing production lines, making it a valuable asset for businesses of all sizes.

Mechanical Principle:

At its core, the Liquid Filling Machine operates on advanced mechanical principles designed for precision and reliability. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, it accurately measures and dispenses precise quantities of liquid into individual containers. Temperature controls ensure optimal consistency, while integrated sensors and programmable logic controllers oversee the entire process. This precision minimizes errors, reduces downtime, and maximizes throughput, resulting in enhanced productivity and cost-effectiveness for manufacturers.

In conclusion, the Liquid Filling Machine represents the epitome of efficiency and precision in liquid filling operations. Its exceptional features, versatile applications, and robust mechanical principles make it an indispensable asset for manufacturers seeking to streamline their production processes. By embracing this innovative technology, businesses can elevate their productivity, reduce costs, and deliver high-quality liquid products that meet the demands of today's competitive market.

This machine is suitable for filling a liquid and cream products, especially for high viscosity materials, the effect is obvious.

Meet food health standard, could filling tomato sauce , chili sauce , mayonnaise and so on.

1. Adopt PLC programmable control system with touch screen interface.

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

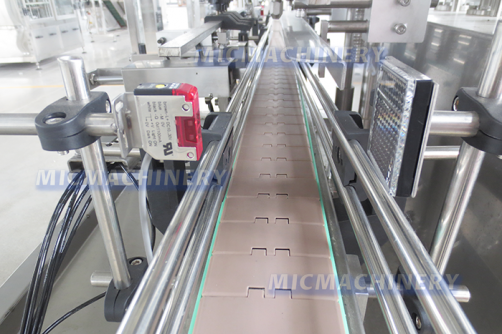

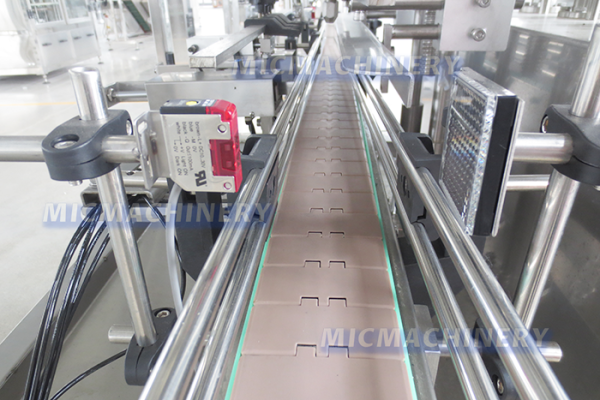

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time .

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved.On the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

Measuring cylinder

The function of measuring cylinder cylinder is mainly quantitative filling, its use can make your filling accuracy higher, driven by servo motor, control the movement of the piston rod, the Piston moving down extract the material from the material cylinder to the measuring cylinder cylinder, and then the piston moves up to the dose of the cylinder cylinder in the material to the filling pipeline.(The size of dose cylinder can be customized according to your needs)

Filling head

The shampoo is put into the material cylinder, the piston to pump the shampoo into the measuring cylinder. Then the piston moves up to send the shampoo to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling.After filling, the conveyor belt will automatically send the bottle to the capping station.(Filling process without drip leakage, the number of filling head can be customized according to your needs)

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: