- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This product is designed for packing various types of articles such as plastic wrap, aluminum foil wrap, and other similar materials of different specifications. The machine features PLC control, which ensures precise operation. It also incorporates photoelectric monitoring for the various action components. If any abnormal operation is detected, the machine will automatically stop, display the cause of the fault, and assist with timely troubleshooting.

The machine can be used independently or integrated with an aluminum foil cover to create a complete, automated production line.

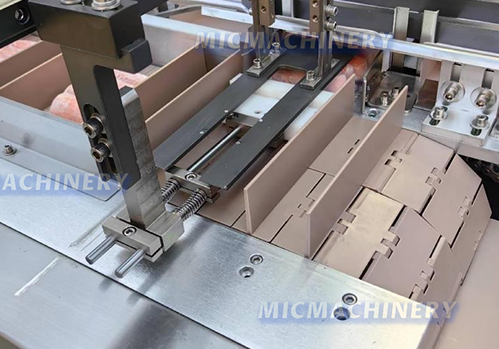

Mechanical Push Rod

Scale Adjustment Position Digital Display

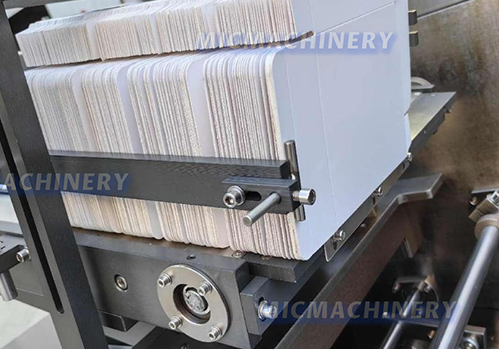

Station for Storing Paper Boxes

In the competitive world of packaging, speed, precision, and efficiency are paramount. The MIC-160 Automatic Cartoning Machine from MIC Machinery offers a cutting-edge solution for businesses looking to optimize their cartoning operations. With a capacity of 80 cartons per minute, this automatic cartoning machine is designed to streamline the packaging process, ensuring high-speed, reliable, and accurate carton formation, filling, and sealing.

Key Features of the MIC-160 Automatic Cartoning Machine

The MIC-160 Automatic Cartoning Machine is equipped with advanced features designed to maximize efficiency and minimize downtime. Here are some of the standout features of this horizontal cartoning machine:

1. High-Speed Operation: With an impressive filling capacity of 80 cartons per minute, the MIC-160 automatic cartoning machine ensures fast and efficient packaging. This high-speed performance makes it perfect for high-volume production environments, allowing manufacturers to meet demanding production schedules without compromising on quality.

2. Automatic Cartoning Process: This automatic cartoning machine automates the entire process, from carton forming to filling and sealing. The result is a seamless, labor-saving operation that reduces human error and enhances consistency in packaging.

3. Horizontal Cartoning Design: The horizontal cartoning machine design is specifically built to handle cartons that lie flat during the packing process. This design ensures easy product loading and improved flexibility when handling different carton sizes, making it ideal for various product types.

4. Precision Carton Forming and Sealing: The MIC-160 cartoning machine ensures that each carton is perfectly formed and securely sealed. This precise control helps avoid carton misalignment, weak seals, or misfilled products, ensuring high-quality packaging.

5. Versatile Application: The MIC-160 automatic cartoning machine is designed to accommodate a wide range of products. From pharmaceuticals to food and beverages, the machine can efficiently package a variety of goods, including bottles, pouches, and other packaged items.

6. User-Friendly Interface: With an intuitive control panel, operators can easily monitor and adjust the settings of the horizontal cartoning machine. The system is designed for quick setup, minimal downtime, and ease of operation.

6. Compact and Efficient: Despite its high-speed capability, the MIC-160 automatic cartoning machine is compact and space-efficient, making it suitable for businesses with limited floor space while maintaining high productivity.

Advantages of the MIC-160 Automatic Cartoning Machine

1. Increased Productivity: With the ability to pack up to 80 cartons per minute, the automatic cartoning machine significantly boosts production speed, helping manufacturers meet high-volume demands without sacrificing packaging quality.

2. Fully Automated Process: The automatic cartoning machine reduces the need for manual labor by automating the cartoning, filling, and sealing processes. This leads to improved operational efficiency, reduced labor costs, and a reduction in human errors.

3. Versatility: As a horizontal cartoning machine, the MIC-160 is capable of handling a variety of carton sizes and product types, providing flexibility in packaging different products in different industries. Whether it's bottles, cans, pouches, or other products, this machine can easily adjust to different packaging needs.

4. Precise and Consistent Carton Sealing: The MIC-160 cartoning machine ensures high-quality packaging with precise sealing and accurate filling, preventing issues such as misalignment or leakage that could compromise product integrity.

5. Cost-Efficient Solution: By automating the cartoning process, the automatic cartoning machine reduces the reliance on manual labor, leading to lower operational costs. Additionally, the fast production speeds contribute to higher output, making it a cost-effective solution for large-scale packaging operations.

6. Compact Design: The horizontal cartoning machine is designed to maximize space efficiency, allowing it to fit seamlessly into various production lines without taking up excessive floor space. This is ideal for facilities with limited space but high production needs.

7. Ease of Maintenance: The MIC-160 cartoning machine is built for ease of maintenance, ensuring minimal downtime and continuous operation. Its robust design reduces wear and tear, contributing to long-term reliability.

Conclusion

The MIC-160 Automatic Cartoning Machine is a high-speed, fully automated solution for efficient and reliable cartoning. Whether you're in the pharmaceutical, food and beverage, or consumer goods industry, this horizontal cartoning machine provides a versatile, fast, and cost-effective method for packaging your products. With its ability to pack up to 80 cartons per minute, precision carton forming and sealing, and automated features, the MIC-160 cartoning machine helps optimize your production line, reduce labor costs, and ensure consistently high-quality packaging.

If you’re looking for an efficient way to boost your cartoning operation, the MIC-160 automatic cartoning machine is the perfect choice.