- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Glue Filling and Capping Machine with Chuck and Conveyor: Streamlining Your Glue Packaging Process

The Glue Filling and Capping Machine with Chuck and Conveyor is an essential piece of equipment for businesses looking to streamline their glue packaging operations. This high-efficiency system is designed to fill, cap, and seal glue containers with precision and speed, making it an ideal solution for both small and large-scale production lines. Whether you're using a glue filling machine, a super glue filling machine, or a glue packing machine, this integrated system helps ensure consistency, high-speed output, and minimal waste in your packaging process.

Key Features of the Glue Filling and Capping Machine with Chuck and Conveyor

The Glue Filling and Capping Machine with Chuck and Conveyor offers advanced technology to enhance your production line's efficiency and precision. Here are some key features that make it stand out:

1. Automated Filling and Capping: The system combines both filling and capping operations into a single, seamless process, reducing manual labor and improving production speed.

2. Chuck Design for Secure Capping: The glue filling machine is equipped with a chuck mechanism to securely cap each container, ensuring that the caps are placed precisely and tightly for optimal sealing.

3. Integrated Conveyor System: The conveyor system efficiently moves containers from one station to the next, providing a smooth transition from filling to capping, which minimizes downtime and enhances overall production speed.

4. High-Speed Performance: This machine is designed to handle high-volume production, with a fast filling and capping rate, reducing the time needed to package large quantities of glue.

5. Versatile for Various Glue Types: Whether you are using a super glue filling machine for high-viscosity adhesives or a standard glue filling machine for lighter formulations, the system can accommodate different glue types, making it suitable for a wide range of applications.

Advantages of the Glue Filling and Capping Machine with Chuck and Conveyor

1. Increased Efficiency: The glue packing machine integrates both the filling and capping processes, significantly reducing cycle time and increasing productivity. The automated conveyor system ensures smooth, continuous operations, reducing the need for manual intervention.

2. High Accuracy: The glue filling machine uses advanced technology to ensure accurate and consistent filling volumes, minimizing product wastage and ensuring uniformity across all containers.

3. Secure and Tight Sealing: The chuck mechanism ensures that each cap is securely applied, preventing leaks or spills, and ensuring that the final product is sealed tightly for long-lasting quality.

4. Flexible for Different Glue Types: The system can be customized to handle various types of glue, including high-viscosity super glue and other adhesives, providing flexibility for different production needs.

5. Cost-Effective: By combining filling and capping in one machine, the glue packing machine reduces the need for multiple machines, lowering overall equipment costs while improving production speed.

Why Choose the Glue Filling and Capping Machine with Chuck and Conveyor?

1. Maximized Production Output: The automated system, combined with the high-speed filling and capping features, ensures that your production line runs efficiently with minimal downtime. With a continuous flow, your business can meet large orders quickly without sacrificing quality.

2. Precise and Consistent Filling: The glue filling machine ensures accurate and consistent filling of glue containers, providing uniform product quantities and reducing the likelihood of over- or under-filling.

3. Durability and Reliability: Built with robust materials and components, this machine is designed for long-term operation with minimal maintenance, providing a reliable solution for businesses looking to scale their production.

4. Ease of Operation: The glue packing machine is user-friendly, with easy-to-use controls and settings, allowing operators to quickly adapt and manage the machine with minimal training.

Conclusion

For businesses looking to optimize their glue packaging process, the Glue Filling and Capping Machine with Chuck and Conveyor offers an all-in-one solution. Whether you need a super glue filling machine for high-viscosity products or a standard glue filling machine for other adhesives, this system is designed to enhance efficiency, accuracy, and speed. By integrating both filling and capping into a seamless process, it reduces manual labor, improves production output, and ensures high-quality results. For companies seeking a reliable, high-performance glue packing machine, this machine is the ideal choice.

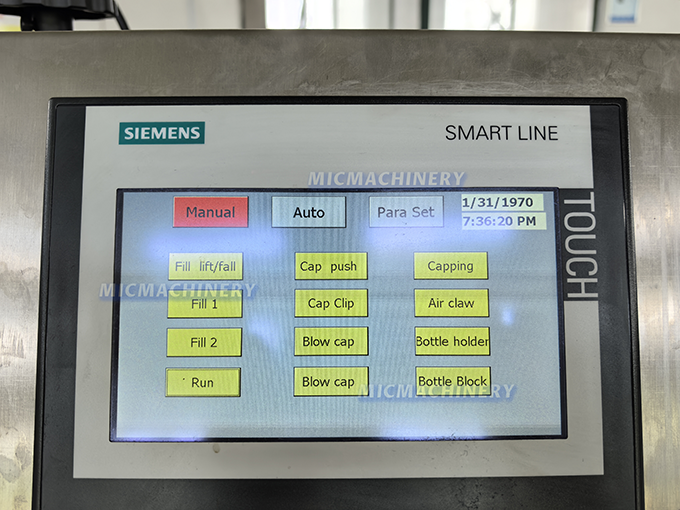

Control Panel

The control panel serves as the central hub for managing and operating the MIC Glue Filling and Capping Machine. It provides an intuitive interface for adjusting machine settings, monitoring real-time performance, and ensuring smooth operation. Through the control panel, operators can easily modify filling parameters, capping speeds, and conveyor adjustments, ensuring precise and efficient production with minimal downtime.

Filling Heads

The filling heads are designed to ensure accurate and consistent dispensing of glue into containers. Equipped with advanced technology, these heads deliver precise amounts of glue with minimal waste, ensuring uniformity across all units. The multi-head system allows for high-speed operation, boosting productivity while maintaining high standards of quality control in every fill.

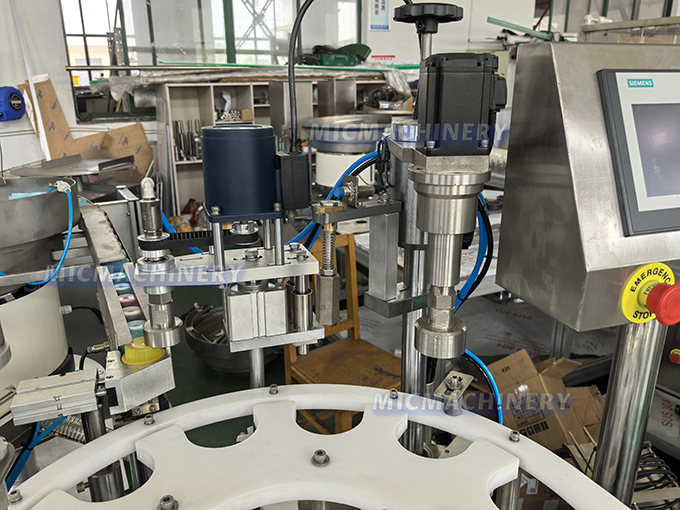

Screw Cap Station

The screw cap station automates the capping process, securely fastening caps onto the filled containers. The chuck and conveyor system guide the containers to the capping station, where the screw caps are applied with the perfect amount of torque to prevent leaks. This stage ensures a tight, reliable seal, preserving the product’s quality and ensuring that each container is securely capped for storage or shipment.

|

Filling volume |

100-1000ml (customize) |

|

Capacity |

30-40 bottles/hour |

|

Filling accuracy |

≤±1% |

|

Voltage |

380V/50Hz (Can customize) |

|

Automatic capping rate |

≥99% |

|

Air source |

1.3m3/h 0.4-0.8Mpa |

|

Power |

2kw |

|

Machine weight |

1000kg |

|

Size |

2400*1200*1900mm |

- MIC LL30 Semi-Automatic Glue Tube Filling Machine

- MIC M60 Glue Filling And Capping Machine (10-25 Bottles/Min)

- MIC-M30 Super Glue Filling Machine ( 502 Glue, Super Glue, 30-60 Bottles/min )

- MIC Glue Filling And Capping Machine (Super Glue, Glue 502, 30-40 Bottles/Min)

- MIC-L45 Glue Tube Filling Machine ( Toothpaste, AB Glue, 30-75 Tubes/min )

- MIC-L60 Automatic Glue Filling Machine ( Ointment, Cosmetic, 60-85 Tubes/min )

- MIC Glue Filling Machine ( AB Glue, Glitter Glue, 50 Bottles/min )

- MIC 502 Glue Filling Machine ( Super Glue, Glue 502, 30-60 Bottles/min )

- MIC Adhesive Filling Machine ( Super Glue, Super 502, 30-60 Bottles/min )

- MIC Cyanoacrylate Filling Machine ( Glue 502, AB Glue, 30-60 Bottles/min )

- MIC Glue Stick Filling Machine With Cooling Tunnel ( Glue, AB Glue, 20-40 Bottles/min )