- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

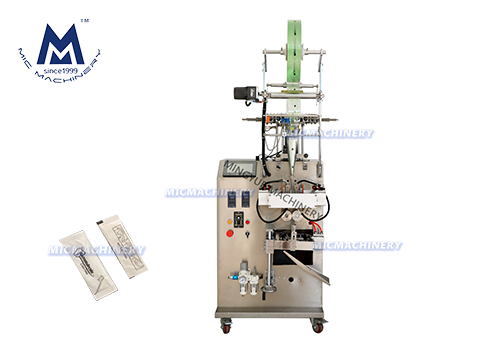

Congratulations on the development of the third generation automatic floss packaging machine! It's a significant achievement to build upon the advancements of previous generations and incorporate new research and experience into the latest product iteration. Securing a national patent design certificate underscores the innovation and uniqueness of your technology. This recognition highlights your team's dedication to pushing the boundaries of packaging automation.

Introducing the Cutting-Edge Dental Floss Packaging Solution: The Newest Model Dental Floss Packing Machine

In the realm of dental hygiene product packaging, precision, efficiency, and versatility are essential. The newest model dental floss packing machine emerges as a beacon of innovation, offering unparalleled performance tailored to the demands of modern dental care. Let's delve into its capabilities, emphasizing its prowess as an automatic pouch filling machine and pouch bag filling machine.

Precision Engineering for Seamless Operations

Accurate Filling Precision: The newest model dental floss packing machine is equipped with an advanced automatic pouch filling mechanism, ensuring precise dispensing of dental floss into individual pouches. With state-of-the-art dosing technology, it maintains consistent filling levels, guaranteeing uniformity across each package and optimizing product quality.

Swift and Efficient Operation: Engineered for high-speed performance, this machine facilitates rapid pouch filling, minimizing production time and maximizing throughput. Its automated functions enable seamless operation, reducing manual intervention and enhancing overall efficiency. Additionally, customizable settings allow for tailored adjustments to suit various production requirements, ensuring adaptability and responsiveness.

Versatile Packaging Solutions: With its versatility, the newest model dental floss packing machine accommodates a diverse range of pouch sizes, materials, and sealing methods. Whether filling standard pouches, stand-up pouches, or zip-lock pouches, it delivers consistent results while adapting to changing packaging needs. This flexibility allows for seamless integration into different production lines, optimizing resource utilization and minimizing downtime.

Elevating Dental Floss Packaging Standards

Powder Filling Packing Machine: As an automatic pouch filling machine, this cutting-edge equipment streamlines the packaging process by automating pouch filling, sealing, and labeling. Its precise filling mechanism ensures accurate product dosing, while automated sealing mechanisms guarantee secure pouch closure. By leveraging advanced technology, it enhances operational efficiency and product consistency.

Seamless powder packing machine: With dedicated capabilities for pouch bag filling, this machine caters to a variety of dental floss packaging requirements. Whether handling flat pouches, stand-up pouches, or custom pouch designs, it maintains product integrity while meeting packaging specifications. Its intuitive design facilitates smooth transitions between different bag types, enabling seamless production workflows.

Conclusion

The newest model dental floss packing machine represents a significant advancement in dental hygiene product packaging. With its precision engineering, swift operation, and versatile capabilities, it raises the bar for dental floss packaging standards. As both an automatic pouch filling machine and pouch bag filling machine, it offers a comprehensive solution for dental floss manufacturers, ensuring efficiency, consistency, and product excellence.

In the realm of dental hygiene product packaging, precision, efficiency, and versatility are essential. The newest model dental floss packing machine emerges as a beacon of innovation, offering unparalleled performance tailored to the demands of modern dental care. Let's delve into its capabilities, emphasizing its prowess as an automatic pouch filling machine and pouch bag filling machine.

Precision Engineering for Seamless Operations

Accurate Filling Precision: The newest model dental floss packing machine is equipped with an advanced automatic pouch filling mechanism, ensuring precise dispensing of dental floss into individual pouches. With state-of-the-art dosing technology, it maintains consistent filling levels, guaranteeing uniformity across each package and optimizing product quality.

Swift and Efficient Operation: Engineered for high-speed performance, this machine facilitates rapid pouch filling, minimizing production time and maximizing throughput. Its automated functions enable seamless operation, reducing manual intervention and enhancing overall efficiency. Additionally, customizable settings allow for tailored adjustments to suit various production requirements, ensuring adaptability and responsiveness.

Versatile Packaging Solutions: With its versatility, the newest model dental floss packing machine accommodates a diverse range of pouch sizes, materials, and sealing methods. Whether filling standard pouches, stand-up pouches, or zip-lock pouches, it delivers consistent results while adapting to changing packaging needs. This flexibility allows for seamless integration into different production lines, optimizing resource utilization and minimizing downtime.

Elevating Dental Floss Packaging Standards

Powder Filling Packing Machine: As an automatic pouch filling machine, this cutting-edge equipment streamlines the packaging process by automating pouch filling, sealing, and labeling. Its precise filling mechanism ensures accurate product dosing, while automated sealing mechanisms guarantee secure pouch closure. By leveraging advanced technology, it enhances operational efficiency and product consistency.

Seamless powder packing machine: With dedicated capabilities for pouch bag filling, this machine caters to a variety of dental floss packaging requirements. Whether handling flat pouches, stand-up pouches, or custom pouch designs, it maintains product integrity while meeting packaging specifications. Its intuitive design facilitates smooth transitions between different bag types, enabling seamless production workflows.

Conclusion

The newest model dental floss packing machine represents a significant advancement in dental hygiene product packaging. With its precision engineering, swift operation, and versatile capabilities, it raises the bar for dental floss packaging standards. As both an automatic pouch filling machine and pouch bag filling machine, it offers a comprehensive solution for dental floss manufacturers, ensuring efficiency, consistency, and product excellence.