- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of tube packaging, precision and efficiency are paramount for meeting production demands and ensuring product quality. Semi-automatic tube filling machines stand out as essential tools in this landscape, offering versatile performance tailored to the needs of various industries. Let's delve into their significance, focusing on their role as semi-manual tube filling machines, semi-automatic tube filling machines, and fully automatic tube filling machines.

Streamlining Production Processes

Precise Filling Capabilities: Semi-automatic tube filling machines provide precise filling capabilities, ensuring accurate dosing of products into tubes. Whether handling creams, gels, ointments, or pastes, these machines offer consistent fill volumes, maintaining product integrity and minimizing wastage. From pharmaceuticals to cosmetics, they cater to a diverse range of tube filling applications.

Efficient Operation: Designed for efficiency, semi-automatic tube filling machines optimize production processes while reducing manual labor. Operators can easily load tubes, fill them with the desired product, and seal them efficiently. Their semi-automatic functionality strikes a balance between manual control and automation, allowing for greater flexibility in production setups.

Versatility and Adaptability: Semi-automatic tube filling machines are highly adaptable to different tube sizes, materials, and product viscosities. With adjustable settings and interchangeable components, these machines accommodate varying production requirements with ease. Whether filling aluminum, plastic, or laminate tubes, they ensure reliable performance across diverse packaging formats.

Key Features of Tube Filling Machines

Manual Tube Filling Machine: manual tube filling machines offer operators greater control over the filling process while still benefiting from automated functions for sealing and trimming tubes. These machines are ideal for small to medium-scale production environments where flexibility and precision are paramount.

Semi-Automatic Tube Filling Machine: Semi-automatic tube filling machines automate the filling process to a significant extent, enhancing production efficiency while requiring minimal operator intervention. These machines feature user-friendly controls and intuitive interfaces, allowing for seamless operation and quick changeovers between different tube formats.

Fully Automatic Tube Filling Machine: Fully automatic tube filling machines offer the highest level of automation, handling tube loading, filling, sealing, and trimming processes with minimal human input. Ideal for high-volume production environments, these machines maximize throughput and ensure consistent fill volumes and sealing integrity across batches.

Conclusion

Semi-automatic tube filling machines play a vital role in optimizing production processes for various industries, offering a balance between manual control and automation. Whether as semi-manual tube filling machines, semi-automatic tube filling machines, or fully automatic tube filling machines, their performance streamlines tube packaging operations, enhances efficiency, and maintains product quality. By investing in these versatile solutions, manufacturers can achieve greater productivity, versatility, and competitiveness in their respective markets.

This machine is mainly used for plastic tube filling and sealing. It has been widely used in the fields of

pharmacy, cosmetic, food and chemical etc.

This machine function is:

1. Manual tube feeding

2. Automatic filling system

3. Automatic heating system

4. Automatic sealing system

5. Automatic cutting system

6. Automatic code print system

7. No tube no filling

8. No tube no sealing

9. Can be customized according to different tube shape and size

* Filling material: Grease & cream viscous liquids

* Filling method: Piston filling & peristaltic pump

* Sealing technology: hot air ( leister heating gun & copper heating)* Working flow: Tube feeding + mark orientation - measurable dosing + Tail sealing + code embossing + tail trimming -auto output to conveyor or carton

Tube filling and sealing machine used for plastic tube, soft tube. which is filling and sealing. filling volume is 5-250ml, the sealing is beautiful. The control place use PLC+ touch screen(SIEMENS). Other electrical parts use Schneider. These famous brand parts will ensure the good quality of the machine. Tube filling and sealing two in one machine with easy operation and low maintenance cost. Piston cylinder filling system, used for materials of different viscosities, filling precision is high. The control system is PLC and touch screen which guarantees stable. The material contact part is SS316, meeting the GMP standard.

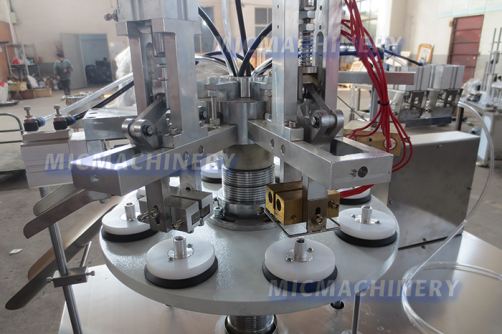

The main platform

Pictures include turntables, filling heads, sensors, heating heads, cutting and date printing stations. Its function is clear and easy to clean. Main workflow: automatic on-line through pipeline. When the pipe comes, the sensor automatically recognizes it, sends a signal to the gas station, and begins refueling. After filling, the end of the pipe is heated, flattened, cut, date printed, and finally the pipe is topped.

We can customize this turntable, filling head, etc

The control panel

The control panel on the filling machine is the core of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50 t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250Kg |

300Kg |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250Kg |

250Kg |

475Kg |

850Kg |

In addition to,If you're looking for cream tube filling machine,ointment tube filling machine,lami tube filling machine,plastic tube filling machine,toothpaste tube filling machine,cosmetic tube filling machine,small tube filling machine,collapsible tube filling machine,rotary tube filling machine,paste tube filling machine,soft tube filling machine,automatic ointment filling machine,ointment filling machine working,it is a pleasure for you to visit our website anytime.

In short,we will try our best to provide you with satisfactory service,the following is our client feedback:

|

Weight |

250Kg |

|

Dimension |

1230*700*1400mm |

|

Power |

220V/50Hz |

|

Motor |

1.1Kw |

|

Filling Quantity |

3-30ml/5-75ml/30-200ml |

|

Capacity |

20-30 Tubes/min |

|

Air Consumption |

<30 m³/min |

|

Heating Power |

400W |

|

Compressed Air |

0.6-0.8Mpa |

|

Quantity Error |

<2% |

| Parts | Brand |

|

Main Motor |

Wu XI Qi Peng |

|

PLC |

Panasonic JAPAN |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

BFNFC |

|

Intermediate Relay |

Schneider |

|

electromagnetic Valve |

Si Mai Ge |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

XiangGang Ease |

|

Air Cylinder |

Si Mai Ge |

|

Bearing |

Nsk |

|

Button |

Schneider |

|

Air Switch |

CHNT |

|

Power Switch |

Omron |

|

Temperature Control |

HuoYU |