- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of manufacturing, precision and efficiency are crucial for meeting consumer demands and ensuring product quality. Fully automatic tube filling machines stand out as essential tools in this landscape, offering unparalleled performance tailored to the exacting standards of the industry. Let's delve into their significance, focusing on their role as automatic tube filling machine, axomatic tube filling machine, and fully automatic tube filling machine.

Optimizing Filling Precision

Precise Tube Filling: Fully automatic tube filling machines are engineered to fill tubes with exceptional precision, ensuring accurate dosing and consistent product delivery. Utilizing advanced technology and precise filling mechanisms, these machines guarantee uniform fills across various tube sizes and formulations. Whether filling pharmaceutical creams, ointments, or cosmetic products, they ensure product integrity and customer satisfaction.

High-Speed Operation: Designed for high-volume production, fully automatic tube filling machines offer rapid filling speeds, maximizing throughput and minimizing production time. Their automated processes enable continuous tube filling, significantly reducing cycle times and increasing overall efficiency. With adjustable filling parameters and customizable settings, these machines adapt to the specific requirements of different product formulations.

Versatility and Adaptability: Fully automatic tube filling machines boast versatility in accommodating a wide range of tube materials, shapes, and sizes. Whether filling aluminum, plastic, or laminate tubes, these machines ensure seamless integration into diverse manufacturing processes. Their flexible design allows for quick changeovers between different tube formats, facilitating production versatility and minimizing downtime.

Significance in Manufacturing

Automatic Tube Filling Machine: Fully automatic tube filling machines play a crucial role in various industries, providing precise and efficient tube filling solutions for pharmaceuticals, cosmetics, and personal care products. Their automated processes streamline production workflows, ensuring consistent product quality and regulatory compliance.

Axomatic Tube Filling Machine: Axomatic tube filling machines are renowned for their reliability and performance in the tube filling industry. As fully automatic systems, they excel in delivering accurate fills and minimizing product waste. With their user-friendly interfaces and intuitive controls, Axomatic machines optimize manufacturing processes and enhance operational efficiency.

Fully Automatic Tube Filling Machine: Representing the pinnacle of tube filling technology, fully automatic tube filling machines offer unmatched performance and versatility. These machines integrate seamlessly into production lines, offering precise filling, capping, and sealing capabilities. Their advanced features and customizable options cater to the diverse needs of modern manufacturing environments.

Conclusion

Fully automatic tube filling machines serve as indispensable assets in modern manufacturing, offering precision, efficiency, and versatility in tube filling processes. Whether as automatic tube filling machines, Axomatic tube filling machines, or fully automatic tube filling machines, their performance optimizes production processes, enhances product quality, and ensures compliance with industry standards. By investing in these advanced filling solutions, manufacturers can streamline their production workflows, meet market demands, and maintain a competitive edge in their respective industries.

A soft tube filling and sealing machine(tube filling machine) is mainly used for plastic tube filling and sealing. It has been widely used in the fields of pharmacy, cosmetic, food, toothpaste, and chemical etc.

This machine(tube filling machine) function is:

1. Automatic tube loading

2. Automatic sensoring when the tube is coming

3. Then pistion filling for cream

4. Inner heating and outer heating

5. Tube sealing and date printing

6. Tail cutting automatically

7. Finishing and sealing check

This MIC-R60 auto soft tube filling & sealing machine is a 1 filling head filling machine with a heating gun. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

The control panel

The control panel on the filling machine is the core of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly.

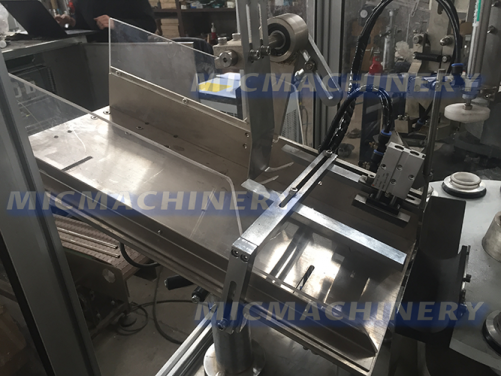

The main platform

Pictures include turntables, filling heads, sensors, heating heads, cutting and date printing stations. Its function is clear and easy to clean. Main workflow: automatic on-line through pipeline. When the pipe comes, the sensor automatically recognizes it, sends a signal to the gas station, and begins refueling. After filling, the end of the pipe is heated, flattened, cut, date printed, and finally the pipe is topped.

We can customize this turntable, filling head, etc

Automatic tube feeding system

Its main function is to make the pipes in order on the top, into the filling machine, the whole process can be controlled by the touch screen, the internal program will automatically complete the tube work. Effectively save labor cost.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50 t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250Kg |

300Kg |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250Kg |

250Kg |

475Kg |

850Kg |

In addition to,If you're looking for tube filling machine,automatic tube filling machine,tube filling machine manufacturers,tube filling machine price,manual tube filling machine,semi automatic tube filling machine,ointment filling machine,tube filling machine manufacturer,aluminum tube filling machine,aluminium tube filling machine,it is a pleasure for you to visit our website anytime.

In short,we will try our best to provide you with satisfactory service,the following is our client feedback: