- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

Mic Machinery offers high-precision semi automatic syringe filling equipment designed to meet the evolving needs of pharmaceutical, cosmetic, and chemical industries. Our machines ensure consistent, accurate, and efficient filling, making them ideal for businesses seeking reliability and precision.

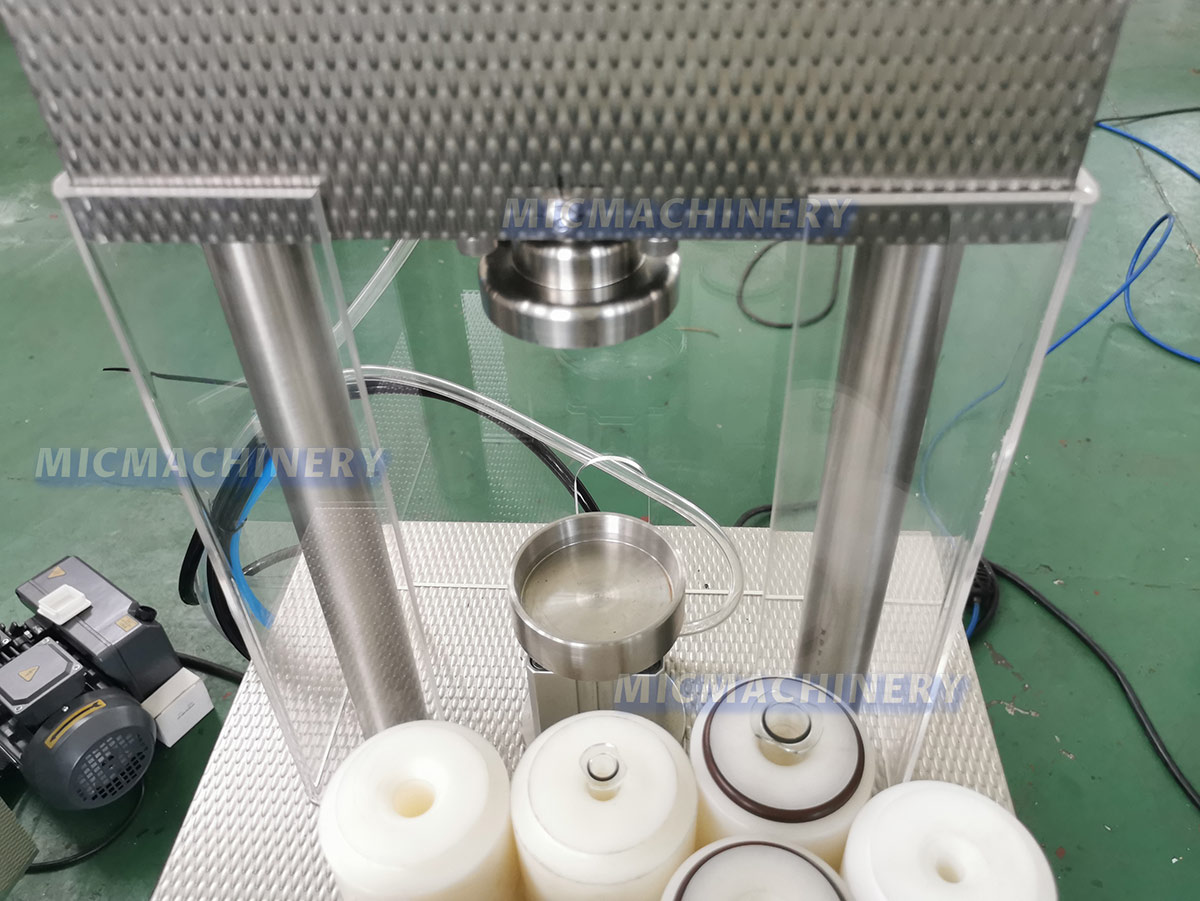

Syringe Mold

The syringe mold in semi automatic syringe filling equipment ensures accurate positioning and secure holding of each syringe during filling. It helps maintain consistent alignment, reduces spillage, and supports smooth operation across various syringe sizes and materials.

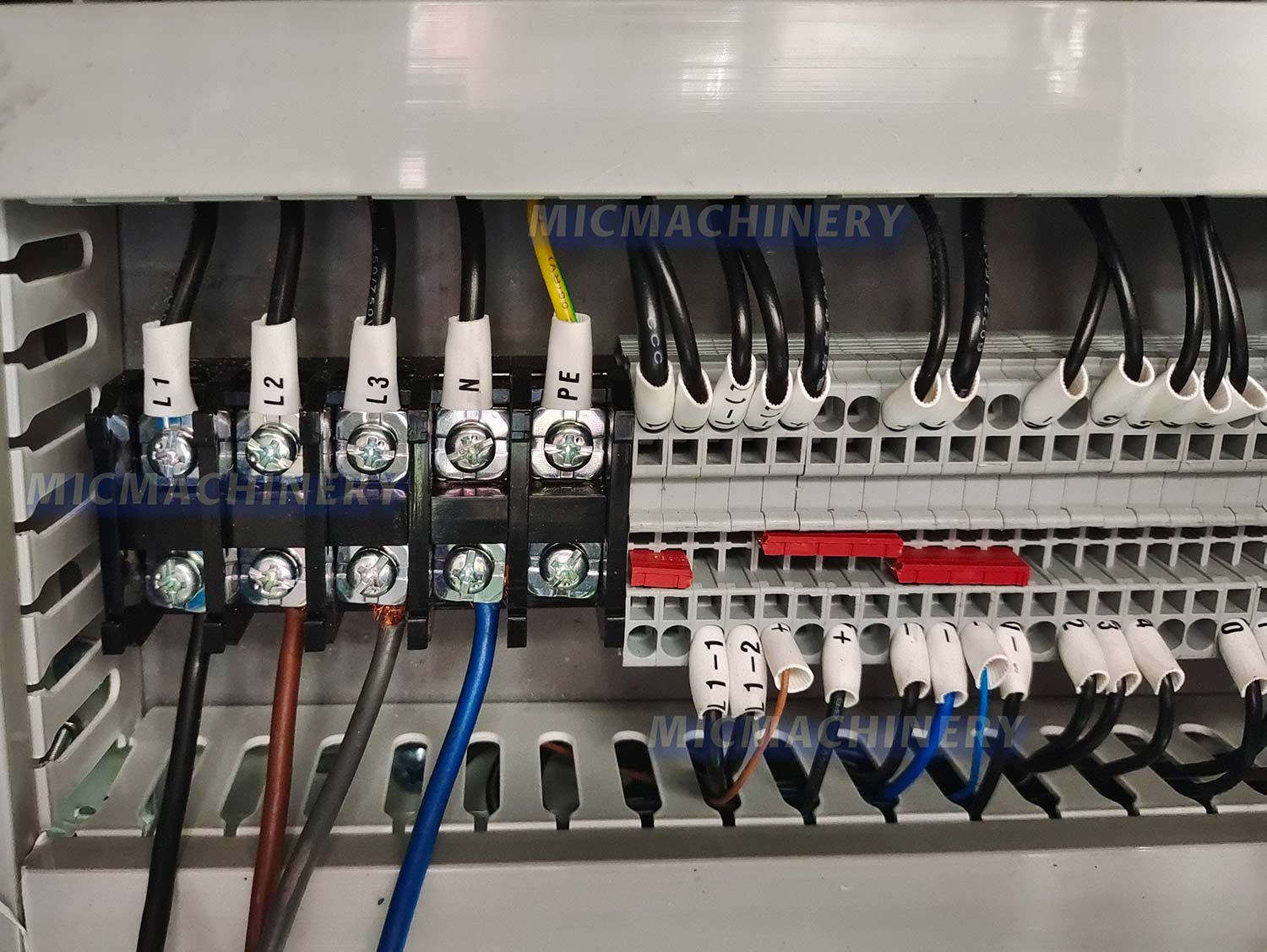

Circuit Board

The circuit board in semi automatic syringe filling equipment controls the entire filling process with precision. It manages timing, dosing, and system coordination, ensuring stable performance. A reliable circuit board enhances machine accuracy, safety, and overall operational efficiency.

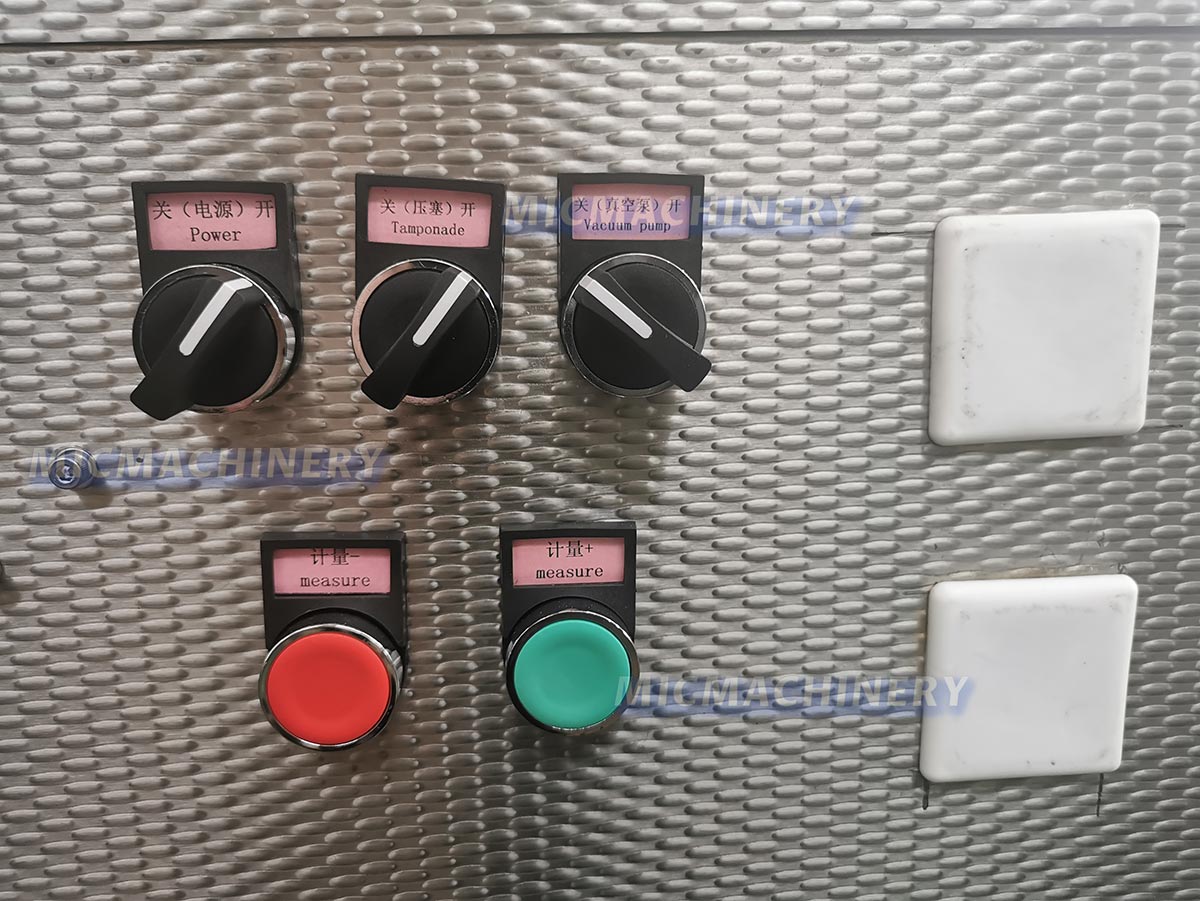

Control Panel

The control panel of semi automatic syringe filling equipment includes basic yet vital controls: power switch, tamponade switch, vacuum pump switch, and dosage adjustment buttons. Its intuitive design allows for precise and reliable operation during syringe filling.

What Is Semi Automatic Syringe Filling Equipment?

Semi automatic syringe filling equipment is a specialized solution for accurately dispensing liquids, gels, or viscous substances into pre-formed syringes. Unlike manual processes, it improves efficiency and reduces waste, all while maintaining product sterility. These systems are especially suited for small to medium batch production, R&D, and contract manufacturing environments where flexible and hygienic operations are essential.

At Mic Machinery, our semi automatic syringe filling machine integrates quality components and a user-friendly interface, enabling precise control over filling volumes. Designed with GMP compliance in mind, it ensures smooth integration into existing cleanroom setups or lab environments.

Key Features and Benefits

Our syringe filler machine models are built to deliver optimal performance across diverse syringe formats and product viscosities. Key advantages include:

● High Accuracy: Each machine is equipped with a precise dosing system, ensuring consistent filling across all units.

● Modular Design: Components can be adjusted or replaced to accommodate various syringe sizes or volumes.

● User-Friendly Operation: Simple controls and digital displays make operation easy, even for first-time users.

● Quick Changeover: Minimal downtime during product or size changeover enhances production flexibility.

● Hygienic Construction: All contact parts are made from pharmaceutical-grade stainless steel, supporting sterile processes.

These benefits make Mic Machinery’s semi automatic syringe filling equipment a top choice for companies aiming for safe and repeatable operations.

Applications Across Industries

The versatility of our semi automatic syringe filling machine makes it suitable for a wide range of industries and product types, including:

● Pharmaceuticals: Vaccines, analgesics, vitamins, and bioactive agents

● Cosmetics: Serums, gels, and skincare concentrates

● Veterinary: Animal health solutions such as dewormers and antibiotics

● Chemicals: Specialty adhesives, lubricants, and test reagents

Each application benefits from accurate dosing and clean filling, ensuring product safety and regulatory compliance.

Technical Configurations

Mic Machinery’s syringe filling systems are engineered for versatility and adaptability. Each syringe filler machine can be customized based on your product characteristics and production requirements. Key configuration options include:

● Filling Range Flexibility: Supports a wide spectrum of syringe sizes and fill volumes, adaptable to both low- and medium-volume production.

● Nozzle Options: Available with single or dual-nozzle setups to improve filling speed and accommodate different workflows.

● Control Systems: Equipped with user-friendly interfaces such as touch screens or PLC controls for precise parameter adjustments.

● Filling Mechanism Choices: Offers options like piston or peristaltic pumps to suit liquids of various viscosities, from watery solutions to thick gels.

● Optional Features: Add-ons include syringe stoppering, nitrogen purging, or heating units for temperature-sensitive or viscous products.

With these configurable features, every syringe filler machine from Mic Machinery is built to deliver both precision and operational efficiency across a wide range of applications.

Why Choose Mic Machinery?

Mic Machinery is a professional manufacturer of semi automatic syringe filling equipment, known for reliable performance and precision. Our semi automatic syringe filling machine is built for accuracy, durability, and easy integration into various production lines. We support our clients with expert guidance, technical service, and ongoing innovation to meet changing industry needs. Choosing our syringe filler machine means choosing a trusted partner in efficient syringe filling.