- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

MIC MIC-ZF4 Ampoule Filling Line: Precision and Efficiency in Pharmaceutical Packaging

Company Introduction

At Mic Machinery, we specialize in providing innovative, high-quality machinery for the pharmaceutical, food, and beverage industries. With years of expertise and a commitment to cutting-edge technology, we design and manufacture solutions that optimize production processes while maintaining the highest standards of quality. Our products, including the MIC MIC-ZF4 Ampoule Filling Line, are trusted by manufacturers worldwide for their reliability, efficiency, and precision. At Mic Machinery, we are dedicated to supporting the growth and success of our clients by delivering advanced automation solutions that meet the evolving demands of their industries.

Working Principle

The MIC MIC-ZF4 Ampoule Filling Line operates through a fully automated process that begins with the loading of empty ampoules into the machine. The line is equipped with an automatic feed system, which ensures the smooth and precise placement of ampoules into the filling station. Once the ampoules are securely in position, the ampoule filler begins the precise filling process, injecting the exact amount of liquid into each ampoule with high accuracy.

The system utilizes an advanced filling mechanism that employs volumetric filling technology to ensure consistency in each dose. After filling, the ampoules move through additional stations for sealing, capping, and labeling, depending on the configuration of the line. Throughout the process, the machine’s sophisticated control system monitors each step, ensuring optimal performance and minimal error. The design of the ampoule manufacturing machine allows for seamless integration into existing production lines, offering both flexibility and ease of use.

Function

The MIC MIC-ZF4 Ampoule Filling Line is designed to handle a wide range of ampoule filling tasks with precision and speed. Some of the core functions of the machine include:

· Ampoule Filling: The heart of the system is its ampoule filler, which provides high-precision filling with minimal product loss. It can handle a variety of liquid formulations, including injectables, vaccines, and other pharmaceutical liquids.

· Sealing: After the ampoules are filled, the machine automatically seals them to prevent contamination and ensure the integrity of the product.

· Capping: The system can also include a capping station for hermetically sealing ampoules, further protecting the contents.

· Sterilization: Depending on the configuration, the ampoule manufacturing machine can be equipped with a sterilization station to ensure that each ampoule is free from contaminants before reaching the market.

· Labeling: The line can also integrate automatic labeling equipment to apply precise, professional labels on each ampoule, ensuring that they are properly identified and compliant with regulations.

All these functions work together in a fully automated process that reduces human error, improves productivity, and ensures the highest standards of hygiene and quality control.

Advantages

The MIC MIC-ZF4 Ampoule Filling Line offers a variety of advantages that make it a top choice for pharmaceutical manufacturers:

· High Precision: The advanced ampoule filler ensures precise dosage for each ampoule, minimizing wastage and ensuring consistency across large production batches.

· Fully Automated Operation: With minimal human intervention, the ampoule filling line enhances productivity, reduces labor costs, and eliminates the risk of human error, providing greater operational efficiency.

· Versatile and Adaptable: Capable of filling a wide range of ampoule sizes and types, this system offers unmatched versatility, making it suitable for various pharmaceutical products.

· High-Speed Production: The MIC MIC-ZF4 Ampoule Filling Line is designed for high-speed operation, allowing manufacturers to scale up production while maintaining quality control and precision.

· Hygienic and Easy to Clean: With stainless steel construction and components designed for easy maintenance and cleaning, the machine adheres to the highest hygiene standards, ensuring safe and sterile conditions for pharmaceutical products.

· Energy Efficiency: The machine is designed to consume minimal energy without compromising performance, making it a cost-effective choice for manufacturers focused on reducing operational expenses.

· Safety Features: The system incorporates multiple safety mechanisms to prevent accidents and ensure the protection of both the operator and the product, providing peace of mind throughout the production process.

· Low Maintenance: Built with durable materials and high-quality components, the MIC MIC-ZF4 Ampoule Filling Line is designed for longevity and minimal maintenance, ensuring long-term reliability and reducing downtime.

In summary, the MIC MIC-ZF4 Ampoule Filling Line combines high precision, efficiency, and versatility with cutting-edge automation to meet the demanding needs of pharmaceutical manufacturers. Whether you're looking to improve your production capabilities or enhance the quality of your ampoule filling process, this machine provides a reliable solution for achieving your goals.

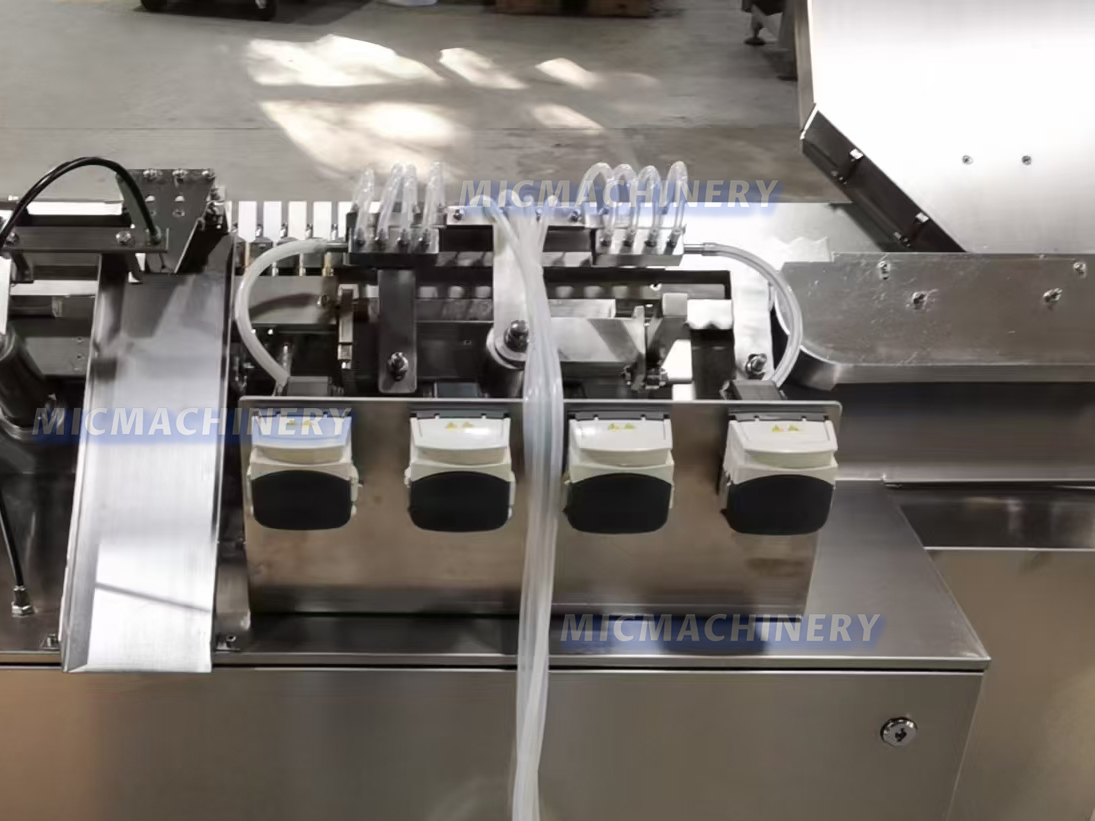

Filling Nozzles

The filling nozzles in an ampoule filling machine are designed for precise and contamination-free liquid dispensing. These nozzles ensure accurate filling volumes, minimizing waste and maintaining product consistency. Many models feature anti-drip and diving nozzles to prevent spillage and foaming, enhancing efficiency and ensuring high-quality ampoule production.

PLC Control

The PLC control in an ampoule filling machine offers advanced automation and precise control over the entire filling process. It ensures consistent operation, real-time monitoring, and error detection, improving efficiency, reducing downtime, and ensuring product quality throughout the production cycle.

Hopper

The hopper in an ampoule filling machine serves as the primary reservoir for liquid products before they are dispensed into ampoules. Designed for efficiency, it ensures a consistent flow of liquid, preventing interruptions during filling. Many hoppers feature temperature control and stirring mechanisms to maintain product stability and uniformity.

|

No. |

Item |

Parameter |

|

1 |

Model |

MIC-ZF4 |

|

2 |

Speed |

5000-7000pcs per hour |

|

3 |

Filling nozzels |

4 filling nozzles |

|

4 |

Packing material |

Glass ampoules |

|

5 |

Filling volune |

5-10ml |

|

6 |

Power |

0.75Kw |

|

7 |

Voltage |

220V single phase |

|

8 |

Machine Weight |

650Kg |

|

9 |

Dimension |

1650*1100*1350mm |

|

Item |

Brand |

|

PLC |

Siemens |

|

PLC mould |

Siemens |

|

Modular |

Siemens |

|

Touch Screen |

Siemens |

|

Peristaltic pump |

Watson Marlow |

|

AC contactor |

Schneider |

|

Motor |

Kinco |

|

Sensor |

Panasonic |

|

Buttons |

Schneider |

|

E-stop |

Schneider |

|

Power switch |

MeanWell |