- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the domain of plastic bottle packaging, precision and efficiency are essential for ensuring product integrity and streamlining manufacturing processes. The 8-Heads Linear Plastic Bottle Packing Machine emerges as a cornerstone solution, offering meticulous and efficient packaging for various liquid products. Let's explore how this equipment optimizes performance, focusing on its role as a plastic bottle filling machine, pet bottle filling machine, and plastic bottle packing machine.

Maximizing Performance with 8-Heads Linear Plastic Bottle Packing Machine

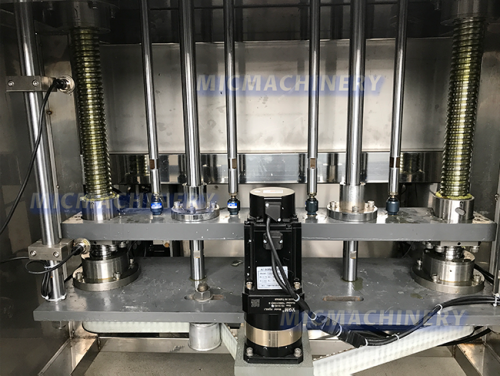

Accurate Bottle Filling: The 8-Heads Linear Plastic Bottle Packing Machine ensures precise and consistent filling of plastic bottles with liquids. Equipped with eight filling heads and advanced dosing mechanisms, this equipment delivers uniform filling levels, minimizing product wastage, and ensuring packaging integrity.

Efficient Production Process: Serving as a plastic bottle filling machine, this equipment streamlines the filling process, optimizing efficiency in manufacturing operations. With its linear configuration and multiple filling heads, it significantly reduces filling time, increasing production throughput, and minimizing downtime.

Reliable and Versatile Operation: As a plastic bottle packing machine, the 8-Heads Linear Plastic Bottle Packing Machine excels in reliability and versatility. Its adaptable design accommodates various bottle sizes and shapes, catering to diverse packaging requirements without compromising performance.

Serving as a Pet Bottle Filling Machine, Plastic Bottle Filling Machine, and Plastic Bottle Packing Machine

Pet Bottle Filling Machine: The 8-Heads Linear Plastic Bottle Packing Machine serves as a dedicated solution for filling PET bottles with liquids. Its precise engineering and multi-head design ensure accurate dosing and efficient filling, making it an indispensable asset in PET bottle filling operations.

Plastic Bottle Filling Machine: Tailored for filling plastic bottles, this equipment automates the filling process, optimizing packaging efficiency. Its intuitive controls and high-speed operation ensure seamless integration into production lines, maximizing throughput and minimizing manual intervention.

Plastic Bottle Packing Machine: With its comprehensive packaging capabilities, the 8-Heads Linear Plastic Bottle Packing Machine offers versatility and reliability in plastic bottle packaging applications. Whether packaging beverages, detergents, or pharmaceuticals, this equipment delivers consistent and high-quality packaging, meeting diverse market demands with ease.

Conclusion

The 8-Heads Linear Plastic Bottle Packing Machine represents a fusion of precision, efficiency, and versatility in plastic bottle packaging. Whether serving as a plastic bottle filling machine, PET bottle filling machine, or plastic bottle packing machine, it plays a crucial role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, manufacturers can streamline operations, reduce costs, and meet consumer demands with confidence.

This piston filling machine is suitable for:

Lube oil, engine car oil, industry oil, olive oil, bean oil, paint and other similar products.

This machine function is:

1. Automatic bottle sensing system and filling

2. No bottle no filling

3. Filling error is control within 1‰

4. Filling arrange : mini volume: max volume =1:10

5. Automatic filling volume correction system.

6. Can be customized for different bottle and caps.

7. Can be equipped with cleaning system.

This machine filling system is made for cosmetics package food bottle medical products and chemical products, easy clean and changes, we have automatic piston opening for cleaning. it is a practical machine for production and clean, 24 hours runs none stops, hardly have machine break down once well adjusted.

Machine filling accuracy max is at 1%, from 100ML-1000ML, 1L-5L volume, and it is piston filling controlled by servo motor.

This machine is mechanical transmission, controlled by servo motor, it is well developed machine, use life more than 15 years.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

Filling head

The sauce is put into the material cylinder, and the piston to pump the sauce into the measuring cylinder. Then the piston moves up to send the sauce to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Drip-proof air cylinder

For filling some materials that are easy to hang on the wall or sticky, the drip proof cylinder can effectively prevent the residual material inside the filling valve from dripping onto the bottle, keep the bottle clean and facilitate the labeling work later.

The working process is mainly as follows: after filling, the filling head moves upward, and the drip proof plate controlled by the drip proof cylinder extends out just below the filling head to catch the material left by the filling head

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

|

Filling Head |

8 heads |

|

Filling Volume Range |

50-1000ml(Use 1000ml piston cylinder) |

|

Production Speed |

≤1800 Bph basis on 1000ml bottle |

|

Voltage |

220v/380v |

|

Power |

3kw |

|

Suitable Bottle's Diameter |

Ф40mm-Ф100mm |

|

Filling Error |

≤±1‰ |

|

Work Pressure |

0.55Mpa-0.65Mpa |

|

Size |

2000mm × 1400mm× 2500mm |

|

Weight |

1000kg |

| Parts | Brand |

|

Touch Screen |

Canada Xinjie Color |

|

PLC |

Schneider |

|

Solenoid Valve |

Taiwan Airtac |

|

Optoelectronic System |

OPTEX |

|

Micro Differential Pressure Switch |

Netherlands |

|

Servo Motor |

Taiwan TECO |

|

Air Source Treatment |

Taiwan Airtac |

|

Button and Low Voltage Electric Appliance |

Schneider |

|

Ball Screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching Power Supply |

Taiwan Meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |