ALL PACK Exhibition in Indonesia: Innovations in Packaging Machinery

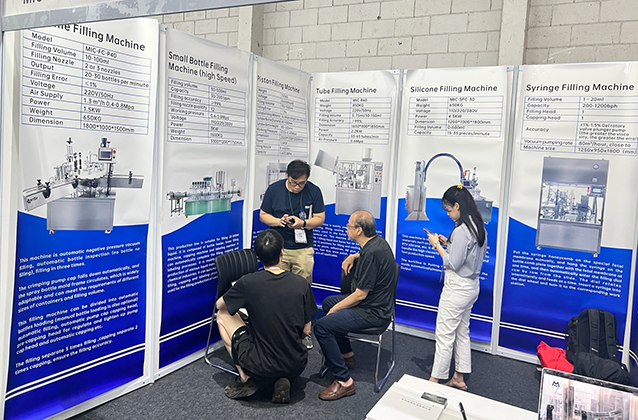

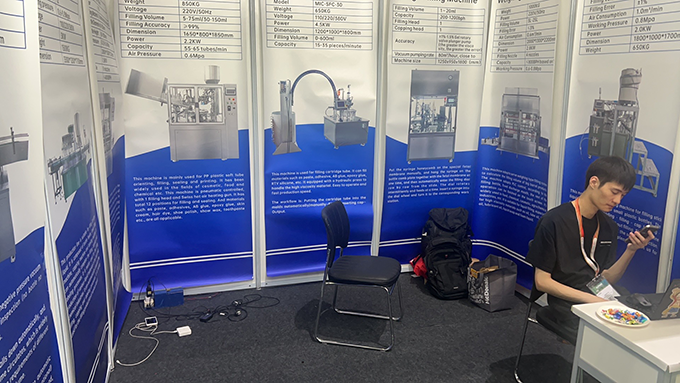

The ALL PACK exhibition in Indonesia, taking place on October 11, 2023, is a pivotal event for professionals in the packaging and processing industries. This exhibition gathers industry leaders, manufacturers, and innovators to explore the latest technologies and advancements in packaging machinery. We are excited to participate in this significant event, showcasing our high-performance machinery, including vial filling machines, tube filling machines, silicone filling machines, and cosmetic filling machines.Our Key Products

At the ALL PACK exhibition, we will highlight a range of advanced machinery designed to enhance efficiency and productivity across various sectors, particularly in pharmaceuticals and cosmetics. Here’s a closer look at our main products:

1. Vial Filling Machines Our vial filling machines are specifically engineered for the accurate filling of vials with a variety of liquids, including pharmaceuticals and cosmetics. Designed for precision and reliability, these machines ensure minimal waste and consistent filling volumes, crucial for maintaining product quality. With automated features, our vial filling machines streamline the production process, making them an essential asset for manufacturers in the healthcare and cosmetic sectors.

2. Tube Filling Machines Our tube filling machines cater to a wide range of products, including creams, gels, and ointments. These machines are designed for versatility and efficiency, handling various tube sizes and materials with ease. The automated filling process ensures quick changeovers and minimal downtime, enabling manufacturers to increase their production capacity. Our tube filling machines also incorporate advanced sealing technology, ensuring product integrity and preventing leaks.

3. Silicone Filling Machines Designed for filling silicone-based products, our silicone filling machines provide high precision and efficiency, making them ideal for applications in both the cosmetic and industrial sectors. These machines are equipped with state-of-the-art technology to ensure accurate dosing, reducing waste and ensuring product consistency. With customizable features, our silicone filling machines can adapt to different production requirements, enhancing operational flexibility.

4. Cosmetic Filling Machines Our cosmetic filling machines are tailored to meet the unique demands of the beauty and personal care industry. Capable of filling a wide range of products, from lotions and serums to powders and gels, these machines ensure precise filling and high-speed production. Designed with user-friendly interfaces and automated controls, our cosmetic filling machines streamline operations and enhance productivity, allowing manufacturers to meet the growing demands of the market.

Benefits of Attending the Exhibition

Participating in the ALL PACK exhibition offers numerous advantages for industry professionals. Here are some key benefits:

1. Networking Opportunities: Connect with industry leaders, suppliers, and potential clients to expand your professional network. Building relationships at the exhibition can lead to valuable collaborations and partnerships.

2. Discover Latest Innovations: Stay informed about the newest advancements in packaging machinery technology. Understanding emerging trends can help businesses innovate and adapt to changing market demands.

3. Live Demonstrations: Experience live demonstrations of our filling machines, showcasing their capabilities and efficiencies. Witnessing the machines in action allows attendees to assess their suitability for specific production requirements.

4. Educational Seminars: Attend informative seminars and workshops led by industry experts, covering critical topics such as production efficiency, regulatory compliance, and market trends. These sessions provide valuable insights to navigate challenges in the packaging and processing sectors.

5. Market Insights: Gain valuable market intelligence to inform your business strategies. Understanding the competitive landscape can help identify new opportunities for growth and development.

Article: Our Global Presence in Filling Machinery

Our company has established a robust global presence, successfully providing high-quality filling machines to manufacturers in numerous countries. This reach demonstrates our dedication to enhancing production efficiency in the pharmaceutical and cosmetic industries.

Key Markets for Our Machinery

1. France France is known for its vibrant cosmetic industry, and our filling machines play a crucial role in helping local manufacturers produce high-quality beauty products efficiently.

2. Italy Italy, recognized for its premium cosmetics and pharmaceuticals, utilizes our machines to maintain excellence in production while embracing innovative technologies.

3. Spain Spain's growing market for personal care products benefits from our advanced filling solutions, enabling manufacturers to scale operations and enhance product quality.

4. Netherlands With a strong emphasis on sustainability and innovation, the Netherlands relies on our filling machines to meet the needs of environmentally conscious consumers in the cosmetics sector.

5. Belgium Belgium's pharmaceutical industry values our precision filling machines, which ensure accuracy and compliance with rigorous quality standards.

6. Sweden Sweden's focus on eco-friendly products aligns with our machine capabilities, helping manufacturers produce high-quality, sustainable cosmetics.

7. South Africa As a leading market in Africa, South Africa benefits from our filling machinery to meet the demands of both local and international cosmetic and pharmaceutical markets.

8. Thailand Thailand's expanding beauty industry is rapidly adopting our filling machines to enhance production capabilities and cater to diverse consumer preferences.

9. Malaysia Our machines are crucial for Malaysia's growing cosmetic sector, helping manufacturers maintain high production standards and efficiency.

10. Vietnam Vietnam's burgeoning market for personal care products sees increased investment in our filling technology, allowing manufacturers to scale operations effectively.

11. Philippines The Philippines is experiencing a rise in demand for cosmetics, and our machines support local producers in meeting consumer expectations for quality and speed.

12. Egypt Egypt's pharmaceutical market benefits from our precise filling solutions, which help ensure the quality and integrity of critical health products.

13. Argentina Argentina’s expanding cosmetic market leverages our filling machinery to enhance production efficiency and meet local demands.

14. Colombia Our filling machines are instrumental in Colombia's beauty industry, enabling manufacturers to deliver high-quality products to consumers.

15. Chile Chilean manufacturers utilize our advanced filling machines to produce a wide range of cosmetic and pharmaceutical products efficiently.

16. Ukraine Ukraine’s focus on modernizing its manufacturing capabilities includes adopting our filling technology to improve production processes in various sectors.

17. Saudi Arabia As Saudi Arabia continues to grow its cosmetic and pharmaceutical industries, our filling machines support local manufacturers in enhancing production capabilities.

18. Israel Israel’s innovation-driven market benefits from our state-of-the-art filling solutions, helping local manufacturers maintain their competitive edge.

19. Japan Known for its commitment to quality, Japan utilizes our machines to ensure precision and reliability in the production of cosmetics and pharmaceuticals.

20. New Zealand New Zealand’s focus on natural and organic products aligns with our filling machines, which support manufacturers in producing high-quality, eco-friendly solutions.

Conclusion

Our commitment to delivering high-quality filling machinery has allowed us to expand our reach globally. By understanding the specific needs of each market, we continuously innovate our products to meet the highest standards of performance. Our filling machines play a vital role in optimizing production processes for manufacturers across various regions, helping them achieve their business goals in the pharmaceutical and cosmetic sectors.

The ALL PACK exhibition in Indonesia is an essential platform for professionals in the packaging and processing industries. Our commitment to high-quality machinery, including vial filling machines, tube filling machines, silicone filling machines, and cosmetic filling machines, aims to help manufacturers optimize their production processes and meet the evolving demands of the market.

By attending the exhibition, you can discover how our innovative solutions can elevate your business and enhance efficiency in your production lines. Whether you are a manufacturer seeking to upgrade your equipment or a professional looking for insights into the latest trends, this exhibition is an event you won’t want to miss. Join us in Indonesia to explore the future of packaging technology, where innovation meets quality and efficiency. Together, let’s shape the next generation of packaging solutions in the industry.

In today’s manufacturing landscape, the need for precision, efficiency, and consistency is paramount, especially in industries like pharmaceuticals, cosmetics, and food production. Filling machines play a critical role in ensuring that products are packaged accurately and securely. This article provides an in-depth exploration of four key types of filling machines: syringe filling machines, tube filling machines, silicone filling machines, and cosmetic filling machines. We will discuss their uses, features, and benefits, highlighting their importance in modern manufacturing.

Syringe Filling Machines

Syringe filling machines are specifically designed for filling syringes with liquid medications, vaccines, or other substances. They are widely used in the pharmaceutical and biotechnology industries, where accurate dosing and sterility are crucial.

Features

1. Aseptic Filling Systems: Many syringe filling machines maintain sterile conditions, ensuring that the product remains uncontaminated during the filling process.

2. High Precision: These machines use advanced dosing technology to deliver exact volumes of liquid, minimizing the risk of errors in medication dosages.

3. Compatibility with Various Syringe Types: Syringe filling machines can accommodate different syringe sizes and designs, including pre-filled and disposable syringes.

4. Automated Cap and Plunger Insertion: Some models include automated systems for inserting plungers and caps after filling, enhancing operational efficiency.

1. Enhanced Patient Safety: Precise filling reduces the risk of dosing errors, ensuring patient safety and compliance with health regulations.

2. Increased Production Speed: Automation in syringe filling processes allows for rapid production, helping manufacturers meet high demand.

3. Reduced Contamination Risk: Aseptic design features significantly lower the risk of product contamination during filling.

4. Scalability: These machines can be adapted to different production volumes, making them suitable for both small and large operations.

Tube filling machines are essential for the packaging of various products into tubes, such as creams, gels, ointments, and pastes. They are commonly used in the cosmetics, pharmaceutical, and food industries, where secure packaging is vital for product integrity.

Features

1. Automation: Many tube filling machines are fully automated, streamlining the filling and sealing process to maximize efficiency.

2. Versatile Tube Handling: These machines can fill different tube materials, including plastic, aluminum, and laminated tubes.

3. Accurate Volume Control: Advanced filling systems ensure consistent filling volumes, which is critical for maintaining product quality.

4. Sealing Options: Various sealing methods, such as ultrasonic sealing or crimping, ensure that tubes are securely closed and leak-proof.

1. High Efficiency: Automated processes significantly increase production speeds, allowing manufacturers to meet high-volume demands.

2. Cost Savings: Reduced labor costs and minimized product wastage lead to significant cost savings.

3. Improved Product Quality: Precise filling and sealing processes help maintain product integrity and shelf life.

4. User-Friendly Operation: Modern tube filling machines often feature intuitive interfaces, making them easy to operate and adjust.

Silicone filling machines are designed for filling containers with silicone-based products, such as sealants, adhesives, and caulking compounds. These machines are commonly used in the construction, automotive, and manufacturing sectors.

Features

1. High Viscosity Handling: Silicone filling machines are engineered to manage the thick, viscous nature of silicone materials without damaging the product.

2. Accurate Dispensing: They utilize advanced metering systems to ensure precise dosing, minimizing waste and ensuring consistency.

3. Flexible Container Compatibility: These machines can fill a variety of container types, including cartridges, tubes, and pouches.

4. Automated Capping Systems: Many silicone filling machines come equipped with automatic capping options for securely closing containers after filling.

1. Precision and Accuracy: Accurate dispensing of silicone ensures that the right amount of product is applied, which is crucial for performance in various applications.

2. Increased Production Efficiency: Automation enhances filling speeds, allowing manufacturers to ramp up production to meet demand.

3. Reduced Waste: Precise filling minimizes material waste, making the process more cost-effective.

4. Versatility: The ability to fill different container types allows manufacturers to adapt to varying product needs without significant downtime.

Cosmetic filling machines are used to fill a wide range of cosmetic products, including lotions, creams, serums, and gels, into various types of containers such as jars, bottles, and tubes. These machines are essential in the beauty and personal care industry.

Features

1. Multi-Head Filling Systems: Many cosmetic filling machines feature multiple filling heads, allowing for simultaneous filling of several containers to increase throughput.

2. Adjustable Filling Volumes: These machines can be calibrated to fill containers with different liquid volumes, ensuring accurate filling for various product lines.

3. Integrated Capper and Labeler: Modern machines often include automated capping and labeling systems, providing a complete packaging solution.

4. User-Friendly Controls: Most cosmetic filling machines come with intuitive control panels for easy operation and monitoring.

Benefits

1. High Versatility: Cosmetic filling machines can handle a variety of product types and container sizes, making them suitable for diverse product lines.2. Consistent Quality: Accurate filling mechanisms ensure that each container is filled to the same level, maintaining product quality.

3. Increased Productivity: High-speed filling capabilities significantly boost production rates, allowing manufacturers to keep up with market demands.

4. Cost Efficiency: Efficient filling processes reduce labor and material costs, leading to overall savings for manufacturers.

Filling machines, including syringe filling machines, tube filling machines, silicone filling machines, and cosmetic filling machines, are vital to the efficiency and success of manufacturing operations in various industries. Each machine serves a specific purpose, offering unique features and benefits that enhance production accuracy and product quality. By understanding the capabilities of these machines, manufacturers can optimize their production processes and meet the growing demands of their respective markets. As technology continues to evolve, these filling machines will likely become even more sophisticated, further advancing the landscape of manufacturing.