- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Description:

Effortlessly fill perfume bottles of various sizes with accuracy and consistency using our advanced machine. Whether you're crafting bespoke fragrances or mass-producing signature scents, our system ensures precise filling, minimizing product wastage and maximizing efficiency.

Experience seamless integration into your production setup with our user-friendly interface and customizable settings. With adjustable fill volumes and intuitive controls, you have complete flexibility to tailor the machine to your specific bottling requirements, ensuring seamless operations every time.

Boost your production efficiency and minimize downtime with the reliability and durability of our Perfume Filling Machine. Built to withstand the rigors of small-scale production, this robust solution delivers exceptional performance, ensuring consistent output and superior results.

Invest in performance, precision, and reliability with our Liquid Bottle Filling Machine. Stay ahead of the competition and meet the demands of today's market with ease. Contact us now to learn more about how this cutting-edge solution can elevate your small-scale perfume bottling process.

A semi-auto soft glue filling and capping machine is mainly used for glass bottle perfume filling and capping.

This MIC-L40 SEMI-auto perfume filling & capping machine contains a working disk and two vibrating plates. It has 3 filling heads and 16 positions.

Advantages:

Small and saving space

1.Efficient and precise

2.Easy to operate and flexible

3.Stainless steel body, neat and beautiful

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

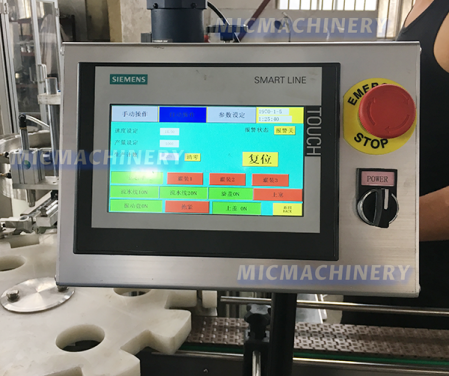

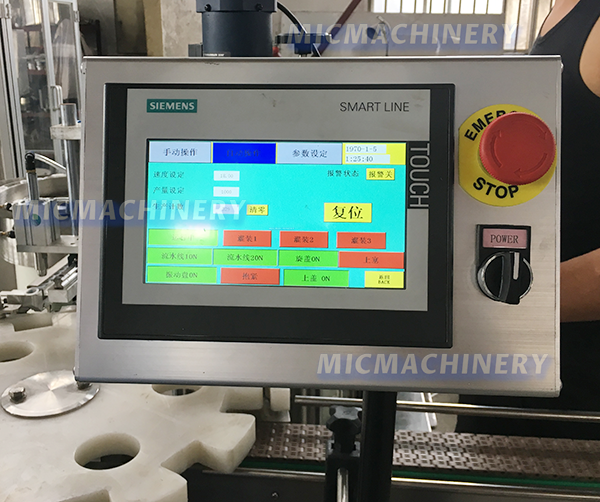

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

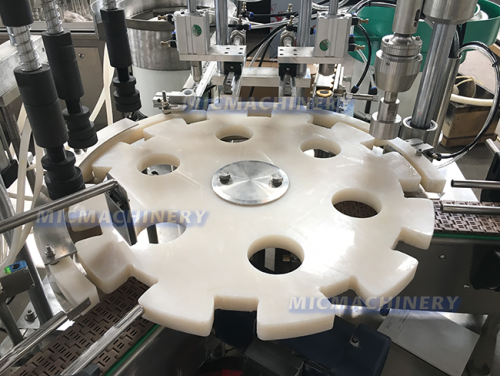

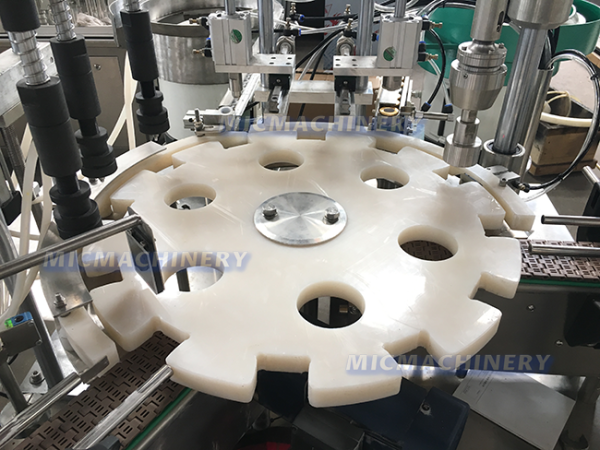

The main platform

The picture includes chuck, negative vacuum filling head,and automatic lid feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on.

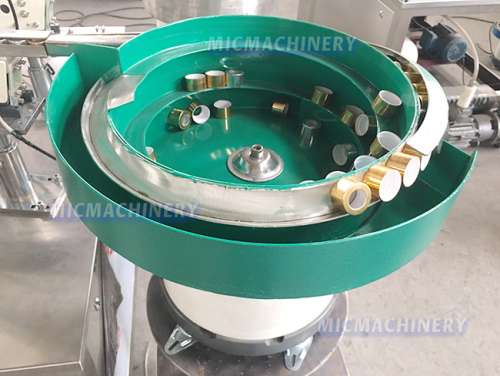

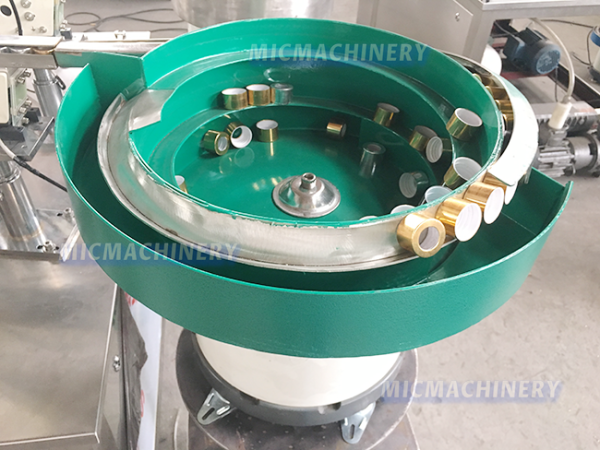

Cap loading automatically

Cap feeding cage with vibrating piate is connected to a pipe that carries the cap ,They automatically arranges the cap and deliver the cap.

In this way, the bottle is covered in a consistent process, reducing the manual contact with the bottle process, and ensuring better hygiene,At the same time, labor costs are reduced.

In short ,we will try my best to provide you with satisfactory serive, the following is our client feedback.