- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of fine fragrance craftsmanship, where artistry meets precision, the Perfume Filling Machine emerges as a cornerstone of innovation and efficiency. This cutting-edge technology seamlessly blends the ethereal notes of perfumes with advanced automation, redefining how these olfactory masterpieces are bottled and shared with fragrance enthusiasts worldwide. By delving into its distinctive product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we uncover the essence of olfactory excellence. From renowned perfume houses to boutique ateliers and cosmetic manufacturers, the Perfume Filling Machine ensures that every bottle encapsulates the essence of sophistication and luxury, elevating the fragrance experience with every spritz.

Product Characteristics:

The Perfume Filling Machine showcases exceptional characteristics meticulously engineered for precision and luxury. Crafted from high-grade stainless steel and adhering to rigorous quality standards, these machines ensure durability and maintain a sterile environment crucial for preserving the integrity of delicate fragrances. Featuring specialized dosing systems and precision nozzles, they accommodate a spectrum of fragrance viscosities, ensuring consistent and accurate filling for each bottle. Advanced sensors and intuitive control interfaces enhance operational efficiency, minimizing spillage and optimizing resource utilization. With anti-drip mechanisms and air-tight sealing, these machines preserve the freshness and complexity of perfumes, delivering an exquisite product to fragrance connoisseurs.

Product Applications:

The applications of the Perfume Filling Machine span the entire fragrance industry, from iconic perfume houses to bespoke artisanal perfumers. Large-scale manufacturers rely on these machines for efficient bulk production, ensuring uniformity in fragrance concentration and meeting the demands of the luxury retail market. Boutique perfumeries benefit from the precision of these fillers, enhancing the presentation and consistency of their signature scents. Additionally, cosmetic companies use Perfume Filling Machines for a variety of fragrance applications, from perfumes to scented lotions and body mists. Whether filling intricately designed bottles or sleek, minimalist vials, these machines cater to the diverse needs of the fragrance market.

Mechanical Principle:

At its core, the Perfume Filling Machine operates on advanced mechanical principles designed for delicacy, speed, and accuracy. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of perfume into individual bottles. Sealing mechanisms, employing high-speed capping or sealing technology, secure the packaging, preserving the freshness and allure of the fragrance. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of the filling and sealing operations.

Negative pressure filling

1. It can keep your finished product level at the same level with very little error. If your product container is made transparent, it can have a better visual effect in sales

2.It can be filled without dripping When filling without dripping, the cosmetic industry also needs to achieve a high standard of hygiene, negative vacuum filling without dripping to avoid the risk of cross infection

3.It is also very suitable for the filling of liquid which is easy to bubble during the filling process. Because this machine will suck all the foam in the bottle mouth at the end. The sucked foam and liquid will enter the liquid storage tank and it will not be wasted.

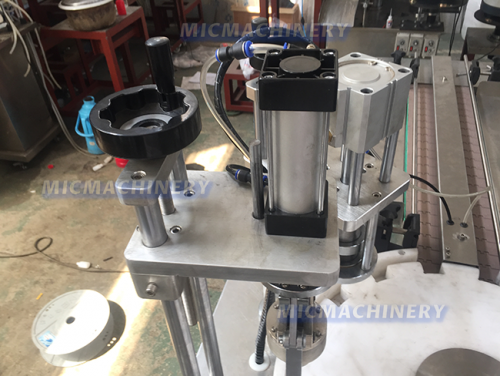

The machine’s chuck

The chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient and it is clear function and easy to clean.

We can customize the right tray for you for the size and shape of your packaging container

The main function is:

1.Negative pressure vacuum filling--It is easier to fill into small-mouth bottles to ensure the accuracy of filling and the consistency of liquid level.

2.putting cap manually(can be automatic)

3.crimping cap--The crimping nozzle is specially customized for spray caps to ensure no dripping.

The machine surface is made of stainless steel, which is beautiful, durable and easy to clean.

It very suitable for laboratory use or new market startup companies.

In addition to,If you're looking for perfume filling machine,perfume bottle filling machine,perfume bottling machine,automatic perfume filling machine,pocket perfume filling machine,perfume packaging machine,perfume machine,manual perfume filling machine,manual perfume filling machine price,it is a pleasure for you to visit our website anytime.

In short ,we will try my best to provide you with satisfactory serive, the following is our client feedback.

|

Filling Volume |

10-100ml |

|

Filling nozzle |

3 nozzles |

|

Output |

20-30 bottles each minute |

|

Filling Error |

≤±1% |

|

Power Supply |

220V/50Hz |

|

Capping Rate |

≥99% |

|

Air Supply |

1.3 m3/h 0.4-0.8Mpa |

|

Power |

2.0 kw |

|

Weight |

650 kg |

|

Dimension |

1800*1000*1500mm |

|

Button |

Schneider |

|

AC contactor |

Schneider |

|

Relay |

Schneider |

|

Frequency converter |

Taian |

|

Motor |

Qi peng |

|

Air cylinder |

AIR TAC |

|

Electromagnetic valve |

AIR TAC |

|

Bearing |

NSK |

|

PLC

|

Schneider

|

|

Touch screen |

Schneider |

|

Photoelectric detection |

Sick

|

- MIC Perfume Filling and Capping Machine

- MIC Liquid Filling Machine for Perfume

- MIC Perfume Filling Machine ( 20-30 Bottles/min )

- MIC-L40 Perfume Bottle Filling Machine ( 20-30 Bottles/min )

- MIC Perfume Packaging Machine ( 20-30 Bottles/min )

- MIC Perfume Bottling Machine ( 20-30 Bottles/min )

- MIC Manual Perfume Filling Machine ( 10-40 Bottles/min )