- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

It is widely used in adhesives, silicone, battery slurry, pharmaceutical, daily chemical, fine chemicals, petrochemical and other new polymer materials industry.

PROCTION INTRODUCTION:

a. Integrate mixture, dispersion and wall scraper in one machine

b. Mechanical seal, O ring seal or trapezoid seal for option material reaction can happen under vacuum condition

c. High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time. No deposit and residuals

d. Inverter control, various speed adjustment

e. Mirror polishing to ensure its smoothness

Brief Introduction:

High viscosity planetary mixer for silicone sealant is a high efficient equipment with a set of vacuum mixing and dispersion function together.

It can dissolve or mix powder, high viscosity and high density materials with a very high speed. This machine is especially suitable for lithium electricity experiment process for anode and cathode paste mixing process, and also other glue, chemical and other industries. And it can work with drum press to press material out from the mixing tank.

In the vibrant world of cosmetics, achieving precise and efficient mixing is a fundamental process for creating high-quality products with superior texture, consistency, and performance. Planetary mixers have emerged as indispensable tools in the cosmetics industry, offering advanced mixing capabilities that cater specifically to its diverse and demanding requirements. In this technical introduction, we explore the applications and benefits of planetary mixers in cosmetics production, highlighting their pivotal role in optimizing manufacturing processes and delivering exceptional cosmetic formulations.

planetary mixer for cosmetics are renowned for their ability to deliver precise and consistent mixing results, making them a preferred choice in the cosmetics industry. These mixers employ a unique mixing action that combines rotation and revolution, ensuring thorough blending of ingredients. The planetary motion of the mixing arm, rotating on its own axis while simultaneously orbiting around the mixing vessel, facilitates efficient dispersion and homogenization of cosmetic components. This precision is crucial for achieving uniform distribution of pigments, oils, emollients, fragrances, and other ingredients, resulting in consistent product quality and aesthetics.

laboratory planetary mixer exceptional versatility, making them ideal for a wide range of cosmetics applications. These mixers can handle different viscosities, consistencies, and volumes, accommodating various formulations such as creams, lotions, gels, serums, foundations, lipsticks, and more. Whether it involves blending colorants, emulsifying oils and water, incorporating active ingredients, or dispersing powders, planetary mixers provide the flexibility and adaptability required for diverse cosmetics production processes.

Efficiency and productivity are essential factors in cosmetics manufacturing. planetary mixer for cosmetics offer efficient mixing capabilities, reducing the overall processing time required for blending cosmetics ingredients. The combination of planetary motion, powerful motors, and purpose-designed mixing tools ensures rapid and thorough mixing, leading to improved production efficiency and increased throughput. This time-saving advantage enables cosmetics manufacturers to meet demanding production schedules and cater to the ever-growing market demands.

Cosmetics production demands consistent product quality to meet consumer expectations. planetary mixer in pharmaceutical industry contribute to this objective by ensuring consistent and uniform blending of ingredients. The precise mixing action promotes the homogeneous distribution of pigments, active ingredients, and texture-enhancing components, resulting in products with consistent color, texture, and performance. Additionally, advanced control systems in planetary mixers allow for precise monitoring and adjustment of mixing parameters, ensuring adherence to quality standards throughout the cosmetics manufacturing process.

Double Planetary Mixer Stirrer

When the planetary frame rotates, it drives the three stirring in the box, and the dispersion axis rotates around the barrel axis at the same time, so that the material is subject to strong shear and kneading effect, so as to achieve the purpose of full dispersion and mixing; There is a wall scraper on the planetary rack rotating with the planetary rack, close to the barrel wall continuous scraping, so that the barrel wall without retained material, improve the mixing effect

Double Panetary Mixer Charging Basket

This device can work under vacuum and can continuously discharge water and other volatiles. Therefore, it can be used as a degassing kettle. The barrel can be heated or cooled by oil and water circulation as required; steam heating can also be used. The heating temperature is displayed by the temperature controller on the control panel.

Because this device has good mixing, shearing and dispersing effects, it is especially suitable for solid-solid, solid-liquid, and liquid-liquid dispersion and mixing, so it is used in chemical, food, light industry, pharmaceutical, building materials and other industries Both can be widely used.

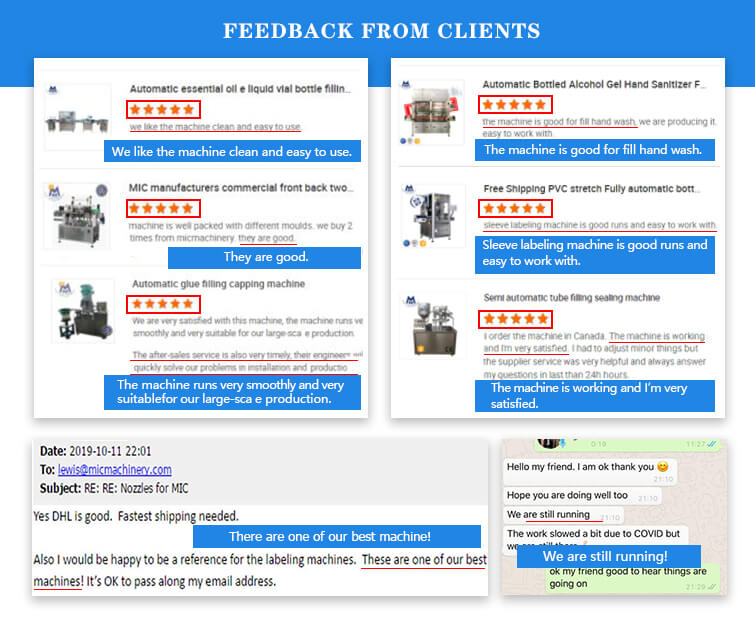

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Vessel(Dia. x Dep.) |

φ600x460 |

|

Full volume |

130L |

| Working Volume | 100L |

|

Dispersing power |

5.5KW |

|

Stirring Power |

7.5KW |

|

Stirring speed |

0-100rpm |

|

Scraper speed |

0-60rpm |