- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of hygiene product manufacturing, efficiency and precision are paramount, and the Hand Sanitizer Packaging Machine emerges as a pivotal asset. Seamlessly blending state-of-the-art technology with meticulous design, this innovative device offers hygiene product manufacturers a reliable solution for automating the packaging of hand sanitizer with accuracy and speed. Let's delve into the distinctive characteristics, versatile applications, and intricate mechanical principles of this transformative tool reshaping the hygiene product industry.

Product Characteristics:

The Hand Sanitizer Packaging Machine boasts a myriad of exceptional features meticulously engineered for precise and efficient packaging. Crafted from high-grade materials, it ensures durability and adherence to stringent quality standards. Equipped with fully automated packaging systems, customizable settings, and user-friendly interfaces, this machine provides seamless automation while allowing for control over the packaging process. Its adjustable controls accommodate various viscosities of hand sanitizer, ensuring each package receives a consistent fill. With anti-drip mechanisms and secure sealing, it preserves the integrity of the product, delivering hygienic solutions of unparalleled quality and reliability.

Product Applications:

The applications of the Hand Sanitizer Packaging Machine cater to the diverse needs of hygiene product manufacturers. Ideal for small to large-scale production, it excels in packaging hand sanitizer with precision and efficiency. Manufacturers leverage its versatility for custom packaging solutions, ensuring each product meets the highest standards of quality and safety. Whether filling bottles, pouches, or sachets, the Hand Sanitizer Packaging Machine serves as an indispensable tool for achieving hygiene product excellence with finesse.

Mechanical Principle:

At its core, the Hand Sanitizer Packaging Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing fully automated packaging mechanisms, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of hand sanitizer into individual packages. Temperature controls maintain optimal consistency, while integrated sensors and programmable logic controllers oversee the fully automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding the highest standards of hygiene product manufacturing.

In conclusion, the Hand Sanitizer Packaging Machine represents the epitome of synergy between technology and hygiene product expertise. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for hygiene product manufacturers seeking the perfect blend of precision and automation. As a cornerstone of hygiene product packaging, it continues to redefine industry standards, ensuring each package embodies the essence of precision, efficiency, and hygiene product excellence.

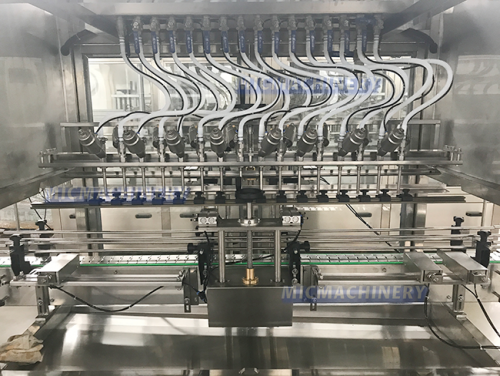

This machine is an automatic direct pressure vacuum filling machine. Mainly used in disinfectant liquid, pesticide, chemical, water, liquid bottles, sub packaging, can be applied to a variety of different shapes of containers.

The utility model can be matched with a capping machine and a labeling machine to form a flow production line.

It integrates light, electricity, electricity and gas. Control filling time to achieve different metering filling, filling time can be accurately controlled to one percent seconds. The filling process is completed on the touch screen under the control of the PLC program. It is a kind of easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability, can change the measurement to the specifications of filling in several minutes. Imported brand filling valve, advanced technology and precision, no leakage when filling.

Filling head

When the bottle reaches the designated position, the internal program controls the precise filling. The machine adopts self-flow filling, and automatically stops filling when reaching the filling standard. Very suitable for alcohol and disinfectant filling. Good filling effect and high working efficiency

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Drip-proof air cylinder

For filling some materials that are easy to hang on the wall or sticky, the drip proof cylinder can effectively prevent the residual material inside the filling valve from dripping onto the bottle, keep the bottle clean and facilitate the labeling work later.

The working process is mainly as follows: after filling, the filling head moves upward, and the drip proof plate controlled by the drip proof cylinder extends out just below the filling head to catch the material left by the filling head

Material box

The top of the machine is the material box, the material box is made of stainless steel, his capacity is large enough to reduce the number of times you add materials, this is very convenient.In addition, it is placed on the top of the machine to effectively save you more space.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.