- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the heart of honey production, where nature’s liquid gold meets craftsmanship, the Manual Honey Filling Machine stands as a testament to the harmonious blend of tradition and efficiency. This meticulously designed apparatus preserves the authenticity of honey while providing a seamless and manual filling process. Exploring its distinct product characteristics, versatile applications, and the fundamental mechanical principles guiding its operation reveals its pivotal role in the honey industry, ensuring each jar is filled with the pure essence of nature's sweetness.

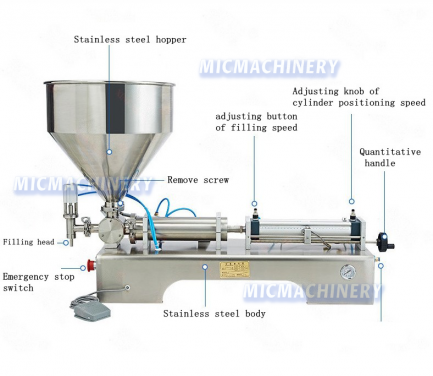

Product Characteristics:

The Manual Honey Filling Machine is defined by its unique product characteristics tailored for precision and simplicity. Crafted from durable materials, these machines guarantee longevity and resilience, with components chosen to withstand the stickiness of honey. Its ergonomic design ensures ease of use, allowing operators to fill jars effortlessly. The machine’s adaptability shines through its adjustable filling mechanisms, accommodating various jar sizes and honey consistencies. With a drip-free nozzle and airtight seals, it maintains the quality of honey, preventing spillage and ensuring the freshness of the product. Its intuitive controls and user-friendly interface enhance operational efficiency, making it an ideal choice for small-scale honey producers and artisans.

Product Applications:

The applications of the Manual Honey Filling Machine are versatile and indispensable, especially for boutique honey producers and local apiaries. This machine is the perfect choice for those valuing the artisanal touch in their honey production. Its manual operation makes it ideal for filling small batches of specialty honey, like rare floral varieties and infused blends. Craftsmen and artisans can use it to create limited edition or seasonal honey products, ensuring each jar is filled with care and attention. Moreover, farmers' markets, local stores, and gift shops benefit from its precision, offering customers the unique experience of purchasing honey filled by hand, adding a personal touch to each jar.

Mechanical Principle:

The Manual Honey Filling Machine operates on fundamental mechanical principles designed for simplicity and accuracy. Utilizing a manual lever or hand crank, the operator controls the flow of honey into individual jars. The machine features a precisely calibrated valve system that allows for controlled filling, ensuring each jar is filled to the desired level. A nozzle with an anti-drip mechanism prevents spillage between fills, maintaining cleanliness. The filling process relies on gravity, allowing the honey to flow smoothly without excessive force. This straightforward design minimizes the need for complex parts, making it easy to clean and maintain.

In conclusion, the Manual Honey Filling Machine embodies the essence of craftsmanship and precision in the honey industry. Its distinctive product characteristics, diverse applications, and fundamental mechanical principles make it an invaluable tool for artisans and small-scale producers aiming for authenticity and quality. Embracing tradition while embracing efficiency, this machine ensures that each jar of honey is a testament to the natural beauty and flavor of pure, unprocessed honey, making it a cherished choice for connoisseurs and enthusiasts alike.

1. Filling with piston pump. Driven by electricity and air compressor.

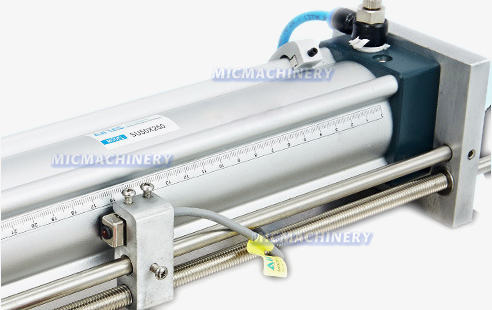

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

Filling Head

when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy.

The size of the filling head can be customized according to the caliber of the bottle, ensuring that this machine is absolutely suitable for your product.

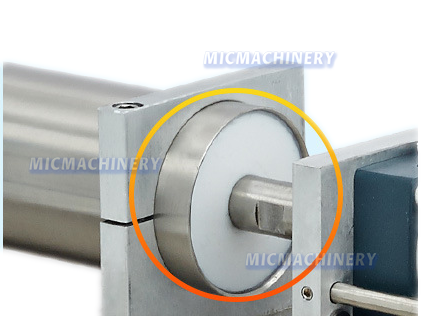

Air Cylinder

The cylinder is through the internal pumping system, the material out from the material cylinder, and then in the filling. Driven by electricity and air compressor.The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,If you're looking for honey filling machine,honey packaging machine,honey packing machine,honey stick filling machine,honey straw filling machine,honey bottling machine,honey stick machine,swienty filling machines,honey sachet packing machine,manual honey filling machine,it is a pleasure for you to visit our website anytime

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Model |

MIC V01 |

|

Voltage |

220V/380V 50/60HZ |

|

Power |

30W |

|

Air Pressure |

0.4-0.6MPa |

|

Filling Speed |

5-25 bottles/min |

|

Filling Accuracy |

±1% |

|

Dimension(L*W*H) |

1000*480*700mm |

|

Filling Range |

10-20ML. 25-250ML. 50-500ML.100-1000ML.250-2500ML. 1000-5000ML |

|

Weight |

35 Kg |

|

Filling Material |

Juice, Oil, Water, Sauce, Toothpaste, Cosmetic Cream, Hand Cream, Honey and etc |

|

Note: If you need special customization. please feel free contact me. |

|

- MIC-ZF6 Honey Packaging Machine ( Honey, Oil, Sauce, 1300-1500 Bottles/h )

- MIC Honey Stick Filling Machine ( Honey, Sauce, 20-40 Stick/min )

- MIC-V01 Manual Honey Filling Machine ( Honey, Oil, Juice, 5-25 Bottles/min )

- MIC Honey Filling Machine ( Honey Spoon, Yogurt, Sauce, 50-130 Spoons/min )

- MIC Rotary Honey Packing Machine ( Honey Spoon, Paste, 1200-1400 Spoons/h )

- MIC-ZG1 Honey Bottling Machine ( Honey, Paste, Mayonnaise, 1-50 Bottles/min )