- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

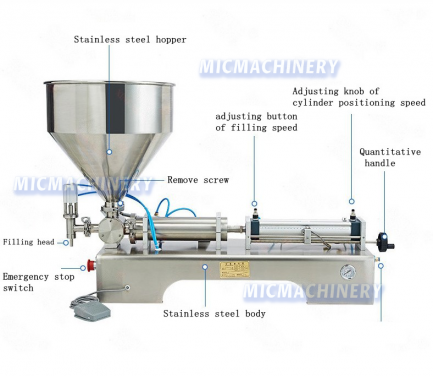

In the ever-evolving landscape of skincare manufacturing, efficiency meets innovation with the Lotion Bottle Filling Machine. Seamlessly integrating cutting-edge technology with precision engineering, this marvel of automation revolutionizes the process of filling lotion bottles. Let's explore its distinctive features, versatile applications, and intricate mechanical principles, all designed to optimize efficiency and quality in skincare production.

Product Characteristics:

The Lotion Bottle Filling Machine embodies a plethora of exceptional features meticulously engineered to streamline the filling process. Crafted from high-quality materials like stainless steel, it ensures durability and compliance with industry standards. Equipped with advanced automation, customizable settings, and intuitive interfaces, this machine offers seamless operation while maintaining control over the filling process. Its adjustable controls accommodate various lotion viscosities, ensuring consistent and accurate fills for every bottle. With anti-drip mechanisms and secure sealing, it preserves the integrity of lotion formulations, delivering products of unparalleled quality and craftsmanship.

Product Applications:

The applications of the Lotion Bottle Filling Machine cater to the diverse needs of skincare formulations. Ideal for medium to large-scale production, it excels in filling lotion bottles with precision and efficiency. Skincare manufacturers leverage its versatility for custom formulations, ensuring each bottle receives the perfect amount of product. Whether it's moisturizers, sunscreens, or specialty treatments, the Lotion Bottle Filling Machine serves as an indispensable tool for achieving skincare excellence with finesse.

Mechanical Principle:

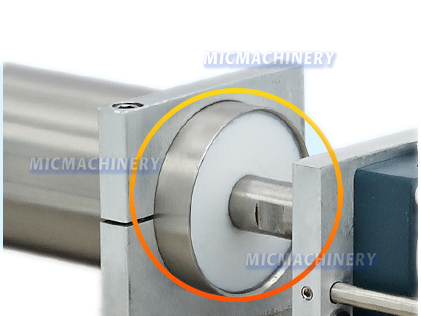

At its core, the Lotion Bottle Filling Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing automated dosing pumps, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of lotion into individual bottles. Temperature controls maintain optimal viscosity, while integrated sensors and programmable logic controllers oversee the entire process. This precision ensures uniformity, minimizes errors, and maximizes efficiency, all while upholding the highest standards of quality in skincare manufacturing.

In conclusion, the Lotion Bottle Filling Machine represents the pinnacle of efficiency and innovation in skincare production. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for skincare manufacturers seeking to optimize their production processes. As a cornerstone of modern skincare manufacturing, it continues to redefine industry standards, ensuring each lotion bottle embodies the essence of precision, efficiency, and quality.

1. Filling with piston pump. Driven by electricity and air compressor.

2. Filling volume can be easily adjusted.

3. The machine is all made of SUS304. Corrosion-resistant, compact structure, easy to operate, beautiful appearance, in line with GMP standards.

4. It can work automatically or controlled by a operation pedal.

5. Has single head, double heads and full pneumatic model. Our machine support special customization.

6. It is suitable for filling liquid and paste materials such as water, juice, oil, sauce, toothpaste, cosmetic cream, hand cream, honey, peanut butter etc. lt is widely used in chemical industry, food, cosmetic, medicine, etc.

if you want to know more models of filling machine, you can refer to the table below

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Model |

MIC V01 |

|

Voltage |

220V/380V 50/60HZ |

|

Power |

30W |

|

Air Pressure |

0.4-0.6MPa |

|

Filling Speed |

5-25 bottles/min |

|

Filling Accuracy |

±1% |

|

Dimension(L*W*H) |

1000*480*700mm |

|

Filling Range |

10-20ML. 25-250ML. 50-500ML.100-1000ML.250-2500ML. 1000-5000ML |

|

Weight |

35 Kg |

|

Filling Material |

Juice, Oil, Water, Sauce, Toothpaste, Cosmetic Cream, Hand Cream, Honey and etc |

|

Note: If you need special customization. please feel free contact me. |

|