- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

The Automatic Syringe Filler represents a cutting-edge solution in the pharmaceutical and medical industries, offering precise and efficient filling of syringes. Designed to streamline production processes and ensure dosage accuracy, this advanced equipment plays a pivotal role in pharmaceutical manufacturing. Let's delve into its features, benefits, and performance.

Put the syringe honeycomb on the special fetal membrane manually, and hang the syringe on the bottle comb plate together with the fetal membrane at one time, and then automatically enter the filling dial row by row from the slide. The dial rotates intermittently and feeds at a time. Insert a syringe into the dial wheel and turn it to the corresponding work station.

◆ Syringe filling Machine: the syringe is brought to the filling station by the dial, a single filling needle is inserted into the syringe and rises while filling, and the syringe is sealed at the same time for vacuum during filling. The filling pump uses a special gel ceramic pump Filling.

◆ Vacuum stoppering of the syringe: the filled syringe is rotated by the dial to the stoppering station. The rubber stopper is arranged by the oscillator and sent to the top of the syringe through the stopper track. A stopper rod first takes the rubber stopper on the stopper rod On the upper side, the stopper rod is integrated with a vacuum body, and at the same time, the syringe is pressed down to seal and vacuum, and then the stopper rod is added to the liquid level of the syringe.

◆ The finished product comes out: the finished syringe after filling and stoppering can be collected manually after being suspended and slipped out by a chute.

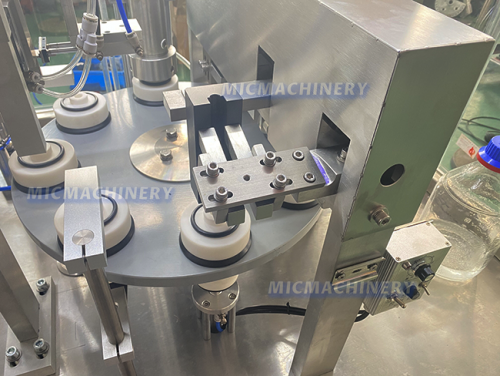

The main platform

The picture includes mould, filling head,and automatic inside plug loading and pressplug stations.They are clear function and easy to clean.

Among them, the mould is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient.We can customize this mould, filling head, and so on.

Inside plug loading automatically

Inside plug feeding cage with vibrating disk is connected to a pipe that carries the Inside plug ,They automatically arranges the Inside plug and deliver the Inside plug.

In this way, the syringe is covered in a consistent process, reducing the manual contact with the syringe process, and ensuring syringe hygiene,At the same time, labor costs are reduced

|

Syringe Filling Machine |

||||

|

model |

SGJ |

SGJ-1 |

SGJ-2 |

SGJ-3 |

|

application |

medicine, chemistry, biology,etc |

|||

|

Packing type |

various syringes, boosters, injection tubes,etc |

|||

|

speed |

5000pcs/h |

20-30pcs/min |

800-1000pcs/h |

800-1000pcs/h |

|

Filling arrange |

0.5-50ML |

5-100ML |

0.5-50ML |

0.5-50ML |

|

power |

3.5KW |

2KW |

2KW |

2KW |

|

size |

2500*1350*1600mm |

1380*1030*1800mm |

1800*800*1700mm |

1800*800*1700mm |

|

weight |

1500KG |

390KG |

450KG |

450KG |

In addition to,If you're looking for syringe filling machine,pre filled syringe filling machine manufacturers,syringe filling equipment,pfs filling machine,automatic syringe filler,syringe filling machine manufacturer,automatic syringe filling machine,syringe filling machine manufacturers,prefilled syringe filling machine,prefilled syringe machine,oral syringe filling machine,aseptic syringe filling equipment,sterile syringe filling machine,prefilled syringe machine manufacturers,syringe filling machine price.You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Volume |

1 ~ 20ml |

|

Capacity |

200-1200bph |

|

Filling Head |

1 |

|

Capping head |

1 |

|

Accuracy |

± 1%-1.5% Gel rotary valve plunger pump (the greater the viscosity, the greater the error) |

|

Vacuum pumping rate |

80m ³ /hour, close to |

|

Machine size |

1250x950x1800 ( mm ) |

- MIC-SFP-4 Automatic Syringe Filler (3000 Tubes/H)

- MIC Automatic Single Head Piston Syringe Filling And Capping Machine

- MIC Fully Automatic Teeth Whitening Syringes Filler

- MIC Pre Filled Syringe Filling Machine Manufacturers ( 800-1500 Syringes/h )

- MIC Syringe Filling Machine ( 5000 Syringes/h )

- MIC Prefilled Syringe Filling Machine ( 5000 Syringes/h )

- MIC Automatic Syringe Filler ( 200-1200 Bottles/h )

- MIC Pfs Filling Machine ( 10-30 Syringes/min )

- MIC Aseptic Syringe Filling Equipment ( 2000 Syringes/h )

- MIC Prefilled Syringe Machine ( 2000-3500 Syringes/h )

- MIC-SGJ1 Syringe Filling Equipment ( 20-30 Syringes/min )

- MIC Automatic Syringe Filling Machine ( 3000 Syringes/h )