- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

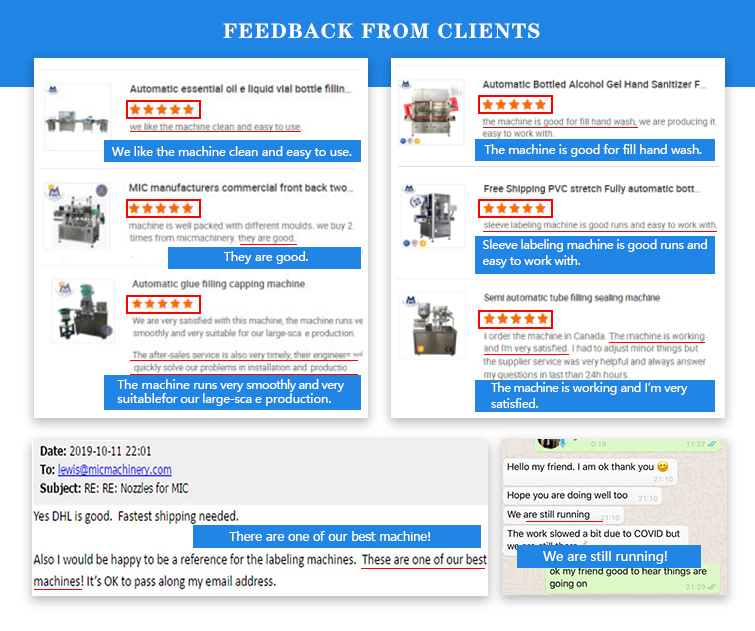

- Customer reviews: click on

horizontal labeling machine is specially designed and manufactured according to the principle and technical requirements of automatic labeling. Specially used for needle surface labeling; It has the advantages of compact structure, light weight, simple operation, reliable operation, convenient maintenance, fast labeling speed, smooth and beautiful labeling and strong adaptability. It is the best product in modern labeling machinery.

automatic syringe labeling machine can automatically attach the label to the designated position of the bottle; At the same time complete printing batch number, production date, production count. In the absence of bottles, the control system to ensure not to send labels, effectively prevent the waste of labels, and according to the production characteristics of each factory for the speed of stepless speed regulation, so as to ensure that the machine can be used alone or with other machines used in line, label pressing parts can make the surface of the bottle is not smooth to get satisfactory labeling effect.

Horizontal labeling function can adapt to various specifications, color, material of the needle, so the machine is widely used in medicine, food, light industry, beverage, daily chemical products and other industries.

Control Panel

All operations related to the touch screen are carried out in the "Manual screen" of the touch screen. Before debugging, click "Safety door Function" to close the safety door function

Blade

Click "Marking test" to observe the marking length, the label extends about 1mm out of the marking head. If the label is extended too long, release the nose photoelectric adjustment handle and move the photoelectric whole along the adjustment slot away from the marking edge. If the label is extended too little, move the photoelectric towards the marking edge.

Install The Label

Remove the upper label plate, screw the matsushita bracket fixing screw, adjust to the height required by the label, screw the fixing screw; Put the drum label on the label plate and the label plate tight ring, load the label plate, in the loose state of the material plate, pull out the label, according to the route marked in the schematic diagram, wear the drum label tape, the head is fixed on the receiving plate with a clamp, adjust the drum tight coil height to the position of the height; (The label should pass through the photoelectric slot in the nose).

Achieve Optimal Syringe Labeling Precision with a Horizontal Syringe Labeling Machine

Introduction:

In the pharmaceutical industry, accurate and efficient labeling of syringes is crucial for product identification, patient safety, and regulatory compliance. A horizontal syringe labeling machine offers a cutting-edge solution that ensures precise label placement on syringe bodies or caps. This article provides a technical overview of a horizontal syringe labeling machine, highlighting its key features and benefits. Discover how this advanced machine can elevate your syringe labeling processes with unparalleled precision and efficiency.

Horizontal Labeling Technology:

A horizontal syringe labeling machine utilizes innovative horizontal labeling technology to achieve exceptional precision. It ensures that labels are applied smoothly and accurately on syringe surfaces, even in challenging positions or uneven surfaces. This advanced technology minimizes label misalignment and improves overall label quality, enhancing readability and product aesthetics.

Versatile Labeling Options:

Horizontal syringe labeling machines offer versatile labeling options to accommodate various labeling requirements. Whether it's wrap-around labels, front and back labels, or spot labels, these machines provide flexibility to meet diverse product labeling needs. The ability to handle different label types and sizes allows pharmaceutical manufacturers to adapt quickly to changing market demands.

High-Speed Performance:

Efficiency and productivity are paramount in pharmaceutical production. A horizontal syringe labeling machine operates at high speeds, ensuring rapid and seamless label application without compromising accuracy. With adjustable labeling speeds, the machine can be optimized to match specific production requirements, minimizing downtime and maximizing throughput.

Advanced Label Detection and Alignment:

To achieve precise label placement, horizontal syringe labeling machines employ advanced label detection and alignment systems. These systems utilize sensors and vision inspection technology to detect the position and orientation of the syringe and label, ensuring accurate alignment during the labeling process. This ensures consistent label placement and eliminates errors caused by variations in syringe dimensions.

Intuitive Control and User-Friendly Interface:

Horizontal syringe labeling machines are designed with user convenience in mind. They feature intuitive controls and a user-friendly interface, allowing operators to easily set labeling parameters, adjust label positions, and monitor the labeling process. This simplifies machine operation, reduces training requirements, and promotes efficient and error-free labeling operations.

Compliance and Traceability:

Pharmaceutical manufacturers must adhere to stringent regulatory guidelines and maintain traceability throughout the production process. Horizontal syringe labeling machines support compliance by accurately applying labels with essential product information, such as barcodes, lot numbers, and expiration dates. This ensures regulatory compliance, facilitates inventory management, and enhances patient safety.

Conclusion:

Investing in a horizontal syringe labeling machine is a strategic choice for pharmaceutical manufacturers seeking unparalleled precision and efficiency in syringe labeling operations. With its advanced horizontal labeling technology, versatile labeling options, high-speed performance, precise label detection and alignment, user-friendly interface, and compliance support, this machine revolutionizes syringe labeling processes. Embrace the power of a horizontal syringe labeling machine to elevate your labeling precision and efficiency to new heights.

|

sryinge diameter |

Ф15-25mm |

|

length of the label |

Ф15-75mm |

| label speed |

0-200 bottles/min (depending on bottle size and label length) |

|

Maximum outer diameter of label roll |

Ф 300mm |

|

Inner diameter of label roll core |

Ф 76mm |

|

Single label interval |

≥3mm |

|

thickness of the label |

>8um |

|

engine power |

1100W |

| voltage |

220V/50 – 60HZ |

| engine size |

2900X550X1300mm |

| engine weight | 200kg |