- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

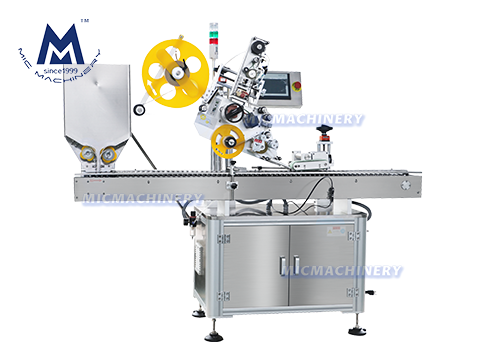

Operation system: The man-machine control 7 inch touch screen, directly visual interface easy operation, with Chinese and English two kinds language, also rich with the help function and fault display function ;

Check system: Use German LEUZE check label sensor, automatic check label station, stable and convenient don’t have much higher requirement for worker

Send label system:use SIEMENS high-power servo control system, stable with high speed;

Alarm function: such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

Machine Material: machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust;

Labeling way : use the servo send label system to send label on product surface; Low voltage circuit all use the German Schneider brand.

Key Features and Benefits:

* Unparalleled Labeling Precision: The china test tube labeling machine incorporates state-of-the-art optical sensors and advanced positioning systems, ensuring unparalleled accuracy in label placement on flat bottles. By eliminating errors and inconsistencies, this machine guarantees a professional and uniform appearance across all labeled bottles, bolstering brand image and customer trust.

* Versatility for Various Bottle Shapes: One of the standout features of the china test tube labeling machine is its remarkable versatility. It effortlessly accommodates a wide range of flat bottle shapes and sizes, including square, rectangular, oval, and elliptical containers. This adaptability makes it an ideal choice for businesses with diverse packaging requirements, enabling them to streamline their labeling processes without compromising on quality.

* Rapid Labeling Speeds: Time is of the essence in today's fast-paced production environments. The china test tube labeling machine excels in this aspect, boasting exceptional labeling speeds that can reach hundreds of bottles per minute. This high-speed operation significantly enhances overall productivity and efficiency, allowing businesses to meet growing demands and gain a competitive edge in the market.

* Intuitive User Interface: The china test tube labeling machine features a user-friendly interface designed to simplify operation and maximize efficiency. With intuitive controls and a straightforward setup process, operators can quickly configure labeling parameters, make necessary adjustments, and monitor the labeling process with minimal training. This intuitive interface minimizes downtime, optimizes workflow, and empowers operators to focus on other critical tasks.

* Enhanced Traceability and Compliance: In an era of stringent regulations and increased focus on product traceability, the china test tube labeling machine offers advanced features to support these requirements. It seamlessly integrates with barcode systems, QR codes, and other identification technologies, enabling businesses to track their products throughout the supply chain accurately. This enhances traceability, facilitates recall management, and ensures compliance with industry standards and regulatory guidelines.

* Durability and Reliability: The china test tube labeling machine is engineered with durability and reliability in mind. Constructed from robust materials and built to withstand demanding production environments, this machine delivers consistent performance over an extended period. Its reliability minimizes downtime and maintenance costs, providing businesses with a dependable labeling solution that ensures uninterrupted productivity.

Conclusion:

Investing in a china test tube labeling machine is a strategic decision for businesses looking to optimize their packaging processes and elevate their brand presence. With its unmatched precision, versatility, high-speed operation, user-friendly interface, and enhanced traceability features, this advanced labeling machine revolutionizes the way flat bottles are labeled, ensuring accuracy, consistency, and regulatory compliance.

By incorporating a china test tube labeling machine into their production lines, businesses can streamline their operations, increase productivity, reduce costs, and deliver exceptional packaging solutions that meet the highest industry standards. Stay ahead of the competition and unlock new opportunities with the remarkable capabilities of the Flat Bottle Labeling Machine.

Labeling worktable

Core principle: Sorting the product by bottle wheel, putting the product on the conveyor belt,sensors detect the product after, back to the signal to the labeling control system, in the appropriate position control system control corresponding motor send labels and attached with a stay in product labeling position, The product goes through the labeling device,the label belt drives the product to rotate, the label is rolled over, and the attached action of a label is completed.

A wheel for sorting bottles

Put a batch of bottles that need to be labeled to the location where the bottles are stored. The sorting wheel automatically sorts the bottles and sends the bottles to the specific conveyor belt in a horizontal way, with high working efficiency and great labor cost saving.

In addition to,If you're looking for tube labeling machine,vial labeling machine,vial sticker labeling machine,horizontal labeling machine,syringe labeling machine,Please feel free to visit our website.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

|

Model |

PWM-A |

|

Driving Mode |

Servo motor |

|

Yield(pcs/min) |

30-180 |

|

Operating direction |

Left or Right |

|

Conveyor Speed(m/min) |

≤40 |

|

Labeling Accuracy |

±1.0 mm |

|

The inner diameter of label roll |

76 mm |

|

The outer diameter of label roll |

350 mm(max) |

|

The suitable size of label |

Width 15-100 mm length 15-80 mm |

|

The suitable size of labeling objects |

Can customized depends on client product |

|

Printer use air |

5kg/cm 2 |

|

Voltage (In China) |

AC220V 50/60HZ Single phase (Can customized as client need) |

|

Power(w) |

600W |

|

Weight(kg) |

260 |

|

Machine size |

1800(L) 800 (W) 1300 (H) mm |

|

PLC control system |

SIEMENS |

|

Touch-screen |

SIEMENS |

|

Photoelectric sensor

(Check label object)

|

Japan KEYENCE |

|

Photoelectric sensor (Check opaque label) |

German Leuze |

|

Photoelectric sensor (Check opaque and transparent label) |

German Leuze |

|

Servo motor |

America AB |

|

Drive |

America AB |

|

Main transport motor |

German JSCC |

|

Roll label motor |

German JSCC |

|

Speed Controller |

German JSCC |