- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

beer can labeling machine Key Features And Benefits:

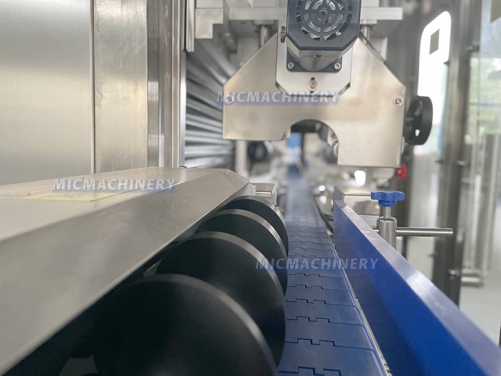

1. High Speed and Efficiency: beer can labeling machines are designed to handle high-speed production lines and can label up to thousands of containers per hour. The machine is equipped with advanced features like automatic feeding, orientation, and cutting, which ensures efficient and consistent labeling.

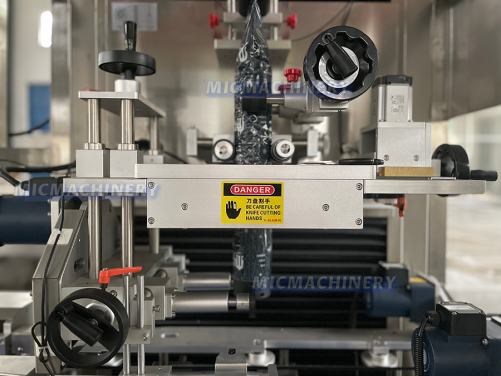

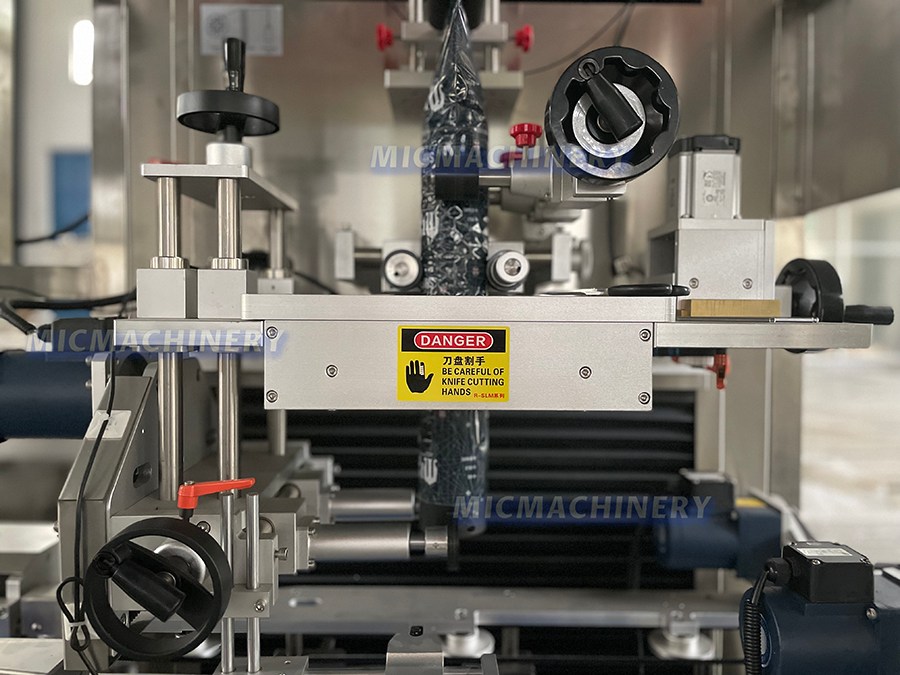

2. Accurate Labeling: An beer can labeling machine uses sensors and servo motors to ensure precise label placement and alignment, minimizing the risk of label errors. The machine can also detect and reject containers with incorrect or missing labels, ensuring accurate labeling for each container.

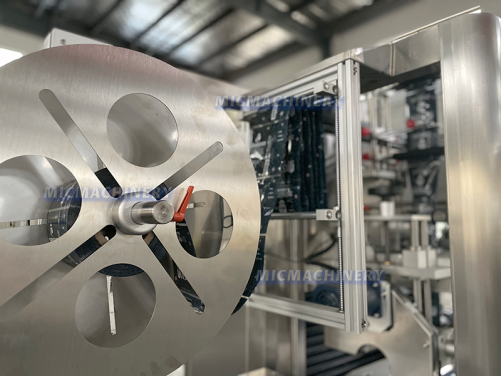

3. Versatile Labeling Options: An beer can labeling machine can handle different types of labels, including full-body sleeves, tamper-evident seals, and promotional sleeves. This versatility allows for greater flexibility in labeling options and enables companies to customize their labels according to their branding needs.

4. Cost Savings: The automation of the labeling process with a beer can labeling machine can significantly reduce labor costs and minimize material waste due to consistent and accurate labeling. This can lead to significant cost savings for the company.

5. Increased Production Capacity: The high-speed and consistent labeling provided by a beer can labeling machine can increase production capacity, allowing companies to meet growing demand and expand their business.

6. Improved Branding and Marketing: The full-body sleeves or promotional sleeves provided by the beer can labeling machine can improve branding and marketing efforts by providing a visually appealing and eye-catching label that attracts customers.

In summary, an beer can labeling machine offers many benefits, including high-speed and efficient labeling, accurate and consistent label placement, versatility in labeling options, cost savings, increased production capacity, and improved branding and marketing efforts.

|

Input power |

1.5KW |

|

Input voltage |

3380/220VAC |

|

Productivity |

Maximum 50 bottles/min (bottles/min) |

|

Host size |

2000Lx850Wx2000H |

|

Applicable bottle diameter |

50mm ~ 96mm |

|

Applicable label height |

30mm ~ 150mm |

|

Applicable label thickness |

0.03mm ~ 0.13mm |

|

Applicable inner diameter of paper tube |

5"~ 10" freely adjustable |

|

Name |

Amount |

Unit |

Brand |

|

PLC |

1 |

Tower |

Siemens |

|

Touch screen |

1 |

Tower |

Siemens |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

1 |

Tower |

Panasonic |

|

High-speed fiber optic sensor |

2 |

Tower |

Panasonic |

|

Servo motor for label delivery |

1 |

Tower |

Panasonic |

|

Servo drive for label delivery |

1 |

Tower |

Panasonic |

|

Cutter servo Motor |

1 |

Tower |

Panasonic |

|

Cutter Servo Drive |

1 |

Tower |

Panasonic |

|

Bottle divider |

1 |

Tower |

Panasonic |

|

Inverter with bottle |

1 |

Tower |

Panasonic |

|

Rack inverter |

1 | Tower | Panasonic |